Frame damage assessment is a critical step in accurately estimating and transparently presenting frame repair costs for vehicles involved in accidents or collisions. Skilled technicians, utilizing advanced digital tools like 3D imaging and specialized software, meticulously examine structural integrity, identify damaged components, and measure deformities to tailor precise cost estimates for Mercedes Benz repairs or any other vehicle. This digital approach streamlines processes, enhances transparency, fosters trust, and improves efficiency in auto body shops by following best practices such as updating material price databases, integrating labor rates specific to each shop, regularly calibrating measuring devices, and training staff on the latest digital tools.

In the realm of automotive restoration, accurately estimating frame repair costs is paramount. Traditional methods often rely on experience, leading to varied and sometimes imprecise outcomes. However, digital tools have emerged as game-changers, revolutionizing how mechanics assess and quote frame repair costs. This article explores the significance of digital technology in this process, delving into damage assessment techniques, cost estimation software, and best practices that ensure precise budgeting for restoration projects, ultimately streamlining the entire repair experience.

- Understanding Frame Damage Assessment

- Digital Tools for Accurate Cost Estimation

- Benefits and Best Practices for Using Digital Technology in Frame Repair Costing

Understanding Frame Damage Assessment

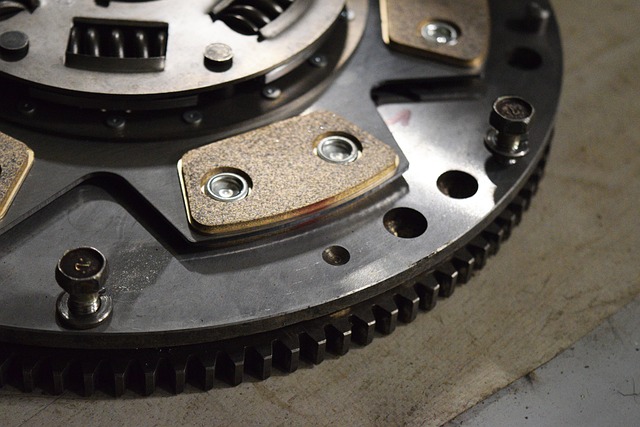

Frame damage assessment is a critical step in accurately estimating the frame repair cost for any vehicle involved in an accident or collision. This process involves meticulous examination of the vehicle’s structural integrity, identifying components that have been damaged, bent, or completely destroyed. Skilled technicians use specialized tools to measure and analyze these damages, ensuring every detail is accounted for in the final cost estimate.

In a vehicle body shop offering collision repair services, assessing frame damage requires both technical expertise and experience. Technicians utilize advanced digital tools designed to pinpoint precise measurements of deformities and misalignments. These tools help them calculate the extent of required repairs, from straightening bent panels to replacing damaged or missing parts. By integrating these digital solutions into their workflow, auto body painting specialists can provide customers with transparent estimates for frame repair costs tailored to each vehicle’s unique needs.

Digital Tools for Accurate Cost Estimation

In the realm of automotive repair, especially for intricate tasks like frame repair, digital tools have emerged as game-changers. These innovative solutions offer a precise and efficient way to estimate costs, eliminating much of the guesswork traditionally associated with such repairs. By employing advanced software and 3D imaging, technicians can now meticulously assess the damage, account for labor and materials, and provide customers with accurate quotes tailored to their Mercedes Benz repair or any other automotive needs.

This digital transformation not only streamlines the estimation process but also enhances transparency for clients. With real-time data input and instant calculations, auto detailing professionals can offer immediate feedback, ensuring customers are well-informed about potential frame repair costs. Whether it’s a minor dent or significant structural damage, these tools empower both parties to make informed decisions, fostering trust in the repair process.

Benefits and Best Practices for Using Digital Technology in Frame Repair Costing

The adoption of digital technology has revolutionized frame repair costing, providing auto body shops with unprecedented precision and efficiency. Digital tools enable detailed inspections of car damage repair sites, allowing for more accurate assessments of materials needed and labor required. Through high-resolution imaging and specialized software, these tools capture every aspect of vehicle paint repair, ensuring no hidden costs are overlooked. This leads to more transparent pricing structures, enhancing customer satisfaction and trust in auto body shops.

Best practices for utilizing digital technology in frame repair cost estimation include maintaining up-to-date databases of material prices, integrating these with labor rates specific to each shop, and regularly calibrating digital measuring devices. Moreover, training staff on the latest digital tools and ensuring they are proficient in their use is essential. By following these guidelines, auto body shops can leverage digital technology not only to enhance cost estimation but also to streamline other aspects of frame repair and car damage repair processes, ultimately elevating the overall efficiency and quality of their services.

Digital tools have transformed the way frame repair costs are estimated, offering precision and efficiency. By leveraging these technologies, repair shops can provide customers with accurate quotes, streamline operations, and enhance overall transparency. This shift towards digital solutions in frame repair costing is a significant step forward, ensuring that both businesses and clients benefit from a more streamlined and reliable process.