Radiator support replacements in commercial vehicles require careful assessment for damage, especially after minor incidents. Complete replacement is often recommended to maintain structural integrity and prevent future issues. Efficient replacement processes involve inspecting, removing damaged parts, installing new supports accurately, testing, and addressing noise or leaks. Fleet managers should prioritize proactive scheduling, regular inspections, and specialized training to minimize downtime and maximize operational continuity during radiator support replacements.

Looking to optimize your fleet’s performance and efficiency? Effective radiator support replacement is a crucial task for commercial vehicles, ensuring optimal cooling systems and minimizing downtime. This comprehensive guide delves into the intricacies of understanding your vehicle’s radiator support structure, offering step-by-step replacement tips for seamless operations. Explore common challenges faced by fleet managers and discover best practices to streamline maintenance processes. Master the art of radiator support replacement for enhanced fleet reliability.

- Understanding Radiator Support Structure in Commercial Vehicles

- Steps for Efficient Radiator Support Replacement

- Common Challenges and Best Practices for Fleet Managers

Understanding Radiator Support Structure in Commercial Vehicles

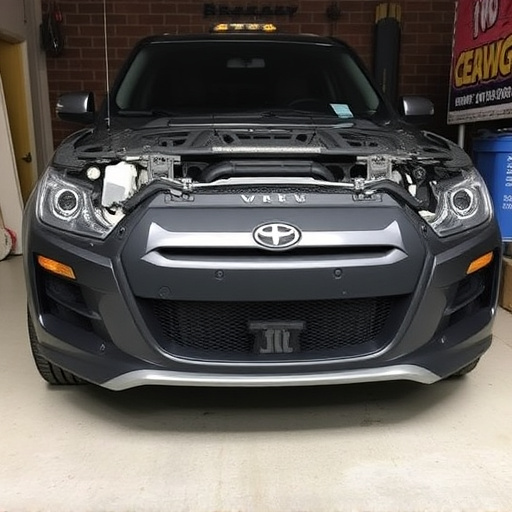

Commercial vehicles, from trucks to vans, have distinct structural requirements compared to their passenger car counterparts. One critical component that often gets overlooked until it fails is the radiator support structure. This robust framework not only secures the radiator but also bears the brunt of frontal impacts and road debris during a fender bender or more severe accidents. Understanding this system’s design and its role in vehicle safety is paramount when considering a radiator support replacement, especially for fleet managers tasked with maintaining a reliable and safe commercial fleet.

When it comes to replacing a damaged or worn-out radiator support, professionals recommend a thorough assessment of the existing structure. In some cases, particularly after a car dent repair or minor fender bender, the damage might be localized. However, due to the structural importance of the radiator support, complete replacement is often advised to ensure the integrity of the vehicle’s frame and prevent future complications. This process involves more than just swapping out the part; it requires knowledge of the specific vehicle model and the potential for hidden damage that could impact other components, especially in tight spaces where a car dent repair might have been performed earlier.

Steps for Efficient Radiator Support Replacement

When conducting a radiator support replacement on fleet or commercial vehicles, efficiency is key to minimize downtime and maintenance costs. Begin by thoroughly inspecting the existing structure for any signs of damage or wear. This involves checking for cracks, rust, or loose components that could impact the new support’s stability and effectiveness. Once identified, safely remove any damaged parts using appropriate tools tailored to the vehicle’s make and model.

Next, acquire a high-quality radiator support replacement designed specifically for your vehicle’s requirements. Ensure it aligns with the manufacturer’s specifications for fitment and performance. With the new support in hand, carefully install it, securing all bolts and brackets as per the vehicle’s service manual. Verify the proper alignment and positioning of the radiator and other associated components to guarantee optimal cooling efficiency. Finally, test drive the vehicle to ensure seamless operation and address any unusual noises or leaks promptly, considering potential implications for auto glass repair or collision repair shop visits if issues arise during driving.

Common Challenges and Best Practices for Fleet Managers

Fleet managers often face unique challenges when it comes to vehicle maintenance, especially with regard to radiator support replacement. One of the primary difficulties is ensuring timely repairs without disrupting daily operations. With commercial vehicles, down time can significantly impact business continuity. Therefore, efficient and effective radiator support replacement processes are paramount.

Best practices for fleet managers include developing a proactive maintenance schedule, regularly inspecting radiators for signs of wear or damage, and keeping a well-stocked inventory of replacement parts. Utilizing specialized car repair services that offer quick turnaround times for radiator support replacement can also mitigate disruptions. Additionally, regular training sessions for the maintenance team on collision repair techniques specific to radiators can enhance the overall efficiency of repairs.

When it comes to maintaining fleet and commercial vehicles, efficient radiator support replacement is a crucial aspect of keeping your vehicles running smoothly. By understanding the unique structure of commercial vehicle radiators and adopting best practices for replacement, fleet managers can significantly reduce downtime and improve overall vehicle performance. Embracing these tips ensures a structured approach to radiator support replacement, ultimately contributing to a more robust and reliable fleet.