Modern vehicles' complex geometries challenge primer surfacer application, requiring automotive shops to adapt techniques with advanced tools and training. Skilled technicians ensure even coverage for aesthetics and structural integrity, controlling thickness precisely to avoid overspray and rust. Collision repair services face stringent regulations, investing in best practices for quality and compliance in primer surfacer handling.

In modern vehicle design, the intricate geometry of cars poses unique challenges for primer surfacer application. This article delves into the complexities of achieving precise coverage and consistent thickness on increasingly elaborate car surfaces. We explore how manufacturers must adapt to stringent environmental and safety standards while ensuring optimal paint adherence and long-lasting finishes. Understanding these issues is crucial for professionals aiming to master the art of primer surfacer application in today’s automotive landscape.

- Understanding Complex Modern Vehicle Geometries

- Challenges in Achieving Consistent Coverage and Thickness

- Adapting to Strict Environmental and Safety Standards

Understanding Complex Modern Vehicle Geometries

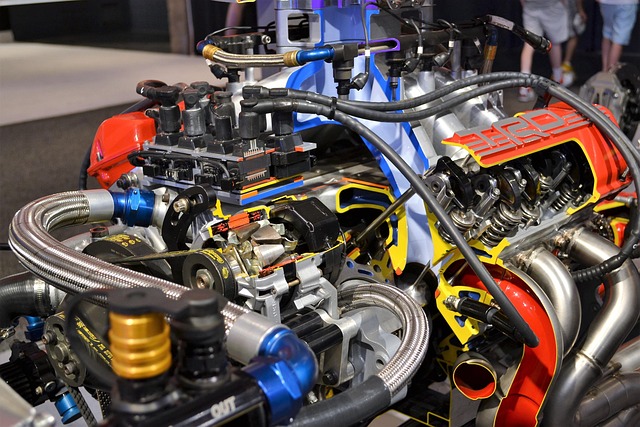

Modern vehicle designs present unique challenges for primer surfacer application due to their complex geometries. Unlike simpler shapes found in older models, contemporary cars and trucks often feature intricate curves, contoured panels, and integrated components that demand precise handling during the prep stage. This complexity necessitates a thorough understanding of the vehicle’s anatomy to ensure even coverage and minimize issues like overspray or missed spots.

Automotive repair shops specializing in auto painting and dent repair must adapt their techniques accordingly. They employ advanced tools and training methods to navigate these complex geometries, ensuring that every nook and cranny is prepared for the subsequent coating stages. This meticulous approach not only guarantees superior aesthetics but also plays a crucial role in protecting the vehicle’s structural integrity and longevity.

Challenges in Achieving Consistent Coverage and Thickness

Achieving consistent coverage and thickness during primer surfacer application is a significant challenge in modern vehicle designs. With complex shapes, intricate curves, and tight spaces, ensuring every surface receives an even coat can be difficult. Even minor variations in application can lead to visible imperfections, affecting both aesthetics and structural integrity.

This challenge is further compounded by the need for precise thickness control. Overapplication may result in excess material that needs to be meticulously sanded down, adding time and potential damage risk. Underapplication, on the other hand, leaves areas vulnerable to rust and paint failure. Skilled technicians employ various techniques, such as specialized tools and careful surface preparation, to navigate these complexities. Fleet repair services and collision centers continually strive for consistent application methods to streamline operations and deliver high-quality vehicle dent repair outcomes.

Adapting to Strict Environmental and Safety Standards

In modern vehicle designs, adapting to strict environmental and safety standards poses significant challenges for primer surfacer application. As regulations tighten, automotive body shops must adhere to stringent emission controls while ensuring the structural integrity of repairs, particularly in complex car body restoration processes. This requires precise handling of primer surfacers to meet not only regulatory but also quality standards.

Collision repair services, a critical component of the automotive industry, are at the forefront of these challenges. With advancements in materials and construction techniques, modern vehicles involve intricate paneling and finishing requirements. Effective primer surfacer application becomes even more crucial to prevent rust and ensure long-lasting durability. Shops must invest in training and technology to meet these demands, aligning their processes with the latest industry best practices.

Modern vehicle designs present unique challenges for primer surfacer application, from complex geometries to stringent environmental and safety standards. Navigating these hurdles requires a deep understanding of both the vehicle’s intricate forms and the need for consistent, uniform coverage and thickness. Adhering to these demanding criteria ensures not only optimal paint adhesion but also contributes to enhanced vehicle durability and safety, highlighting the critical role of primer surfacer application in today’s automotive landscape.