Dog leg repair uses high-strength structural adhesives to fix complex body panel angles caused by accidents or wear, offering durable, permanent fixes that surpass factory bonds. Skilled technicians prepare damaged areas meticulously and apply adhesives according to manufacturer guidelines for optimal results, preserving vehicle integrity and enhancing corrosion resistance in repairs for modern car designs.

Dog leg repairs are a common challenge for structural integrity, impacting buildings’ longevity and safety. This article delves into effective solutions through an understanding of dog leg repair techniques and the pivotal role of structural adhesive bonding. We explore best practices ensuring long-lasting repairs, providing insights crucial for professionals navigating this critical aspect of building maintenance. By embracing advanced methods, we can mitigate risks and promote robust, enduring structures.

- Understanding Dog Leg Repair Techniques

- The Role of Structural Adhesive Bonding

- Best Practices for Long-Lasting Repairs

Understanding Dog Leg Repair Techniques

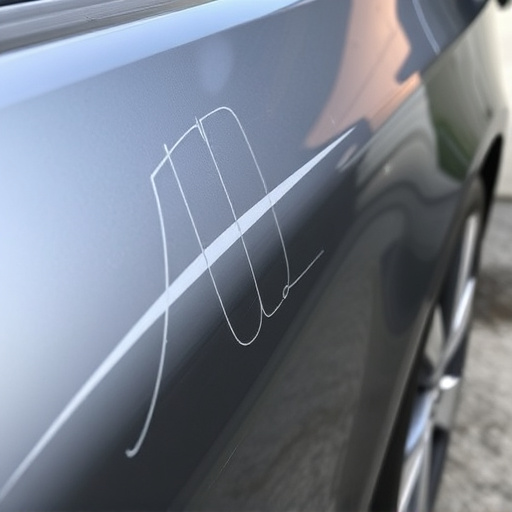

Dog leg repair is a specialized technique within the automotive industry, focusing on correcting structural damage to vehicle bodies, particularly in areas where panels meet at an angle—a common occurrence in car accidents or during regular wear and tear. This intricate process involves understanding the underlying structure of the vehicle and the principles of bonding to ensure long-lasting repairs. Professional car bodywork services employ advanced methods to achieve precise alignment and seamless integration of damaged components, enhancing the overall structural integrity of the car restoration.

The expertise lies in using structural adhesives designed for high-strength bonding between various materials used in modern vehicles. These adhesives play a pivotal role in dog leg repair by providing a durable and flexible connection, often surpassing the strength of the original factory bond. Vehicle restoration specialists carefully apply these adhesives to match the curve and angle of the damaged area, ensuring a robust fix that can withstand routine stress and environmental factors. This meticulous approach guarantees not only the aesthetic appeal but also the safety and reliability of the restored vehicle.

The Role of Structural Adhesive Bonding

Structural adhesive bonding plays a pivotal role in dog leg repair, offering a robust and long-lasting solution for damaged vehicles. In the context of bumper repair and vehicle collision repair, this technique is invaluable for restoring cars to their pre-accident condition. It involves precisely applying high-performance adhesives to join components like car bodywork panels, ensuring strength equal to or greater than that of the original manufacturing bond.

This method is particularly beneficial in modern car design where complex geometry and lightweight materials are prevalent. For instance, during a car bodywork services procedure, structural adhesive bonding can be used to seamlessly reattach fenders, doors, or hoods, preserving the vehicle’s aesthetic appeal and structural integrity. This approach also reduces the need for traditional mechanical fasteners, resulting in improved corrosion resistance and overall durability.

Best Practices for Long-Lasting Repairs

When conducting dog leg repair, adhering to best practices ensures long-lasting results and maintains vehicle structural integrity. Start by preparing the damaged area meticulously; this includes cleaning and degreasing to eliminate any contaminants that could compromise the adhesive bond. Sanding the surfaces slightly can also enhance adhesion. Using high-quality structural adhesives specifically designed for automotive applications is crucial, as these products offer superior strength and durability.

Proper application techniques are key. Follow manufacturer instructions regarding curing times and conditions. Ensure even distribution of the adhesive and consider using a vacuum system to remove any air bubbles, which can weaken the bond. Additionally, for auto repair near me services that involve dog leg repair, training and certification for technicians in structural adhesive bonding are essential. This guarantees skilled execution and promotes long-term reliability.

In conclusion, dog leg repair using structural adhesive bonding is a game-changer in ensuring long-lasting and robust fixings. By understanding the techniques and best practices highlighted in this article, professionals can navigate the process effectively, delivering superior results for various applications. Structural adhesive bonding proves to be a reliable method for repairing dog legs, offering both strength and durability, thereby revolutionizing the way we approach these repairs in today’s world.