Core support replacement is a critical skill for automotive body shops, enabling complex repairs while maintaining structural integrity and safety. Multi-shop repair coordination combines specialized teams to handle diverse tasks, from frame straightening to panel replacement, delivering superior quality restoration experiences through efficient processes, digital tools, and structured systems, ultimately enhancing customer satisfaction and shop reputation.

In today’s competitive market, efficient core support replacement and multi-shop repair coordination are vital for maintaining product quality and customer satisfaction. This article delves into the strategic aspects of these processes, offering insights on understanding core support replacement, implementing effective multi-shop repair coordination, and streamlining core support processes for optimal efficiency. By exploring these key areas, businesses can enhance their operational resilience and competitive edge.

- Understanding Core Support Replacement: A Deep Dive

- Multi-Shop Repair Coordination: Strategies and Benefits

- Efficient Management: Streamlining Core Support Processes

Understanding Core Support Replacement: A Deep Dive

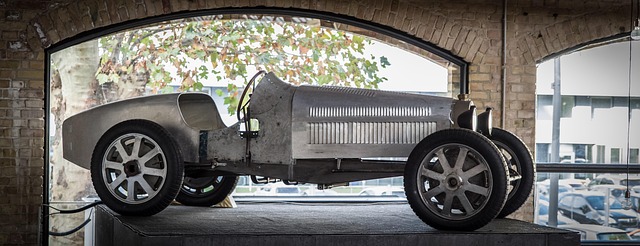

Understanding Core Support Replacement is a critical aspect of modern vehicle repair, particularly within the context of an automotive body shop. This process involves the replacement of a vehicle’s core components, which are essential for its structural integrity and safety. By specializing in core support replacement, auto body shops can significantly enhance their capabilities to handle complex repairs effectively. These core parts, often subject to severe damage or wear, play a pivotal role in maintaining the overall stability and performance of a vehicle during and after restoration.

In the realm of vehicle repair, core support replacement is not merely a technical fix but a strategic move towards ensuring long-lasting results. It requires a deep understanding of automotive engineering, precise measurement, and skilled craftsmanship. Auto body shops that master this skill can offer multi-shop coordination, connecting specialized teams for comprehensive repairs, from frame straightening to panel replacement. This coordinated approach ensures that every aspect of the vehicle’s repair is executed with precision, ultimately delivering a superior quality restoration experience.

Multi-Shop Repair Coordination: Strategies and Benefits

Multi-Shop Repair Coordination involves collaborating with different specialized shops to handle various aspects of a vehicle’s repair, especially in cases of complex or extensive damage that requires multiple skills and equipment. This strategy allows for efficient core support replacement, ensuring that each shop focuses on their area of expertise. For instance, while one center excels in precision metalwork, another might specialize in advanced electronics repairs; together, they can tackle any car bodywork challenge.

By coordinating multi-shop efforts, collision repair centers can offer faster turnaround times and higher quality work. This approach benefits both customers and businesses, as it streamlines the repair process, reduces overall costs, and ensures that every vehicle receives the best possible care. It also fosters a network of reliable service providers, enhancing the reputation of all involved parties in the car bodywork industry.

Efficient Management: Streamlining Core Support Processes

In the realm of automotive repair, efficient management is paramount, especially when dealing with complex procedures like core support replacement. Streamlining core support processes is a game-changer for workshops and garages, ensuring swift and accurate repairs. By implementing structured systems, technicians can navigate the intricate steps of replacing damaged components, such as those involved in car dent removal or mercedes benz collision repair, with enhanced precision.

This strategic approach involves every aspect from inventory management to workforce allocation. Digital tools and software can play a pivotal role by providing real-time updates on parts availability, automating order processing for car body repair, and offering step-by-step guides tailored to specific vehicle models. As a result, workshops can reduce turnaround times, minimize errors, and ultimately deliver superior customer satisfaction, solidifying their reputation in the industry.

Core support replacement and multi-shop repair coordination are essential strategies for enhancing efficiency and streamlining operations within automotive service centers. By understanding the intricacies of core support replacement and implementing coordinated repair processes, shops can significantly reduce downtime, optimize resource utilization, and ultimately provide better service to their customers. These practices are vital in today’s competitive market, where quick turnaround times and high-quality workmanship are expected.