Squeeze-type resistance spot welding is a cutting-edge method for restoring luxury vehicles, offering precise pressure and heat control to fuse metal without distortion. Ideal for body panel alignment and paint repair, it preserves original finishes and structures, ensuring restored cars maintain aesthetic and functional excellence. This non-destructive technique, using specialized tools, creates strong welds in thin sheets, minimizing heat input and preserving intricate details.

Squeeze-type resistance spot welding is a specialized technique gaining traction in luxury vehicle restoration, offering precision and strength. This article explores how this advanced method enhances the precision and quality of restorations, ensuring longevity and aesthetic appeal. We’ll delve into the process, its benefits, and the unique tools required for achieving flawless results. Discover why resistance spot welding is revolutionizing luxury car restoration practices.

- Understanding Squeeze-Type Resistance Spot Welding

- Benefits for Luxury Vehicle Restoration

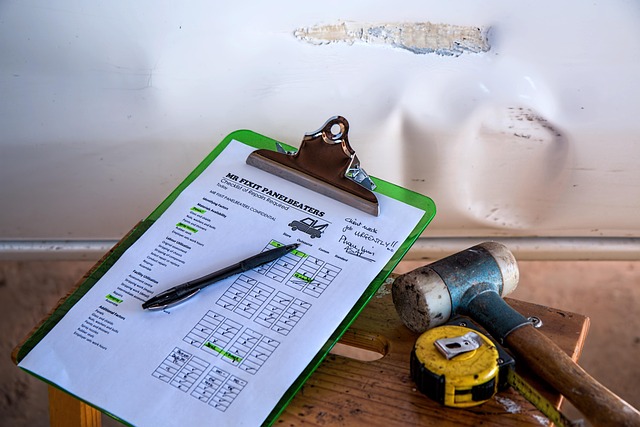

- Techniques and Tools Used in the Process

Understanding Squeeze-Type Resistance Spot Welding

Squeeze-Type Resistance Spot Welding is a specialized technique that has gained significant importance in luxury vehicle restoration. This advanced method involves using precise pressure and heat to fuse metal surfaces together, creating strong and durable bonds. By applying controlled force, this process ensures minimal distortion of the original material, making it ideal for restoring intricate automotive components without compromising aesthetics.

In the context of vehicle paint repair, Squeeze-Type Resistance Spot Welding plays a pivotal role in aligning and fusing damaged or separated body panels. Unlike traditional auto repair services that might rely on more invasive methods, this welding technique allows for precise adjustments, preserving the original finish and structure of the vehicle. As a result, it becomes an indispensable tool in high-end auto maintenance, ensuring that restored luxury vehicles not only look but also perform like new.

Benefits for Luxury Vehicle Restoration

Squeeze-type resistance spot welding offers several advantages for luxury vehicle restoration, setting it apart from traditional joining methods. Its precision allows for seamless integration of parts, preserving the original aesthetic and quality of the car’s design. This non-destructive technique ensures minimal heat input, protecting the intricate details and finishes that define luxury vehicles. By eliminating issues like paint damage or warping during the repair process, resistance spot welding is ideal for meticulous restoration work.

Moreover, this method facilitates quick and efficient repairs, which is crucial in high-end car body shops catering to demanding clients. The ability to precisely control weld parameters ensures consistent results, enhancing the overall quality of auto painting and dent repair processes. Squeeze-type resistance spot welding’s versatility and effectiveness make it a game-changer for restoration projects, ensuring that restored luxury vehicles not only look but also perform like new.

Techniques and Tools Used in the Process

The process of Squeeze-Type Resistance Spot Welding for luxury vehicle restoration involves advanced techniques and specialized tools. This precise method utilizes a concentrated high-energy electrical pulse to create a strong, narrow weld in thin metal sheets, ideal for the meticulous work required on classic or damaged vehicle bodywork. The key tool is a resistance spot welder, which generates heat through electrical resistance, allowing for controlled welding without melting the surrounding material.

This technique is particularly effective for dent repair and intricate automotive repair services, where maintaining the original aesthetics of the luxury vehicle is paramount. Specialized nozzles and adjustable settings on the welder enable technicians to precisely target weld points, minimizing heat input and ensuring a strong, lasting bond without damaging the adjacent panels or finishes. This meticulous approach is crucial for achieving perfect fusion in vehicle restoration projects, where every detail matters.

Squeeze-type resistance spot welding is a specialized technique that offers significant advantages for luxury vehicle restoration, ensuring precise and durable welds. By leveraging advanced tools and understanding the process, restorers can achieve exceptional results, preserving the vehicle’s original aesthetics while maintaining structural integrity. This innovative approach to resistance spot welding is a game-changer in the industry, providing both efficiency and quality for luxury car enthusiasts.