Environmental factors like moisture, temperature, air pollution, and salt water significantly impact corrosion on vehicles, requiring targeted corrosion prevention strategies in collision repair. Professionals use protective coatings, underbody sealing, and specialized materials to mitigate rust formation. Coastal areas necessitate additional measures due to high humidity and salt content. In harsh environments, a comprehensive approach involving worker protection, waste management, and advanced coatings is crucial for infrastructure and vehicle longevity. Integrating corrosion prevention into collision repair services enhances vehicle lifespan and cost-effectiveness by protecting against future damage in regions with fluctuating temperatures and rainfall.

Environmental conditions play a pivotal role in shaping corrosion prevention strategies. This article delves into the intricate relationship between ecological factors and metal degradation, offering insights that can significantly enhance protective measures. We explore how varying environments, from humid climates to corrosive atmospheres, demand tailored approaches.

Through case studies, we showcase successful techniques that have withstood the test of time in challenging settings, providing a comprehensive guide for professionals seeking to safeguard their assets against corrosion’s detrimental collision.

- Understanding the Impact of Environmental Factors on Corrosion

- Strategies to Mitigate and Prevent Corrosion in Different Conditions

- Case Studies: Successful Corrosion Prevention Techniques in Challenging Environments

Understanding the Impact of Environmental Factors on Corrosion

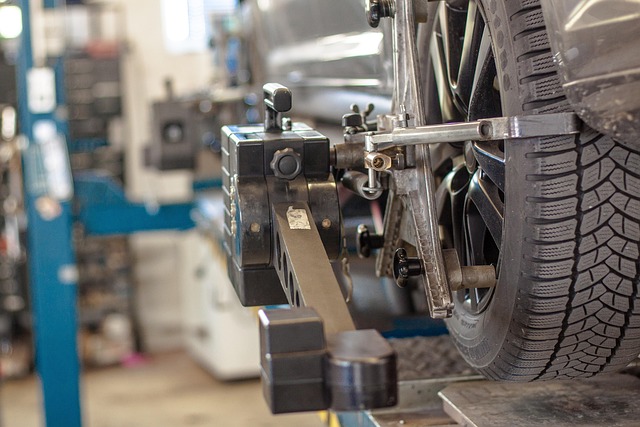

Environmental conditions play a pivotal role in shaping corrosion prevention strategies, especially in industries like automotive collision repair and vehicle dent repair. Understanding how various factors impact metal surfaces is essential to developing effective protection methods. Moisture, temperature fluctuations, and air pollution are significant contributors to corrosion, as they create the perfect environment for rust formation. For instance, salt water, often encountered in coastal regions, can accelerate corrosion, making it a formidable challenge for automotive body shops dealing with vehicle dent repair after coastal accidents.

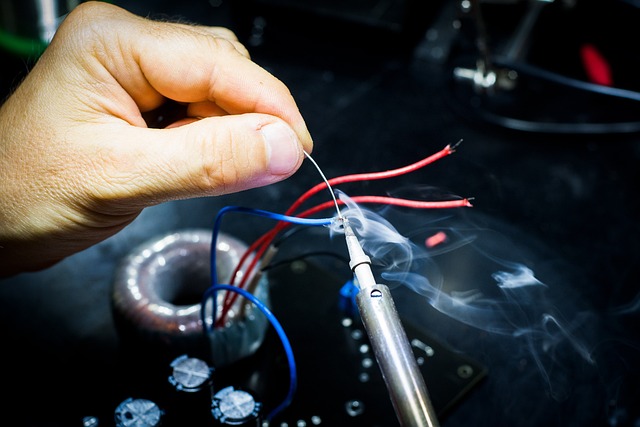

The complexity of this issue is further highlighted by the diverse range of materials used in modern vehicles. Different metals have varying corrosion resistance properties, and their interaction with environmental elements can lead to complex chemical reactions. This knowledge allows professionals in the automotive industry to employ targeted corrosion prevention techniques, such as protective coatings and underbody sealing, to safeguard against potential corrosion after an automotive collision repair, ensuring the longevity of vehicle structures.

Strategies to Mitigate and Prevent Corrosion in Different Conditions

Corrosion prevention strategies significantly vary depending on the environmental conditions a structure or material is exposed to. In coastal areas with high humidity and salt content in the air, special protective coatings are essential to prevent corrosion. These coatings create a barrier that repels moisture and blocks the penetration of corrosive substances, ensuring longevity for structures like bridges, ships, and even buildings. Regular maintenance and inspections are crucial, allowing for prompt treatment of any signs of corrosion before it spreads.

For metallic objects in industrial settings or vehicles operating in harsh terrains, preventing collision with corrosive elements requires a multi-faceted approach. This involves using protective gear such as gloves, masks, and suits to shield workers from direct contact with corrosives during auto body repair or car paint repair processes. Additionally, implementing proper waste management systems and utilizing specialized materials for auto body restoration can drastically minimize exposure to corrosive substances, thereby enhancing corrosion prevention efforts.

Case Studies: Successful Corrosion Prevention Techniques in Challenging Environments

In challenging environments characterized by extreme temperatures, high humidity, and corrosive elements, effective corrosion prevention techniques have proven to be game-changers in industries such as automotive. Case studies from around the globe highlight successful implementations that have prolonged the lifespan of critical infrastructure and vehicles. For instance, coastal regions facing constant exposure to salt water and moisture have adopted advanced coating technologies, incorporating rust-inhibiting additives into vehicle paint repair processes. This simple yet powerful approach has significantly reduced corrosion rates on cars and trucks, ensuring their structural integrity even in harsh conditions.

Another notable example involves collision repair services that have integrated corrosion prevention as a core practice. After a car collision, thorough cleaning and pre-treatment of damaged panels before application of new paint or materials are essential. These processes involve removing old, corroded layers and applying protective coatings that act as a barrier against future corrosion, especially in regions with frequent rainfall and varying temperature cycles. Such proactive measures not only enhance the longevity of vehicles but also contribute to cost-effective collision repair services by mitigating long-term damage.

Environmental conditions play a pivotal role in shaping effective corrosion prevention strategies. By understanding how factors like humidity, temperature, and chemical exposure impact materials, we can deploy tailored mitigation techniques. From innovative coatings and protective barriers to regular maintenance and material selection, the article has explored diverse approaches. Case studies have demonstrated successful implementations in challenging environments, highlighting the importance of adaptability and expertise in collision prevention. As we navigate a world with ever-changing climates and industrial landscapes, continuing research and adoption of these strategies are essential to safeguard infrastructure and assets.