Unibody frame repair is a critical component of modern automotive maintenance, focusing on the integrated structure of chassis, body, and frame. Advanced tools like 3D scanning revolutionize this process by providing precise measurements and detailed imaging, enabling technicians to detect even minute misalignments. This strategic approach ensures flawless restoration, crucial for safety and performance in collision scenarios. By integrating unibody repair with tire services, comprehensive vehicle maintenance, and strategic tool selection, workshops can offer holistic solutions, enhancing customer satisfaction through thorough examination of every vehicle component.

Unibody frame repair is a game-changer in automotive manufacturing, offering lightweight, safe, and durable vehicle structures. As demand grows for efficient, high-quality repairs, structural scanning tools become essential. This article explores the key features and functions of these advanced technologies, providing best practices for their implementation in unibody frame repair. Discover how these tools enhance precision, speed, and overall efficiency, ensuring optimal vehicle performance and safety.

- Understanding Unibody Frame Repair and Its Importance

- Key Features and Functions of Structural Scanning Tools

- Best Practices for Implementing Unibody Frame Repair with Scanning Tools

Understanding Unibody Frame Repair and Its Importance

Unibody frame repair is a specialized process that involves the restoration and reinforcement of a vehicle’s structural integrity. In modern automobiles, the unibody—a single-piece construction that combines the chassis, body panels, and frame—is integral to safety and performance. When damage occurs, whether from accidents or regular wear and tear, precise repairs are crucial to maintain the vehicle’s structural integrity and ensure safe operation.

This type of repair is essential for several reasons, including enhanced safety features, improved vehicle dynamics, and extended lifespan. Skilled technicians use advanced tools and techniques to accurately locate and address damage, often involving intricate metalworking and precision measurements. By focusing on unibody frame repair, vehicle repair services can deliver high-quality outcomes, matching the original manufacturing standards while also providing essential tire services and overall vehicle maintenance as needed.

Key Features and Functions of Structural Scanning Tools

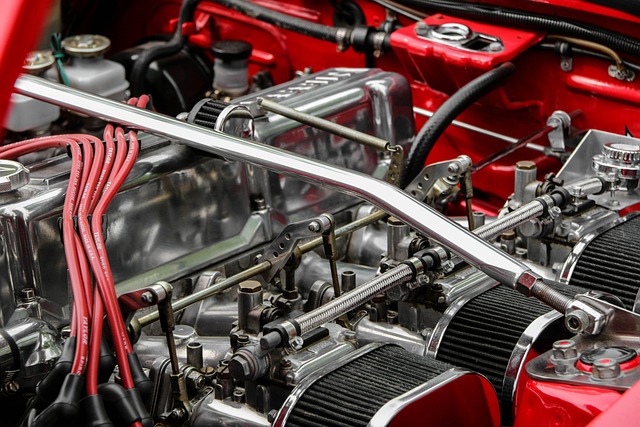

Structural scanning tools have revolutionized unibody frame repair processes in collision repair centers. These advanced technologies offer precise measurements and detailed imaging capabilities, allowing technicians to accurately assess damage and plan repairs with utmost efficiency. Key features such as 3D scanning, digital mapping, and real-time data analysis enable auto dent repair experts to identify even subtle misalignments and deformations within the unibody frame, ensuring a flawless restoration.

By integrating these tools into their workflows, bumper repair specialists can streamline the entire process from initial damage assessment to final quality control checks. The ability to capture intricate dimensions and compare them against original factory specifications facilitates accurate replacement parts selection and precise reinstatement of the vehicle’s structural integrity. This level of precision is particularly crucial in unibody frame repairs, where minimizing residual damage is paramount for optimal safety and performance, especially in cases involving complex collision scenarios or extensive bodywork.

Best Practices for Implementing Unibody Frame Repair with Scanning Tools

Implementing unibody frame repair with scanning tools requires a strategic approach to ensure precision and quality. Begin by selecting the right tool for your needs; different scanners offer varying capabilities, so choose one that aligns with your workshop’s requirements. Calibration is key; regularly test and calibrate your equipment to maintain accuracy. This involves comparing scan data against known standards and adjusting settings as needed. Proper training is another best practice. Ensure your technicians understand the software and hardware, allowing them to interpret scans effectively and make informed decisions.

Integration with other vehicle repair services like auto glass repair and auto detailing can enhance the process. Scanning tools provide a detailed view of the unibody, aiding in identifying potential issues that may require additional work. By combining these technologies, workshops can offer comprehensive solutions, improving customer satisfaction and ensuring every aspect of their vehicles is examined thoroughly.

Unbody frame repair, a revolutionary process in automotive restoration, relies on advanced structural scanning tools to ensure precision and quality. By accurately assessing and analyzing vehicle frames, these tools enable technicians to perform efficient repairs, enhancing safety and vehicle performance. Implementing best practices, including proper tool calibration and comprehensive data analysis, is key to achieving superior results in unibody frame repair.