Resistance Spot Welding (RSW) is an innovative, precise technique for auto body repair, especially effective for unibody and structural panel work. Unlike traditional methods, RSW minimizes heat damage, ensuring vehicles maintain their original shape and structural integrity while enhancing strength and aesthetic appeal. By focusing localized pressure and energy, RSW creates strong bonds with minimal heat input, ideal for dent repairs and vehicle restoration. Proper technique, optimal parameters, clean surfaces, and skilled training guarantee consistent quality in every weld.

“Unbody and structural panel repairs demand precision and strength, making resistance spot welding (RSW) an indispensable technique. This process ensures robust bonds, ideal for modern automotive unibody designs. Our article delves into the fundamentals of RSW, highlighting its advantages over traditional methods. We explore best practices, techniques, and tips for achieving successful, long-lasting welds in unibody and panel applications. By understanding and mastering RSW, auto body repair professionals can enhance efficiency, quality, and safety.”

- Understanding Resistance Spot Welding: A Fundamental Process for Unibody and Structural Panel Repairs

- Advantages of Using Resistance Spot Welding for Auto Body Repairs

- Techniques and Best Practices for Effective Resistance Spot Welding in Unibody and Structural Panel Applications

Understanding Resistance Spot Welding: A Fundamental Process for Unibody and Structural Panel Repairs

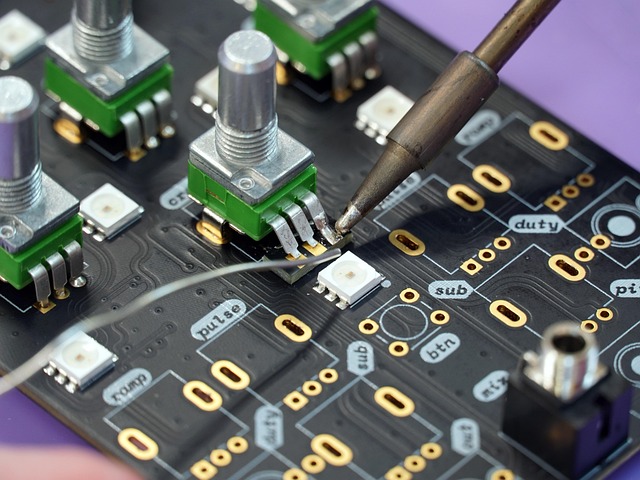

Resistance spot welding is a fundamental process that plays a crucial role in unibody and structural panel repairs across various industries, notably automotive repair. Unlike traditional welding methods, it focuses on melting a small localized area of metal using pressure and resistance heating generated by a power source. This precise technique allows for the creation of strong, permanent bonds between metals without causing significant heat-affected zones, which can weaken components in auto dent repair or bumper repair scenarios.

In automotive repair, understanding resistance spot welding is essential for ensuring structural integrity and longevity of vehicles’ unibody—the primary frame that connects all major components. By controlling the amount of energy applied during the process, technicians can achieve welds tailored to specific panel thicknesses and materials, enhancing both the structural strength and cosmetic appeal in repairs ranging from minor dents to more substantial bumper repairs. This advanced technique is a game-changer for maintaining the safety and value of vehicles throughout their lifecycle.

Advantages of Using Resistance Spot Welding for Auto Body Repairs

Resistance Spot Welding (RSW) offers several significant advantages for unibody and structural panel repairs in auto body work. Unlike traditional welding methods that can lead to excessive heat buildup and potential material distortion, RSW generates a strong, precise bond with minimal heat input. This not only ensures the integrity of the vehicle’s structure but also preserves the original shape and dimensional accuracy, crucial aspects when performing vehicle dent repair or auto dent repair.

The process involves applying controlled electrical resistance to specific points on the joint, causing the metal to melt and fuse together. This localized heating minimizes heat affected zones (HAZ), reducing the risk of material weakness or brittleness that can occur with conventional welding techniques. As a result, RSW is highly effective for intricate panel repairs and vehicle restoration projects, providing both strength and aesthetic precision.

Techniques and Best Practices for Effective Resistance Spot Welding in Unibody and Structural Panel Applications

Effective resistance spot welding is a critical process for unibody and structural panel repairs, ensuring structural integrity and quality in vehicle repair services. The key to successful welding lies in combining precise technique with optimal parameters. For unibody applications, where components like chassis and body panels are joined, it’s essential to align the parts accurately before applying force. This ensures consistent weld penetration without over-welding, preserving the original car paint repair integrity.

Best practices include using the appropriate welder for the material, maintaining clean and dry surfaces, and selecting the right electrode and current settings. During welding, controlling heat input is vital to prevent excess heating, which can lead to distortion or damage to surrounding components, like fender repair panels. Regular calibration of equipment and skill development through training ensure consistent quality in every weld, making resistance spot welding a reliable method for achieving robust structural bonds in automotive repairs.

Resistance spot welding emerges as a game-changer in unibody and structural panel repairs, offering both efficiency and strength. Its advantages, detailed in this article, include reduced material waste, faster repair times, and superior joint strength—all vital for modern auto body shops. By mastering the techniques and best practices outlined here, professionals can ensure precise and durable repairs, enhancing their workshop’s reputation and customer satisfaction. Resistance spot welding is not just a process; it’s a reliable solution that continues to revolutionize automotive craftsmanship.