TIG welding collision systems automate arc adjustments in panel fabrication using TIG techniques and sensor detection, enhancing precision, efficiency, and quality control for repairs in automotive and aerospace industries. They streamline processes, reduce waste, cut turnaround times, and preserve intricate designs while optimizing vehicle design through data analysis of panel behavior under impacts, ultimately elevating overall quality.

In the realm of panel fabrication, understanding when to employ TIG welding collision systems is key to enhancing efficiency and quality. This article delves into the intricate world of these systems, offering insights on their benefits in streamlining production processes. We explore diverse applications, from structural components to artistic metalwork, highlighting best practices for optimal results. By harnessing the power of TIG welding collision systems, fabricators can navigate complex projects with precision and speed.

- Understanding TIG Welding Collision Systems

- Benefits in Panel Fabrication Processes

- Applications and Best Practices

Understanding TIG Welding Collision Systems

TIG welding collision systems are specialized tools designed to enhance precision and efficiency in panel fabrication processes, particularly when dealing with delicate metal structures. These systems utilize a unique approach by combining TIG (Tungsten Inert Gas) welding techniques with advanced sensors and computer-controlled mechanisms. The primary goal is to minimize damage during the welding process, especially in tight spaces where manual control can be challenging. By detecting collisions or proximity to obstacles, these systems automatically adjust the welding arc, ensuring precise and clean welds without causing unnecessary wear or damage.

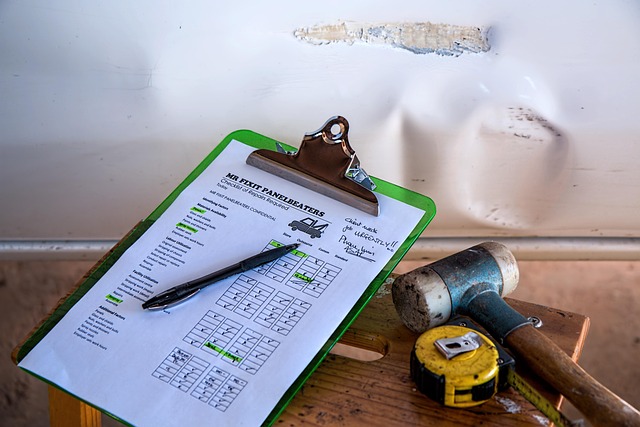

This technology is particularly valuable in industries like automotive repair, where quick and effective car dent removal or paintless dent repair techniques are sought after following minor fender benders. TIG welding collision systems offer a more controlled and nuanced approach to fabrication, allowing for the preservation of intricate designs and finishes on vehicles. This advanced method streamlines the repair process, reduces material waste, and ultimately contributes to faster turnaround times without compromising quality.

Benefits in Panel Fabrication Processes

In panel fabrication processes, integrating TIG welding collision systems offers significant advantages that streamline production and enhance quality. These advanced systems are designed to automate the collision or impact testing phase, which is crucial for ensuring structural integrity in automotive body shops and car repair services. By employing TIG (Tungsten Inert Gas) welding techniques alongside collision systems, fabricators can achieve precise and repeatable results. This automation not only accelerates production but also improves safety by minimizing manual intervention during high-energy collision simulations.

Moreover, the integration of TIG welding collision systems allows for detailed data analysis, providing insights into panel behavior under various impact scenarios. This information is invaluable for optimizing vehicle design and manufacturing processes in both auto repair services and automotive body shops. The ability to predict and mitigate potential failure points before final assembly can lead to substantial cost savings, faster turnaround times, and improved overall quality in the production of vehicles and their components.

Applications and Best Practices

TIG welding collision systems are versatile tools that find applications across various industries, from automotive to aerospace manufacturing. These advanced systems use a non-consumable tungsten electrode to create strong, precise welds, making them ideal for intricate panel fabrication tasks. In collision repair shops and auto body businesses, TIG welding is particularly valuable for repairing and restoring vehicle dent repairs and auto glass replacement, ensuring structural integrity while achieving a seamless finish.

Best practices for implementing TIG welding collision systems involve prioritizing safety first. Welders must be adequately trained to handle the equipment and the potential hazards associated with high-energy arcs. Proper ventilation is crucial to prevent the accumulation of harmful fumes, especially when working with certain metals. Additionally, maintaining clean and organized work areas helps minimize the risk of accidents and improves overall efficiency in the collision repair process, whether for vehicle dent repair or complex auto glass replacement jobs.

TIG welding collision systems offer a game-changing approach to panel fabrication, enhancing efficiency and precision. By understanding these systems and their benefits, fabricators can streamline processes, reduce waste, and achieve superior weld quality. Adopting best practices for applications across various industries ensures successful integration, making TIG welding collision systems an invaluable asset in modern fabrication techniques.