Advanced welding techniques like laser and robotic welding are revolutionizing industries, offering unparalleled precision, quality, and control over intricate geometries. These methods enhance structural integrity in auto body repair, enabling paintless repairs and dent removal. While requiring significant investment in equipment and safety protocols, they transform manufacturing, aerospace, and electronics by producing lighter, stronger components with tight tolerances, fostering innovation across sectors.

Delve into the future of fusion with our comprehensive guide on advanced welding techniques. From exploring specialized processes like laser and robotic welding to understanding safety protocols for cutting-edge methods, this article covers it all. We uncover how these innovative techniques are transforming industries, from automotive manufacturing to aerospace, offering enhanced precision and efficiency. Get ready to revolutionize your welds with the next generation of fusion technology.

- Exploring Specialized Welding Processes

- Equipment and Safety Considerations for Advanced Techniques

- Applications and Industries Adopting Cutting-Edge Fusion Methods

Exploring Specialized Welding Processes

In the realm of advanced welding techniques, specialized processes have emerged to cater to unique material properties and intricate fabrication requirements. Beyond traditional arc welding, professionals are exploring innovative methods like laser welding for precise and high-quality results, particularly in industries where precision is paramount. These cutting-edge approaches offer enhanced control over heat input, enabling the creation of complex geometries and fine finishes, which was previously unattainable with conventional methods.

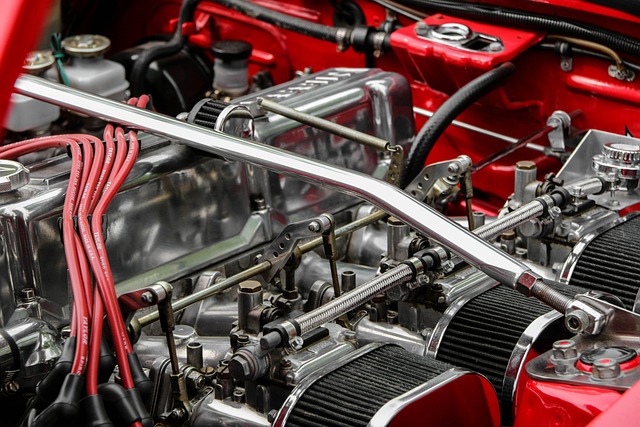

For instance, in the auto body shop, advanced welding techniques have revolutionized car dent removal and paintless dent repair processes. By leveraging specialized equipment and expert knowledge, technicians can now restore vehicles to their original condition with minimal scorch marks or structural imperfections. This not only enhances the aesthetic appeal of repaired cars but also ensures longevity and structural integrity, showcasing the practical applications of these advanced welding techniques in everyday industries.

Equipment and Safety Considerations for Advanced Techniques

When adopting advanced welding techniques, such as robotic welding or laser welding, a significant emphasis must be placed on equipment and safety considerations. These cutting-edge methods demand specialized machinery, precise calibration, and consistent maintenance to ensure optimal performance. For instance, in automotive restoration or Mercedes Benz collision repair, robotic welders offer unparalleled precision, enabling intricate and complex joins. However, they also necessitate robust safety protocols due to their high-speed operations and potential for hazardous materials.

Similarly, laser welding, while highly efficient for precise, clean cuts, requires meticulous attention to safety. The intense heat and focused energy beam can pose risks to operators and surrounding structures if not properly contained and controlled. Thus, car repair services employing these advanced techniques must invest in state-of-the-art equipment, regular staff training on safety protocols, and the implementation of stringent workplace safety standards to mitigate risks effectively.

Applications and Industries Adopting Cutting-Edge Fusion Methods

The adoption of advanced welding techniques is reshaping various industries, demonstrating their versatility and precision in applications that demand exceptional strength and aesthetics. From aerospace to automotive, these cutting-edge methods are driving innovation in vehicle repair and fabrication. In auto collision centers and body shop services, for instance, advanced welding techniques ensure the structural integrity of vehicles while allowing for intricate design elements, thereby enhancing both safety and visual appeal.

In addition, industries such as manufacturing, electronics, and medical devices are leveraging these technologies to create complex components with tight tolerances. The ability to join materials like aluminum, stainless steel, and titanium with unparalleled precision has led to the development of lighter, stronger, and more durable products across multiple sectors. This evolution in fusion methods is not only revolutionizing traditional vehicle repair but also opening new possibilities for innovation in diverse fields.

Advanced welding techniques are transforming industries worldwide, offering unprecedented precision, efficiency, and material strength. By delving into specialized processes, adopting modern equipment, and prioritizing safety, professionals can unlock innovative applications across diverse sectors. As these cutting-edge fusion methods continue to evolve, staying informed about the latest developments will empower welders to contribute to groundbreaking projects, ensuring a future where advanced welding is an engine of progress and innovation.