Custom fabrication is a key technique in auto body modification, allowing for unique designs and precise fitting. It offers superior quality and performance but requires skilled technicians, advanced equipment, and rare materials. Safety is paramount; comprehensive assessments, structural integrity, high-quality materials, and hazard mitigation are essential to prevent future failures.

In the realm of custom auto body modification work, fabrication plays a pivotal role, transforming ordinary vehicles into unique masterpieces. This article delves into the intricate world of fabrication techniques used to enhance and customize automotive bodies. We explore the benefits and challenges of integrating custom fabricated parts, shedding light on safety considerations that ensure these modifications not only look breathtaking but also remain road-ready. Prepare to uncover the secrets behind bringing your auto body vision to life.

- Understanding Fabrication Techniques for Auto Body Mods

- Benefits and Challenges of Custom Fabricated Parts

- Safety Considerations in Auto Body Modification Work

Understanding Fabrication Techniques for Auto Body Mods

Understanding Fabrication Techniques for Auto Body Mods

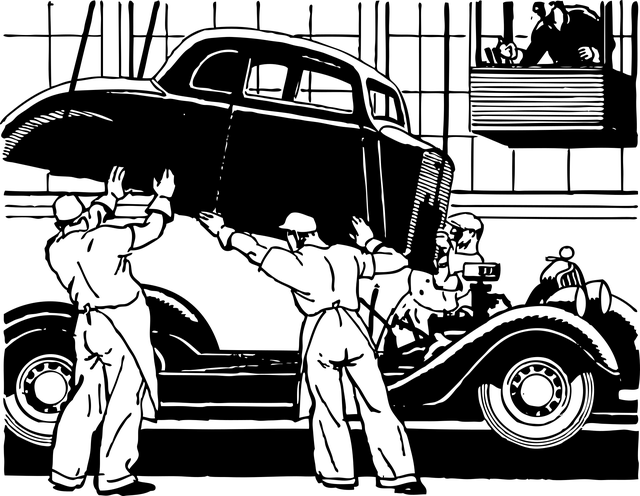

In the realm of custom auto body modification work, fabrication is a crucial process that transforms vehicles into unique artistic expressions. It involves various techniques to reshape and enhance automotive structures. Skilled technicians employ methods like cutting, bending, welding, and shaping metal panels to create intricate designs. These skills are essential for achieving precise measurements and ensuring structural integrity, especially when dealing with custom body kits or extensive modifications.

The art of fabrication goes beyond simple repair; it focuses on creating or restoring components to match a customer’s vision. This can include dent removal and vehicle paint repair as part of the pre-fabrication process, preparing the surface for new designs. Auto body services that specialize in customization often utilize advanced equipment and techniques to accommodate complex demands, ultimately delivering one-of-a-kind vehicles tailored to individual preferences.

Benefits and Challenges of Custom Fabricated Parts

Custom fabrication plays a pivotal role in the realm of auto body modification, offering both unparalleled benefits and unique challenges. When it comes to enhancing or restoring vehicles, custom-made parts provide an array of advantages. For instance, they allow for intricate designs and one-of-a-kind aesthetics that mass-produced components simply cannot match. This level of customization enables car enthusiasts and customizers to bring their creative visions to life, making each vehicle truly unique. Furthermore, fabrication ensures precision fitting, superior quality, and the use of high-grade materials, resulting in enhanced performance and longevity.

However, the path to creating these bespoke parts is not without hurdles. Custom fabrication requires specialized skills, advanced equipment, and a deep understanding of automotive design principles. It involves meticulous measurement, intricate welding, and careful consideration of structural integrity. Moreover, sourcing rare or hard-to-find materials can pose a significant challenge for auto body services. Despite these obstacles, the ability to create custom components offers car owners solutions for even the most unique repair or modification needs, such as correcting imperfections from previous accidents or achieving a specific look that requires precise dimensions and finishes, including top-notch auto painting.

Safety Considerations in Auto Body Modification Work

In the realm of custom auto body modification work, safety is paramount. As modifications can involve intricate changes to a vehicle’s structure and components, such as adding new parts or extensively altering existing ones, ensuring the integrity of the automobile is crucial for both the modifier and future occupants. This includes comprehensive assessments to verify that all structural elements, including frames, panels, and safety features like auto glass repair and airbags, remain functional and secure after modifications. Proper fabrication techniques, employing high-quality materials and equipment, are essential to prevent compromising the vehicle’s overall safety, which is non-negotiable in any custom auto body modification process.

Moreover, the work environment poses unique hazards that need addressing. Auto body modification shops must adhere to stringent safety protocols, including proper ventilation for handling hazardous chemicals and substances commonly used in fabrication, as well as implementing effective measures for protecting against noise and vibration exposure. Additionally, focusing on vehicle dent repair and automotive collision repair methods that preserve original components can help reduce the risk of future structural failures, underscoring the multifaceted nature of safety considerations within this specialized trade.

Custom auto body modification is a creative and intricate process, with fabrication playing a pivotal role. By understanding advanced techniques, leveraging the benefits of custom-fabricated parts, and prioritizing safety, enthusiasts can transform their vehicles into unique expressions of art on wheels. This specialized work not only enhances aesthetics but also allows for personalization, ensuring each vehicle tells its own story.