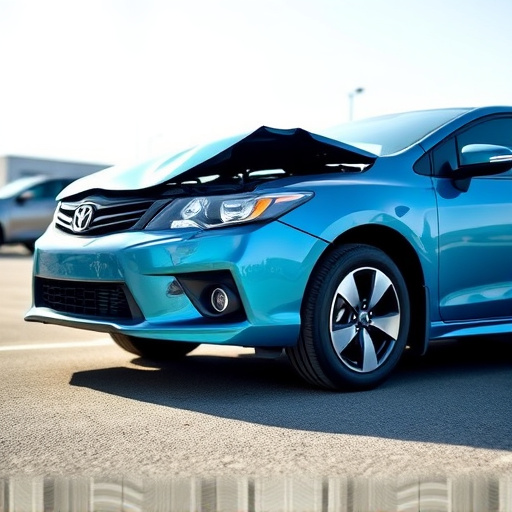

Collision repair benchmarking is a strategy for auto body shops to assess their performance against industry standards, focusing on key metrics like equipment usage, technical skills, workflow management, and cycle times for vehicles like Mercedes. By identifying gaps in resources and technologies through comparisons with best practices, shops can optimize operations, improve quality, enhance efficiency, and stay competitive in the market by strategically investing in advanced systems such as robotic welding or digital body shop management.

Collision repair benchmarking is a powerful tool that helps automotive shops identify areas for improvement. By comparing their operations to industry standards, shops can uncover equipment and technology gaps that hinder efficiency and profitability. This article explores the process of collision repair benchmarking, focusing on how it reveals investment needs in both machinery and cutting-edge technology. We’ll delve into each step, from understanding benchmarking methodologies to prioritizing investments for superior shop performance.

- Understanding Collision Repair Benchmarking

- Identifying Equipment and Technology Gaps

- Prioritizing Investment for Optimal Shop Performance

Understanding Collision Repair Benchmarking

Collision repair benchmarking is a process that involves comparing a shop’s performance and capabilities against industry standards and best practices. It’s a crucial tool for identifying areas where a car body repair or Mercedes Benz repair shop can enhance efficiency, quality, and profitability. By analyzing various aspects of vehicle repair processes, shops can understand their position in the market and pinpoint specific investment needs.

This benchmarking approach allows businesses to assess everything from equipment and technology usage to technical skills and workflow management. For instance, comparing cycle times for different car makes, such as a Mercedes Benz, can reveal inefficiencies and opportunities to invest in more advanced tools or training programs. Effective collision repair benchmarking provides a clear roadmap for strategic decision-making, ensuring that shops stay competitive and meet evolving customer expectations in the vehicle repair sector.

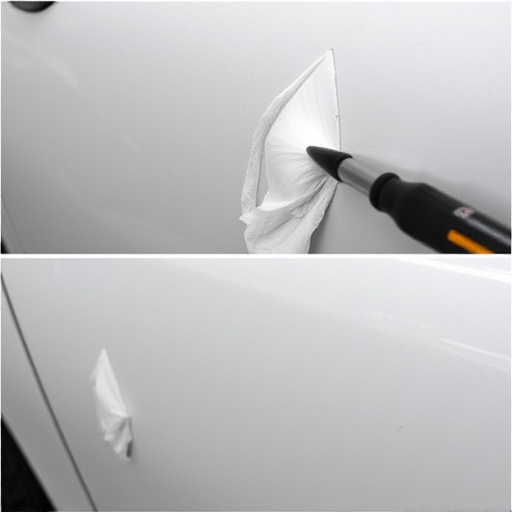

Identifying Equipment and Technology Gaps

In the realm of collision repair benchmarking, identifying equipment and technology gaps is a critical step. By comparing a collision repair shop’s current resources with industry standards and best practices, it becomes evident where enhancements are needed. This process involves assessing every aspect of the car damage repair process, from estimating and diagnostics to painting and final inspection. Gaps might include outdated tools, lack of advanced diagnostic equipment, or insufficient training for staff on new technologies in automotive restoration.

Collision repair benchmarking provides a clear roadmap for investing in the right equipment and technology. For instance, a shop may realize they are behind in robotic welding techniques, which could significantly streamline their operations and improve quality. Similarly, digital body shop management systems can enhance efficiency and accuracy in estimating and tracking repairs. By addressing these gaps, collision repair shops can elevate their service offerings, ensuring they remain competitive and meet evolving customer expectations.

Prioritizing Investment for Optimal Shop Performance

In the dynamic landscape of collision repair and car restoration, optimizing equipment and technology is key to achieving superior shop performance. Collision repair benchmarking plays a pivotal role in identifying areas where investments can significantly enhance operational efficiency and customer satisfaction. By comparing a shop’s current capabilities with industry best practices, stakeholders gain invaluable insights into what technologies and tools are essential for cutting-edge autobody repairs. This data-driven approach allows for strategic prioritization of investment, ensuring that resources are allocated to areas that will have the most substantial impact on overall performance.

For instance, adopting advanced robotic welding systems or state-of-the-art paint spraying equipment could streamline collision repair processes, reducing both labor costs and cycle times. Such investments not only elevate the quality of autobody repairs but also enhance the shop’s competitive edge in a crowded market. Through meticulous collision repair benchmarking, businesses can navigate the intricate labyrinth of technological advancements, making informed decisions that drive their success in the long run.

Collision repair benchmarking is a powerful tool that enables auto body shops to assess their current equipment and technology, identify gaps, and prioritize investments. By understanding where they stand in comparison to industry standards and best practices, shop owners can make informed decisions to enhance operational efficiency, reduce costs, and ultimately deliver superior customer satisfaction. Implementing the strategies outlined in this article will empower collision repair facilities to stay competitive and thrive in a rapidly evolving automotive landscape.