Factory seam duplication, a meticulous automotive repair art, requires specialized tools and guidelines for flawless results. It involves rigorous surface preparation to remove contaminants, followed by specific equipment like cleaners, sanders, and primers. This process ensures accurate replication of original factory finishes, vital for auto glass repair and bodywork, maintaining structural integrity in complex restoration projects.

In the manufacturing industry, achieving perfect duplicates of seams is crucial for maintaining consistency and quality. This article guides you through the essential steps of surface preparation for successful factory seam duplication. We’ll explore the understanding of factory seam duplication requirements, unearth essential tools needed, and provide a step-by-step guide to ensure seamless results. Master these techniques and elevate your production standards.

- Understanding Factory Seam Duplication Requirements

- Essential Tools for Surface Preparation

- Step-by-Step Guide to Achieving Seamless Results

Understanding Factory Seam Duplication Requirements

Factory seam duplication is a precise process that requires meticulous preparation to ensure optimal results. Understanding the specific requirements and standards set by automotive manufacturers is paramount for success in this specialized field. Every vehicle manufacturer has its own set of guidelines and specifications, which include detailed instructions on surface preparation before seam duplication. This step is crucial as it lays the foundation for achieving a seamless (no pun intended) and durable repair, akin to the original factory-built quality.

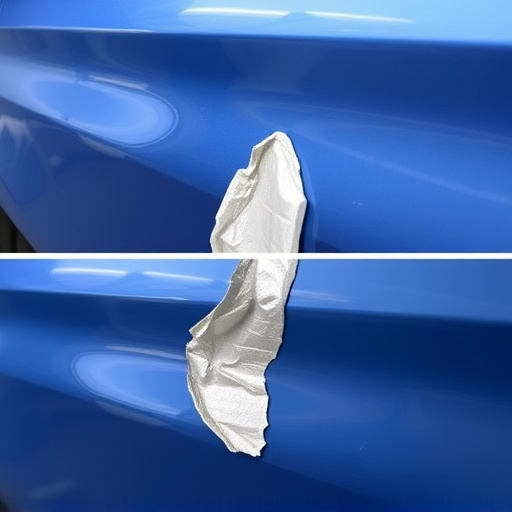

When preparing surfaces for factory seam duplication, whether it’s for car damage repair, auto glass repair, or automotive repair services, several factors come into play. Skilled technicians must carefully assess the damage, clean the area thoroughly, and ensure proper adhesion of replacement parts. The surface must be free from contaminants, grease, and dust to guarantee a secure bond. This meticulous attention to detail is what transforms a simple seam duplication process into an art form, ensuring that vehicles return to the road with repairs that are virtually indistinguishable from the original factory work.

Essential Tools for Surface Preparation

Achieving precise factory seam duplication requires a well-equipped toolkit and meticulous surface preparation. Essential tools for this process include specialized cleaners, sanders, and primers designed to remove impurities and ensure a clean canvas for replication. High-quality abrasives are crucial for achieving the right texture, while chemical strippers can effectively eliminate stubborn residues from previous repairs or coatings.

For auto glass repair, vehicle body repair, and even routine vehicle repair services, having the right surface prep essentials is paramount. These tools play a pivotal role in the success of any duplication endeavor, ensuring that the final result closely mimics the original factory finish.

Step-by-Step Guide to Achieving Seamless Results

Achieving flawless factory seam duplication requires a meticulous approach and precise techniques. Here’s a step-by-step guide to ensure optimal results:

1. Surface Preparation: Begin by thoroughly cleaning the area around the seam using specialized solvents suitable for the material, whether it’s metal, plastic, or composite. This removes any contaminants that could hinder adhesion during duplication. For an auto glass repair or automotive restoration project, a streak-free finish is crucial to maintaining structural integrity and aesthetic appeal.

2. Sand and Prime: Lightly sand the surface to create a rough texture that allows for better bonding. Apply a high-quality primer designed for factory seam duplication. This step is vital in creating a strong bond between the original and replicated seam, ensuring long-lasting durability. For complex projects like car repair shop restorations, this process might need to be repeated for optimal adhesion.

Achieving precise and consistent results in factory seam duplication requires a thorough understanding of the process and the right preparation tools. By mastering the essential steps outlined in this guide, you’ll be well-equipped to ensure seamless duplications every time. Remember, proper surface prep is half the battle won—invest in quality tools and follow a meticulous approach for optimal outcomes in your factory seam duplication endeavors.