OEM standards are key to structural safety verification in the automotive industry, ensuring every component meets top safety benchmarks. This rigorous process includes testing, simulation, and documentation for crashworthiness, fatigue resistance, and durability. Challenges include modern vehicle complexity and faster turnaround times. Advanced technologies and collaborative standards streamline processes, enhancing accuracy in complex structures like frames, crucial for auto body shops and Mercedes Benz repair centers.

“In the realm of structural integrity, Original Equipment Manufacturer (OEM) standards act as a cornerstone for ensuring safety. This article delves into the intricate relationship between OEM standards and structural safety verification procedures. We explore how these standards provide a comprehensive framework for evaluating complex structures, addressing unique challenges along the way. By understanding the role of OEM guidelines, professionals can enhance their approach to structural safety verification, leading to more robust and secure designs.”

- Understanding OEM Standards: A Foundation for Safety

- Structural Safety Verification: Processes and Challenges

- Impact of OEM Standards on Verifying Complex Structures

Understanding OEM Standards: A Foundation for Safety

Understanding OEM Standards: A Foundation for Safety

OEM (Original Equipment Manufacturer) standards serve as a cornerstone in the realm of structural safety verification procedures. These stringent guidelines are meticulously crafted to ensure that every component, from car bodywork to auto glass repair, meets the highest safety benchmarks. Auto body shops and manufacturers alike adhere to these standards, fostering a culture of quality and reliability.

By implementing OEM standards, the automotive industry has revolutionized safety measures, making vehicles more robust and prepared to withstand various conditions. This meticulous approach extends beyond aesthetics; it encompasses structural integrity, ensuring that every part plays its role in protecting occupants during unexpected events. Consequently, understanding and adhering to these standards is paramount for maintaining optimal vehicle performance and passenger safety across the board, be it in a top-tier auto body shop or during routine maintenance.

Structural Safety Verification: Processes and Challenges

Structural Safety Verification is a critical process that ensures vehicles, especially those undergoing repairs or reconditioning like those in a car body shop providing car paint services, meet stringent safety standards. It involves a multi-faceted approach combining rigorous testing, advanced simulation, and meticulous documentation to validate the structural integrity of various components. This includes checking key aspects such as crashworthiness, fatigue resistance, and overall durability, ensuring they can withstand real-world conditions and protect occupants in unforeseen events.

Despite its importance, structural safety verification faces several challenges. These include keeping pace with evolving design complexities, particularly in modern vehicles with sophisticated materials and advanced engineering. Additionally, the need for faster turnaround times without compromising accuracy adds pressure on testing facilities and engineers. Effective solutions often involve leveraging advanced technologies like computer-aided engineering (CAE) tools and collaborative industry standards to streamline processes and enhance accuracy during vehicle repair and car paint services, ultimately contributing to safer operational environments.

Impact of OEM Standards on Verifying Complex Structures

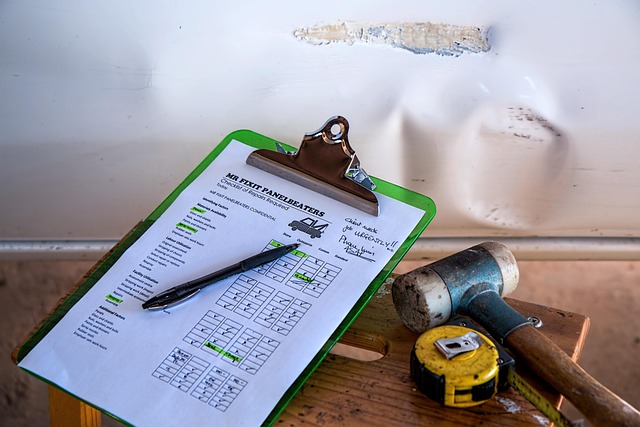

The impact of OEM (Original Equipment Manufacturer) standards on structural safety verification procedures is profound, especially for complex structures within automotive manufacturing. These stringent standards serve as a benchmark for quality and safety, ensuring that every component meets or exceeds industry-recognized criteria. When it comes to verifying the integrity of vehicle frames, for instance, OEM guidelines provide a comprehensive framework for assessing both visual and functional aspects. This involves meticulous inspections, advanced diagnostic tools, and precise measurements to detect even minute deformations or discrepancies.

For auto collision centers and dedicated Mercedes Benz repair shops, adhering to OEM standards is not just a requirement but a testament to their expertise. The process of frame straightening, a critical aspect of structural safety verification, demands precision and knowledge of the vehicle’s original design. By following these guidelines, technicians can effectively restore damaged frames to their pre-accident condition, maintaining the overall structural integrity of the vehicle. This meticulous attention to detail not only guarantees customer satisfaction but also fosters public trust in the automotive repair industry.

OEM standards play a pivotal role in enhancing the structural safety verification processes, particularly for complex structures. By establishing comprehensive guidelines and criteria, these standards ensure that every component undergoes rigorous testing and evaluation, thereby upholding the highest safety levels. Incorporating OEM best practices into structural design and analysis facilitates more efficient and reliable verification procedures, ultimately contributing to safer products and enhanced public confidence in manufacturing industries. This article has highlighted the significance of OEM standards, offering valuable insights for professionals navigating the complexities of structural safety verification.