Plasma cutting collision repair is a game-changer for professionals, offering precise and efficient cuts crucial for accurate frame straightening and bumper repairs. The right plasma cutter, chosen based on work complexity, desired finish, and efficiency needs, ensures top-quality results. Meticulous surface preparation using degreasers, scrubbers, wire brushes, and fine-grit sandpaper is paramount for accurate cuts and repair longevity, especially in demanding brands like Mercedes Benz.

Plasma cutting has emerged as a game-changer in collision repair, offering precise and efficient metal fabrication. This advanced technique demands specialized equipment and meticulous preparation for optimal results. In this article, we provide expert tips to master plasma cutting collision repair. From selecting the right plasma cutter tailored to your needs to preparing surfaces optimally before cutting, these strategies will help you achieve accurate, high-quality repairs.

- Mastering Plasma Cutting Techniques for Precise Repairs

- Choosing the Right Plasma Cutter for Collision Damage

- Efficient Surface Preparation Before Plasma Cutting Collision Repair

Mastering Plasma Cutting Techniques for Precise Repairs

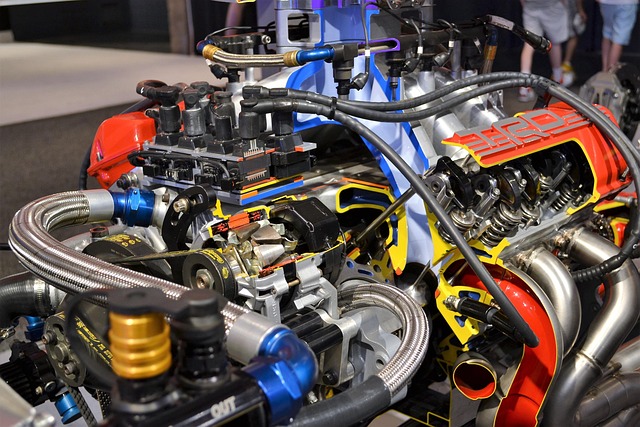

Mastering plasma cutting techniques is a game-changer for anyone involved in collision repair. This advanced technology allows for precise and efficient cutting, which is essential for achieving accurate measurements when straightening car frames or repairing bumpers. By understanding different plasma cutting methods, professionals can select the optimal approach based on the damage, ensuring minimal waste and maximizing material retention.

For example, in car restoration projects, where intricate and detailed work is often required, a precise plasma cutter can navigate complex shapes and curves with ease. This level of control enables restorers to preserve the original aesthetics while making necessary repairs. Whether it’s frame straightening or bumper repair, mastering plasma cutting collision repair techniques opens up new possibilities for achieving high-quality, professional results.

Choosing the Right Plasma Cutter for Collision Damage

When it comes to plasma cutting collision repair, selecting the appropriate tool is paramount. The right plasma cutter for collision damage should be chosen based on several factors including the type and severity of the automotive body work required, the desired finish, and the efficiency needed to complete repairs promptly.

For instance, while a basic plasma cutter might suffice for minor car scratch repairs, more complex collision damage often necessitates a machine with higher power output and precision control. Professional automotive repair services thus favor advanced plasma cutters that offer greater versatility and accuracy, enabling them to handle a wide range of tasks from metal cutting to weld preparation in the most demanding automotive body work scenarios.

Efficient Surface Preparation Before Plasma Cutting Collision Repair

Before plunging into plasma cutting collision repair, ensure your surface is thoroughly prepared for optimal results. This involves meticulous cleaning to remove any grease, dirt, or debris that could hinder the precision and efficiency of the plasma cutting process. A degreaser designed for automotive applications can be used to strip away contaminants, leaving a clean slate for repair work.

Scraping and sanding are crucial subsequent steps in surface preparation. Use a metal scrubber or wire brush to aggressively remove any remaining debris, followed by fine-grit sandpaper to smoothen the area and create a rough texture that enhances adhesion. This meticulous preparation is paramount not only for achieving accurate cuts but also for guaranteeing the longevity of the repair, particularly in demanding sectors like Mercedes Benz repair where vehicle bodywork demands meticulous attention to detail.

Plasma cutting collision repair is a precise and efficient method that, when combined with the right techniques and tools, can significantly enhance vehicle restoration efforts. By mastering plasma cutting techniques, selecting the appropriate cutter for your needs, and ensuring thorough surface preparation, you’ll achieve accurate and quality repairs, making plasma cutting a valuable asset in the automotive body shop.