Urethane bumper parts are transforming vehicle body repairs with their superior strength, durability, and flexibility compared to traditional materials like metal or plastic. They offer competitive pricing without sacrificing quality, making them an affordable yet high-performance choice for auto body shops and consumers alike. The cost of urethane bumper parts varies based on design complexity, thickness, manufacturing process, and market demand, with intricate shapes and higher-gauge materials coming at a premium. Urethane's ability to facilitate paintless dent repair further enhances its value in automotive repairs.

“In today’s market, understanding the cost dynamics of automotive components is crucial. This article delves into the world of urethane bumper parts, exploring their distinct properties and cost comparisons with traditional materials. We analyze the factors influencing the price point of urethane bumper parts, offering a comprehensive guide for consumers and industry professionals. By examining these aspects, we aim to provide insights into why urethane bumper parts are becoming a preferred choice and their potential impact on the automotive landscape.”

- Understanding Urethane Bumper Parts and Their Unique Properties

- Cost Comparison: Urethane vs Traditional Bumper Materials

- Factors Influencing the Price of Urethane Bumper Parts

Understanding Urethane Bumper Parts and Their Unique Properties

Urethane bumper parts are a cutting-edge solution in the realm of vehicle body repair. This advanced material offers unparalleled strength and durability while maintaining exceptional flexibility, making it a game-changer for auto maintenance. Unlike traditional materials, urethane boasts excellent resistance to impact and wear, ensuring that bumper parts last longer without compromising aesthetics or structural integrity. Its unique properties make it ideal for a variety of applications in both car paint services and general auto maintenance routines.

The versatility of urethane is particularly evident when considering its ability to mimic the look and feel of original equipment while providing enhanced protection. This makes urethane bumper parts not just practical solutions but also aesthetically pleasing alternatives, especially for those looking to restore their vehicle’s beauty without a complete repaint. In terms of cost compared to other materials, urethane stands out as a competitive option, offering both high-quality performance and affordability in the market for vehicle body repair.

Cost Comparison: Urethane vs Traditional Bumper Materials

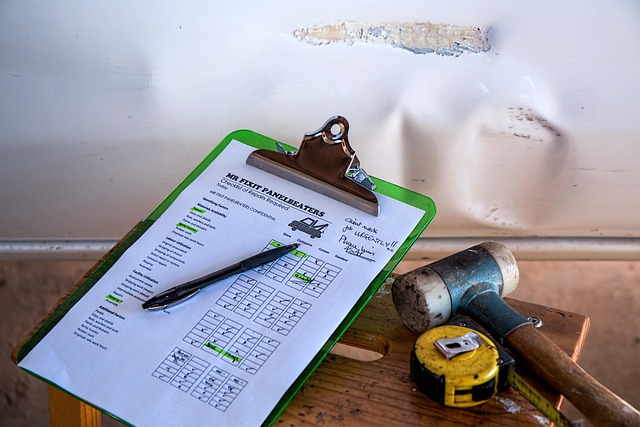

When comparing urethane bumper parts to traditional materials like metal or plastic, the former stands out for its cost-effectiveness. Urethane is a versatile and durable material that offers excellent impact resistance, making it a preferred choice for auto body shops and tire services looking to replace or repair bumpers. Its malleability allows for easier customization, reducing wastage during the manufacturing process, which in turn translates to lower production costs.

Moreover, urethane bumper parts have gained popularity due to their longevity and resistance to chipping, peeling, and cracking—common issues with plastic bumpers. In comparison to auto glass repair or even traditional auto body shop repairs, urethane provides a more affordable solution without compromising quality. This makes it an attractive option for both consumers and businesses seeking reliable, long-lasting, and cost-efficient bumper replacements.

Factors Influencing the Price of Urethane Bumper Parts

The cost of urethane bumper parts is influenced by several factors. One key consideration is the complexity of the design and shape required for a specific vehicle model. Since urethane is a versatile material, it can be molded into intricate shapes to match original equipment manufacturer (OEM) specifications, which often comes at a premium price. Additionally, the thickness and quality of the urethane used play a significant role; higher-gauge materials typically offer better durability and resistance to impact, thus commanding a higher price point.

Another crucial factor is the manufacturing process. Urethane bumper parts are usually produced through injection molding or compression molding, each with its own cost implications. Specialized machinery and skilled labor are required for precise manufacturing, contributing to the overall pricing. Moreover, the market demand for urethane bumper parts, as well as competition among manufacturers, can also affect prices. In an automotive repair or collision center setting, choosing urethane parts might be preferred for their ability to facilitate paintless dent repair, which further underscores the material’s value and cost considerations.

When considering the cost of urethane bumper parts, it’s clear that while they may have a higher upfront price point compared to traditional materials, their unique properties offer significant long-term benefits. Urethane’s durability, impact resistance, and flexibility make it a superior choice for many applications, ensuring better performance and reduced replacement needs over time. While the initial investment might be slightly higher, the value proposition of urethane bumper parts is undeniable for those seeking reliable, high-quality automotive solutions.