Spot Weld Bonding Repair is a specialized auto body technique addressing compromised spot welds due to rust, accident damage, or wear and tear. It involves removing damaged welds, preparing surfaces, and applying high-quality bonding agents to restore structural integrity. This game-changer enhances structural strength in corrosion-prone areas, ensuring vehicles return to optimal condition. The process begins with inspection, preparation, application of bonding agents, precision welding, and cooling. Suitable for collision repair centers, it offers a faster, cost-effective solution, contributing to vehicle bodies' longevity.

Spot weld bonding repair is a specialized technique revolutionizing auto body work. It involves seamlessly re-attaching detached metal panels, ensuring structural integrity and aesthetic precision. This non-invasive method uses advanced welding technology to fuse damaged areas without altering the original vehicle design. By understanding the basics of spot weld bonding repair, we can appreciate its benefits in the automotive industry, where it offers a durable, cost-effective solution for various applications, from collision repair to custom fabrication.

- Understanding Spot Weld Bonding Repair: The Basics

- How Spot Weld Bonding Repair Is Performed in Auto Body Work

- Benefits and Applications of Spot Weld Bonding Repair in Automotive Industry

Understanding Spot Weld Bonding Repair: The Basics

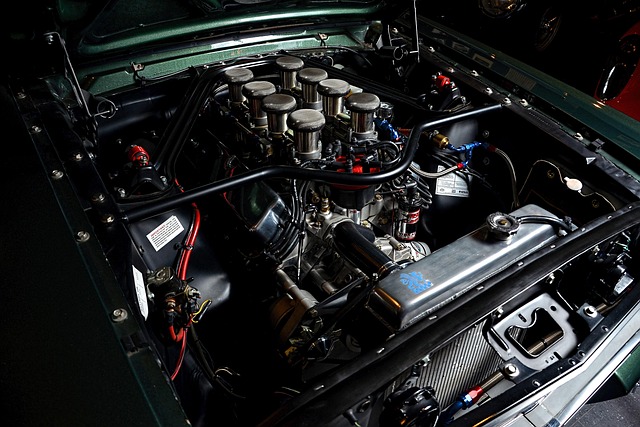

Spot Weld Bonding Repair is a specialized technique within auto body work, focusing on reinforcing and restoring weak or damaged spot welds. Spot welds are small, localized welds used to join metal panels in vehicles during manufacturing. Over time, these welds can become compromised due to various factors like rust, accident damage, or normal wear and tear.

The process involves carefully removing the affected welds, preparing the surfaces, and then applying a high-quality bonding agent to create a strong, durable bond that matches the vehicle’s structural integrity. This repair method is crucial for maintaining the safety and structural stability of vehicles, especially in areas prone to corrosion or previous damage. It’s a game-changer in car dent repair and car body repair scenarios, ensuring that the vehicle returns to its optimal condition with enhanced structural strength.

How Spot Weld Bonding Repair Is Performed in Auto Body Work

Spot weld bonding repair is a specialized technique used in auto body work to reinforce and restore weak or damaged spot welds. The process begins with careful inspection to identify the extent of the damage, which could range from rust formation to loose or missing welds. Once identified, the affected area is prepared by removing any debris, corrosion, or loose material using specialized tools.

The actual repair involves applying a high-quality bonding agent specifically designed for automotive applications. This agent creates a strong bond between the existing metal and a filler piece, which is then welded into place to strengthen the spot weld. Body shop technicians use precision equipment to ensure accurate alignment and secure the new weld, allowing it to cool and set properly. This method not only enhances structural integrity but also offers a cost-effective solution for repairing minor damage in both collision repair centers and auto maintenance facilities, contributing to the longevity of vehicle bodies.

Benefits and Applications of Spot Weld Bonding Repair in Automotive Industry

Spot Weld Bonding Repair offers numerous advantages for the automotive industry, revolutionizing how vehicle body shops approach auto dent repair and auto body restoration. This advanced technique is particularly useful for repairing and reinforcing spot welds, which are critical in maintaining a vehicle’s structural integrity. By focusing on these specific bonds, it becomes possible to achieve stronger, more durable repairs without the need for extensive metalwork or replacement parts.

In a bustling vehicle body shop, where efficiency and precision are key, spot weld bonding repair stands out as a game-changer. It allows technicians to quickly identify and address weak spots in a car’s body, ensuring that every repair is both effective and cost-efficient. This method also reduces the time required for auto body restoration, enabling shops to accommodate more vehicles and meet growing customer demands. Whether it’s a minor dent or a more complex structural issue, spot weld bonding provides a reliable solution, enhancing the overall quality of auto dent repair services.

Spot weld bonding repair is a pivotal technique in auto body work, offering both structural integrity and aesthetic enhancement. By understanding the basics, mastering performance techniques, and recognizing its diverse applications, professionals can deliver high-quality repairs that are robust and virtually invisible. This specialized skill set not only benefits traditional auto body shops but also contributes to the advanced restoration and customization of vehicles across the automotive industry.