Digital measuring systems revolutionize automotive repair with precise real-time data, enhancing efficiency, accuracy, and quality control in collision and dent repair, ultimately improving customer satisfaction through meticulous restoration of classic vehicles and minimizing re-repairs.

In today’s complex maintenance landscape, efficient and precise digital measuring systems are revolutionizing repairs. This article explores how these innovative tools can simplify even the most intricate tasks, enhancing productivity and accuracy. From unlocking hidden efficiencies to ensuring exact measurements, digital measuring systems are a game-changer. We’ll delve into their key benefits, providing a step-by-step guide to help folks navigate this exciting technology.

- Unlocking Efficiency: Digital Measuring Systems' Role

- Precision and Accuracy: The Key Benefits

- Streamlining Repairs: A Step-by-Step Guide

Unlocking Efficiency: Digital Measuring Systems' Role

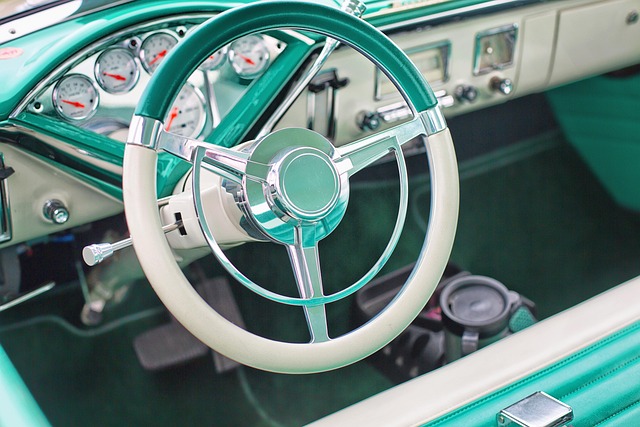

Digital measuring systems are transforming the landscape of automotive repair, revolutionizing how vehicle body shops and automotive restoration experts conduct their work. These innovative tools offer a seamless blend of technology and precision, unlocking efficiency at every turn. By seamlessly integrating advanced sensors and software, digital measuring systems provide accurate, real-time data on various aspects of a vehicle’s structure.

This capability enables automotive repair technicians to make informed decisions quickly, reducing the time typically spent on manual measurements and visual inspections. As a result, vehicle body shops can streamline their processes, allowing them to handle more jobs efficiently without compromising quality. Moreover, digital measuring systems contribute to enhanced accuracy during automotive restoration projects, ensuring that every detail is meticulously recreated to bring classic vehicles back to their former glory.

Precision and Accuracy: The Key Benefits

Digital measuring systems are transforming the landscape of automotive repair, particularly in areas like collision damage repair and vehicle dent repair. The key benefits lie in their precision and accuracy. Unlike traditional methods, these advanced tools can capture intricate details with exacting measurements, ensuring repairs are not just visually appealing but also structurally sound. This level of accuracy is crucial for restoring vehicles to their pre-incident condition, minimizing the need for costly re-repairs.

In automotive repair, where even minor deviations can affect performance and safety, precision becomes a matter of integrity. Digital measuring systems enable technicians to precisely assess damage, plan repairs, and monitor progress in real-time. This not only streamlines the repair process but also enhances overall quality control, leading to higher customer satisfaction and improved shop reputation.

Streamlining Repairs: A Step-by-Step Guide

The adoption of digital measuring systems has revolutionized car paint services and collision repair procedures. This technology provides an efficient, precise, and accurate way to assess damage, which is crucial for streamlining repairs in a vehicle body shop. Here’s a step-by-step guide on how it works:

1. Initial Assessment: Using advanced sensors and cameras, digital measuring systems capture detailed 3D images of the damaged area. This initial step allows technicians to get a clear view of the extent of the damage without physical contact, ensuring safety and reducing the risk of further complications.

2. Data Analysis: The collected data is analyzed to create comprehensive digital models of the vehicle’s affected parts. This enables precise measurement and comparison with original manufacturer specifications, facilitating more accurate repairs.

3. Customized Repair Plan: Based on the analysis, a tailored repair plan is generated, outlining specific car paint services required. This includes the exact amounts of paint needed, color matching processes, and potential additional work, ensuring every step aligns with industry standards.

4. Repair Execution: With a clear roadmap in place, collision repair services can be executed efficiently. Technicians follow the digital plan, enhancing productivity and reducing human error, leading to higher-quality outcomes.

5. Quality Assurance: Upon completion, another digital scan is performed to verify that the repairs match the original specifications. This final step ensures customer satisfaction and guarantees the vehicle’s structural integrity.

Digital measuring systems have emerged as powerful tools, revolutionizing complex repairs by offering unprecedented efficiency and precision. By adopting these innovative technologies, professionals can streamline their work processes, ensuring accurate measurements every time. This not only saves time but also enhances overall job satisfaction, allowing for more efficient and effective repairs in today’s digital era.