In automotive manufacturing, especially for Hybrid and Electric Vehicles (EVs), panel sectioning techniques are vital for intricate designs requiring precision material handling and assembly. Modern technologies like laser cutting, robotic welding, and CNC machinery replace manual methods, offering unparalleled precision, efficiency, and structural integrity. Strategic implementation of these techniques streamlines EV and hybrid vehicle production, minimizing waste, enhancing quality control, and simplifying repair processes like dent or collision repair, resulting in safer, more efficient, and aesthetically superior vehicles.

In the rapidly evolving landscape of hybrid and electric vehicle (EV) manufacturing, efficient panel sectioning techniques are paramount. This article explores cutting-edge approaches to optimize hybrid and EV structures, focusing on panel sectioning methods that enhance assembly lines. From understanding unique material requirements to comparing traditional versus modern techniques, we delve into strategies that streamline production, reduce waste, and ensure structural integrity. Discover how these innovative panel sectioning techniques are revolutionizing the automotive industry.

- Understanding Hybrid and EV Panel Requirements

- Traditional vs Modern Sectioning Methods

- Optimizing Design for Efficient Assembly

Understanding Hybrid and EV Panel Requirements

In the realm of automotive manufacturing, especially with the rise of Hybrid and Electric Vehicles (EVs), understanding specific panel requirements is paramount. These vehicles often feature intricate designs that demand precision in material handling and assembly, particularly when it comes to panel sectioning techniques. Unlike conventional internal combustion engine (ICE) vehicles, Hybrids and EVs have unique structural considerations due to their battery packs, advanced propulsion systems, and weight distribution. Thus, panel sectioning techniques must accommodate these differences, ensuring structural integrity while facilitating efficient manufacturing processes.

Effective panel sectioning techniques for these structures involve tailored approaches that cater to the specific needs of hybrid and EV design. This includes strategies for managing high-strength materials, optimizing cuts for seamless welds or bonds, and addressing challenges associated with complex geometric shapes—all while minimizing waste and maximizing resource efficiency. Consideration must also be given to the subsequent vehicle body repair processes, akin to those in a car repair shop for vehicle dent repair or vehicle collision repair, ensuring that panel sectioning aligns seamlessly with these after-service requirements.

Traditional vs Modern Sectioning Methods

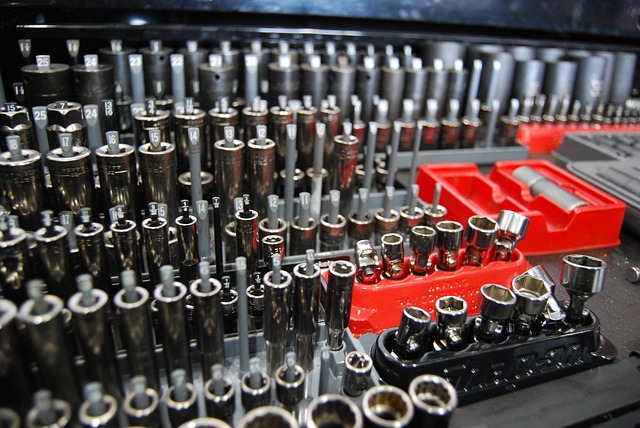

In the realm of panel sectioning techniques, a shift from traditional methods to modern approaches has revolutionized the automotive industry, particularly for hybrid and electric vehicles (EVs). Traditional panel sectioning often relied on manual, time-consuming processes involving heavy tools and precise measurements. This method, while robust, was cumbersome and left room for errors in complex vehicle structures. Modern panel sectioning techniques, however, leverage advanced technologies such as laser cutting, robotic welding, and computer numerical control (CNC) machinery to achieve unprecedented precision and efficiency.

These contemporary methods not only enhance structural integrity but also streamline the auto repair shop and vehicle body shop workflow. For instance, laser cutting allows for intricate and precise panel separation, reducing the need for manual labor and minimizing the risk of damage during car dent repair. Robotic welding ensures consistent and high-quality joints, while CNC machinery facilitates complex shaping and contouring, making it easier to handle the varied curves and contours found in modern vehicle designs. This evolution in panel sectioning techniques is a game-changer, fostering better manufacturing processes and ultimately contributing to safer, more efficient, and aesthetically superior vehicles.

Optimizing Design for Efficient Assembly

In the realm of hybrid and electric vehicle (EV) construction, efficient assembly is paramount to achieving streamlined production processes and cost-effective manufacturing. One key strategy lies in the strategic implementation of panel sectioning techniques, which play a pivotal role in simplifying and optimizing the overall design. By segmenting various components into manageable panels, manufacturers can facilitate precise assembly, reduce material waste, and streamline quality control measures.

This approach ensures that complex structures, such as body panels, are pre-fabricated into distinct sections, allowing for easier handling and efficient fitting during the auto glass repair or car collision repair processes. Panel sectioning techniques enable a modular assembly line, where specific panels can be assembled, tested, and integrated independently, thereby minimizing downtime and enhancing overall production efficiency. This method is particularly beneficial in addressing the unique challenges posed by EV and hybrid vehicle manufacturing, ensuring that intricate systems are built with precision and speed, akin to operations in a top-tier auto collision center.

Panel sectioning techniques play a pivotal role in shaping the efficiency and structural integrity of hybrid and electric vehicle (EV) structures. By understanding the unique requirements of these vehicles, transitioning from traditional to modern sectioning methods offers significant advantages in assembly and overall performance. Optimized design strategies ensure streamlined manufacturing processes, resulting in lighter, more robust vehicles that contribute to the sustainability and success of the automotive industry’s shift towards electrification.