Computerized frame measurement is revolutionizing the automotive industry, especially for hybrid and electric vehicles (EVs), by accurately assessing frame integrity using advanced sensors and software. This technology surpasses manual measurements in detecting subtle deformities, ensuring precise straightening for enhanced safety and handling standards. It also aids in effective repairs and minimizes car scratch repair impact by providing holistic frame condition views, boosting vehicle performance and longevity. As the demand for EVs and hybrids grows, so does the need for advanced frame measurement techniques, streamlining processes, improving safety, reducing costs, and catering to unique vehicle needs.

In the rapidly evolving automotive landscape, Computerized Frame Measurement (CFM) is revolutionizing the way hybrid and electric vehicle (EV) models are designed, manufactured, and maintained. This advanced technology offers unprecedented precision and efficiency in assessing structural integrity, enabling engineers to optimize performance, safety, and durability. By streamlining processes and reducing manual errors, CFM is a game-changer for the industry, paving the way for future innovations in EV and hybrid framework assessment.

- Understanding Computerized Frame Measurement: The Basics and Benefits for Hybrid and Electric Vehicles

- Implementation of Computerized Frame Measurement: Tools, Technologies, and Processes

- Advanced Applications and Future Trends in EV and Hybrid Framework Assessment

Understanding Computerized Frame Measurement: The Basics and Benefits for Hybrid and Electric Vehicles

Computerized frame measurement is a cutting-edge technology revolutionizing the automotive industry, especially for hybrid and electric vehicles (EVs). This advanced process involves using specialized software and sensors to accurately assess and document the structural integrity of a vehicle’s frame. By providing detailed data on frame geometry, alignment, and any existing damage, computerized frame measurement offers numerous advantages in the repair and maintenance of these modern automobiles.

One of its key benefits is ensuring precise frame straightening, which is crucial for maintaining optimal handling and safety standards. Unlike traditional manual measurements, this technology enables auto frame repair specialists to identify even subtle deformities or misalignments, facilitating more effective repairs. Moreover, it aids in minimizing the impact of car scratch repair by providing a comprehensive view of the frame’s condition, allowing technicians to focus on necessary repairs, enhancing overall vehicle performance and longevity.

Implementation of Computerized Frame Measurement: Tools, Technologies, and Processes

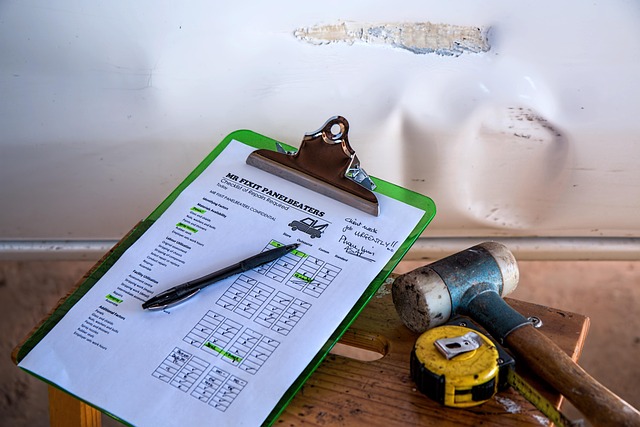

The implementation of computerized frame measurement is a pivotal step in the evolution of hybrid and electric vehicle (EV) manufacturing and repair processes. This advanced technology leverages sophisticated tools and technologies to accurately assess and document the structural integrity of a vehicle’s frame, ensuring precision in both new car production and post-collision repair scenarios.

State-of-the-art sensors, laser scanners, and 3D imaging systems play a crucial role in this process, enabling detailed digital mapping of the frame. These tools not only capture dimensions but also identify any deformities or discrepancies caused by car collisions or other impacts. The data collected is then processed using specialized software that analyzes the information to generate comprehensive reports, facilitating informed decision-making at collision repair centers and auto dent repair facilities. This technology ensures that repairs are carried out with meticulous accuracy, restoring not just the physical structure but also the original aesthetic appeal of hybrid and EV models.

Advanced Applications and Future Trends in EV and Hybrid Framework Assessment

The future of electric vehicles (EVs) and hybrid models is bright, and with it comes an increased demand for precise and efficient frame measurement techniques. Computerized frame measurement has emerged as a game-changer in this domain, offering advanced applications that were previously unattainable. These technologies are revolutionizing auto repair services, particularly in the realm of car collision repair, by providing detailed insights into vehicle structures.

As the market for EVs and hybrids continues to grow, so does the need for specialized tools to handle their unique challenges. Future trends suggest a greater emphasis on non-destructive testing methods, real-time data analysis, and improved 3D scanning capabilities. These advancements will enable car repair services to streamline processes, enhance safety, and reduce costs associated with traditional frame measurement techniques. By embracing these innovations, the industry can better cater to the specialized needs of EV and hybrid vehicles, ensuring optimal performance and longevity.

Computerized frame measurement is revolutionizing the way hybrid and electric vehicle (EV) models are designed, assessed, and improved. By offering precise data and streamlined processes, this technology enhances efficiency, safety, and sustainability in the automotive industry. As advancements continue to unfold, we can expect even more sophisticated applications that further optimize EV and hybrid frameworks, shaping a greener and smarter future for transportation.