Certified welding techniques are vital for modern manufacturing and automotive repair, ensuring precision and quality. Standards from organizations like AWS and ISO guide various processes, promoting sustainability by minimizing environmental impact. These techniques prioritize eco-friendly materials and efficient practices, reducing waste and toxic emissions. Robotic systems and cleaner energy sources further enhance efficiency while contributing to a greener future.

In today’s eco-conscious world, environmental considerations are integral to every industry. Certified welding techniques emerge as a sustainable solution, offering both quality and ecological benefits. This article explores the intersection of environmental stewardship and advanced welding practices. We delve into understanding certified welding standards, examining the impact of eco-friendly materials, and uncovering efficient practices that minimize the industry’s carbon footprint. By adopting these techniques, businesses can contribute to a greener future while maintaining superior weld integrity.

- Understanding Certified Welding Standards

- Impact of Eco-Friendly Welding Materials

- Efficient Practices for Reduced Environmental Footprint

Understanding Certified Welding Standards

Certified welding techniques are a cornerstone of modern manufacturing and automotive repair, ensuring precision and quality in every joint. These standards, developed by organizations like the American Welding Society (AWS) and ISO, outline specific procedures, qualification criteria, and performance requirements for various welding processes. Adherence to these guidelines is vital not only for maintaining structural integrity but also for minimizing environmental impact.

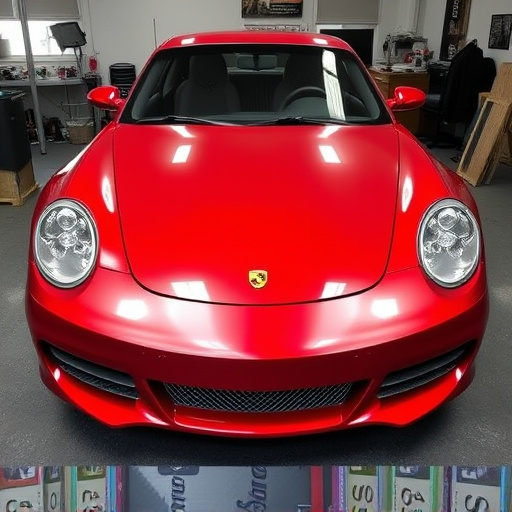

By adopting certified welding techniques, such as those used in Mercedes-Benz collision repair or vehicle dent repair, professionals can reduce the risk of contamination from toxic substances often associated with traditional welding methods. This is particularly important in an era where sustainable practices are increasingly demanded, even in high-precision car damage repair scenarios.

Impact of Eco-Friendly Welding Materials

The choice of materials in welding processes significantly contributes to environmental sustainability, especially in industries like automotive collision repair and vehicle paint repair. Certified welding techniques embrace eco-friendly options, reducing the ecological footprint associated with traditional methods. For instance, using biodegradable or recycled content-based weldments minimizes waste generation and lowers the risk of toxic emissions during production and disposal.

These sustainable materials often perform comparably to conventional counterparts, ensuring structural integrity in applications like car collision repair. By adopting such practices, welding professionals contribute to a greener environment while meeting industry standards. This shift towards eco-friendly welding materials is not only beneficial for the planet but also opens doors to innovation and cost savings in various sectors, including automotive and vehicle paint repair processes.

Efficient Practices for Reduced Environmental Footprint

In the realm of certified welding techniques, efficient practices play a pivotal role in reducing the environmental footprint. Techniques such as robotic welding and automated systems not only enhance production speed but also minimize material waste. This is particularly beneficial in industries like automotive body work, where precision and sustainability go hand in hand. By adopting these advanced methods, manufacturers can significantly cut down on the amount of energy and resources used during the welding process.

Additionally, focusing on cleaner energy sources and improved ventilation systems further contributes to eco-friendly practices. For instance, using electric or hydrogen welding machines reduces greenhouse gas emissions compared to traditional fuel-based systems. In the context of car dent repair, these certified techniques ensure that the environment is protected while delivering high-quality results. This holistic approach not only benefits businesses but also fosters a greener future for all.

Certified welding techniques play a pivotal role in minimizing environmental impact. By understanding and adhering to strict standards, embracing eco-friendly materials, and implementing efficient practices, the welding industry can significantly reduce its carbon footprint. These sustainable approaches not only benefit the planet but also enhance the reputation of businesses while fostering a more responsible and competitive market for certified welding services.