The Tesla measure system is a groundbreaking tech solution for auto body services, offering precise damage assessment, repair optimization, and cost reduction. It enhances efficiency, accuracy, and quality across various applications, from collision centers to classic car restoration, by eliminating manual errors, streamlining operations, and providing detailed measurements for informed decision-making.

Discover the transformative power of the Tesla Measure System, a groundbreaking technology redefining precision and efficiency across industries. This innovative tool goes beyond mere measurement, offering unparalleled accuracy and versatility. From design studios to construction sites, the Tesla Measure System streamlines workflows, enhances productivity, and unlocks new possibilities. Explore real-world applications, uncover its impact on various sectors, and understand why this system is a game-changer in precision measurements.

- Unlocking Precision: Tesla Measure System in Action

- Revolutionizing Industries: Real-World Applications

- From Design to Construction: Streamlining Processes

Unlocking Precision: Tesla Measure System in Action

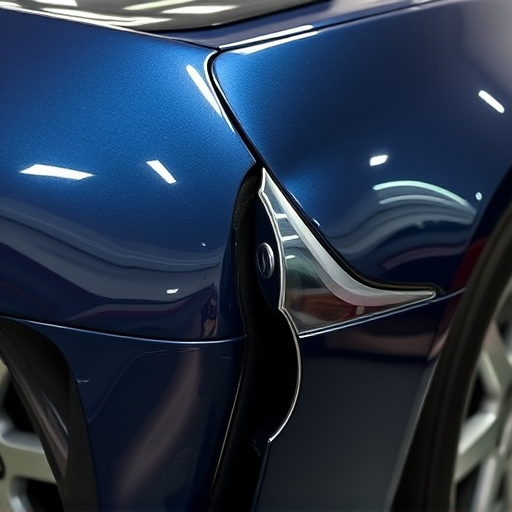

The Tesla Measure System is a game-changer when it comes to precision and accuracy in various real-world applications. This advanced technology is designed to pinpoint exact measurements, ensuring every detail is accounted for. For instance, in the realm of auto repairs, it plays a pivotal role. Whether it’s a simple bumper repair or a more intricate task like auto glass replacement, the Tesla Measure System enhances efficiency and quality. Mechanics can now accurately gauge impact damage, measure replacement parts with precision, and ensure perfect alignment during repairs, such as scratch repair.

This system is not limited to vehicles; its applications are vast. From construction projects requiring meticulous measurements to ensuring the perfect fit for custom furniture, the Tesla Measure System offers unparalleled accuracy. By providing detailed, precise data, it enables professionals to make informed decisions, ultimately saving time and resources. This technology truly revolutionizes how we approach tasks that demand a high level of exactness, leaving no room for error in even the most complex scenarios, including auto body repairs like bumper and scratch repair.

Revolutionizing Industries: Real-World Applications

The Tesla measure system is transforming various industries by bringing precision and efficiency to tasks that were once time-consuming and error-prone. One notable area where this technology is making waves is in auto body services and collision centers. With the help of the Tesla measure system, professionals in these fields can now swiftly and accurately assess damage, streamline repair processes, and reduce overall costs. This advanced tool enables them to capture detailed measurements of vehicles, ensuring precise repairs that match the original vehicle specifications.

Beyond collision centers, the Tesla measure system is finding applications in vehicle body shops as well. Its ability to provide comprehensive data on vehicle bodies allows for more effective planning and execution of repairs, leading to faster turnaround times and higher customer satisfaction. By leveraging this technology, auto body shops can enhance their services, compete effectively, and meet the demands of a market that values speed, accuracy, and quality in every aspect of vehicle maintenance and repair.

From Design to Construction: Streamlining Processes

The Tesla measure system is a game-changer in both design and construction processes, offering precision and efficiency that was once unimaginable. It streamlines operations from the initial planning stages to final assembly, eliminating tedious manual measurements and errors commonly associated with traditional methods. This digital solution allows car repair shops and classic car restoration specialists to work smarter, not harder.

By implementing the Tesla measure system, professionals in the automotive industry can achieve precise frame straightening, ensuring that every curve and angle meets exacting standards. This level of accuracy is critical for both aesthetic appeal and structural integrity, especially when dealing with vintage vehicles where parts are often custom-made or hard to come by. The system’s ability to capture detailed measurements enables efficient workflow management, reducing the time typically spent on laborious manual tasks, thereby increasing productivity in car repair shops.

The Tesla Measure System has proven its worth across various industries, offering unparalleled precision and efficiency. By leveraging this innovative technology, professionals can streamline design and construction processes, ensuring projects are completed with exacting accuracy. From engineering marvels to everyday structures, the real-world applications of the Tesla Measure System underscore its potential to revolutionize how we build and shape our world.