Advanced adhesive applications require formulary expertise to create innovative solutions for diverse industries, especially automotive repairs. Customized formulations with high-performance polymers and additives address unique challenges, ensuring structural integrity in extreme conditions. Material compatibility is key for optimal bonding strength, achieved through proper surface preparation techniques like cleaning, drying, and priming. Meticulous application methods using specialized equipment ensure superior bonding durability under high stress, extending the lifespan of adhesive applications across various sectors.

Unleash the power of advanced adhesive applications and discover the key elements that set them apart. In this comprehensive guide, we explore the intricate world of high-performance adhesives, delving into formulations that defy traditional bonds. From material compatibility and meticulous surface preparation to innovative application techniques, each step ensures optimal bonding. Master these elements, and you’ll unlock solutions for challenging industrial applications, revolutionizing how you approach adhesion in today’s advanced manufacturing landscape.

- Understanding Advanced Adhesive Formulations

- Material Compatibility and Surface Preparation

- Application Techniques for Optimal Bonding

Understanding Advanced Adhesive Formulations

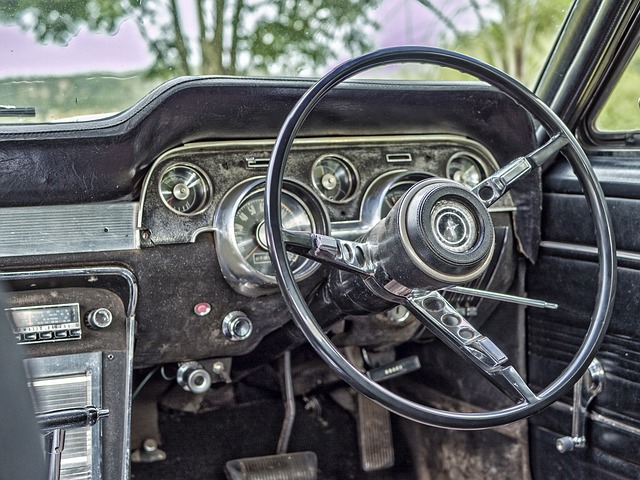

In the realm of advanced adhesive applications, understanding formulation is key to unlocking innovative solutions across various industries. Adhesives have evolved far beyond basic bonding agents, incorporating specialized chemicals and synthetic resins that cater to specific needs. For instance, in automotive sectors, advanced adhesives are instrumental in efficient fender repair and autobody repairs, ensuring structural integrity while minimizing repair times. These formulations often include high-performance polymers, fillers, and additives designed to withstand extreme conditions, from temperature fluctuations to exposure to corrosive elements.

By tailoring these formulations, manufacturers can address challenges unique to specific applications. Whether it’s a precise scratch repair or complex assembly lines requiring strong, durable bonds, advanced adhesive technologies offer versatile solutions. For example, some adhesives are engineered to bond effectively with difficult-to-attach materials, while others provide exceptional flexibility and resistance to shock and vibration, crucial for industries like aerospace and electronics manufacturing. This level of customization ensures that every advanced adhesive application meets precise requirements, driving efficiency and quality in modern production processes.

Material Compatibility and Surface Preparation

In advanced adhesive applications, material compatibility plays a pivotal role in ensuring optimal bonding strength and longevity. When selecting an adhesive for specific tasks like collision repair at a car dent repair shop or auto repair near me, understanding the chemical properties of both the adhesive and the substrate (surface to be bonded) is essential. Adhesives must be compatible with materials such as metals, plastics, glass, or composites to form strong bonds that withstand environmental factors and stress. Compatibility ensures minimal absorption, reaction, or degradation, enhancing the overall performance of the adhesive in diverse automotive repair scenarios.

Proper surface preparation is another critical element for successful advanced adhesive applications. Before applying any adhesive, surfaces must be thoroughly cleaned, dried, and treated as needed to achieve maximum bonding potential. This includes removing contaminants like grease, dust, or debris that could interfere with adhesion. For auto repair near me or collision repair center professionals, this may involve sanding, priming, or using specific cleaning agents to create a clean, roughened surface that allows the adhesive to penetrate effectively. Adequate preparation ensures a strong bond between the adhesive and the substrate, promoting long-lasting results in car dent repair or other auto repair services.

Application Techniques for Optimal Bonding

In the realm of advanced adhesive applications, understanding application techniques is key to achieving optimal bonding. Whether it’s for automotive repairs, such as car bodywork services or car damage repair, or intricate classic car restoration projects, the method by which adhesives are applied significantly impacts overall performance and durability. Professionals in this field employ various techniques, each tailored to specific materials and bond requirements. For instance, precise surface preparation is essential; this involves cleaning, priming, and treating surfaces to ensure adhesives adhere effectively.

For complex assembly tasks, specialized equipment like dispensers, rollers, or sprayers can be utilized for accurate adhesive placement and even coating. In automotive applications, these methods facilitate efficient car damage repair by allowing for precise adhesive application, reducing wastage, and ensuring structural integrity in the final bonding process. This attention to detail is crucial when considering the high-stress environments many bonded components encounter, ultimately contributing to the longevity of advanced adhesive applications in cars and beyond.

Advanced adhesive applications demand a deep understanding of key elements like formulation, material compatibility, and application techniques. By mastering these aspects, professionals can achieve superior bonding strength and durability across diverse industries. Incorporating these strategies into your workflow ensures optimal results for any complex adhesion challenge, making advanced adhesives an indispensable tool for innovation and progress.