Mastering metal properties is key to successful panel beating in automotive repairs. Different metals like aluminium and steel require distinct techniques due to variations in ductility, strength, and heat responsiveness. Skilled technicians adapt their methods for each metal, ensuring structural integrity and aesthetic appeal. Aluminium's popularity demands specialized dent removal techniques, while steel's robustness and versatility make it ideal for bodywork, with controlled hammering and annealing enhancing its properties.

Unleash the art of precision crafting with our guide on panel beating techniques, tailored for various metal types. From the versatility of aluminum to the strength of steel, each requires a unique approach. Understanding metal properties is key to achieving flawless results.

Explore effective methods for aluminum, a common choice due to its lightweight yet durable nature, and discover specialized techniques for steel, harnessing its inherent strength. Dive into these strategies to master panel beating like a professional.

- Understanding Metal Properties for Effective Panel Beating

- Techniques for Aluminum: A Versatile and Common Choice

- Steel's Strength: Specialized Beating Methods Revealed

Understanding Metal Properties for Effective Panel Beating

Understanding the unique properties of different metal types is crucial for achieving successful and precise panel beating results. Each metal has its own characteristics, such as ductility, strength, and responsiveness to heat treatment. For instance, lighter metals like aluminium require a more delicate approach due to their high malleability, while steels, known for their durability, demand stronger force and specific techniques to avoid deformation or cracking.

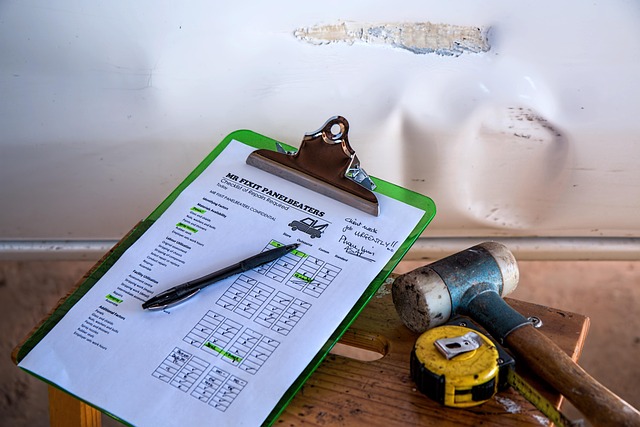

When undertaking panel beating tasks, especially in automotive repair services, considering the metal’s properties is essential for effective car dent removal or auto glass replacement processes. The right tools, heat treatment methods, and techniques tailored to each metal type ensure better retention of structural integrity and aesthetic appeal. Proficiency in these aspects allows panel beaters to deliver high-quality work across various projects, from minor dents to complex body repairs.

Techniques for Aluminum: A Versatile and Common Choice

Aluminum is a popular choice for panel beating due to its versatility and widespread use in various industries, including automotive manufacturing. For mercedes benz collision repair or any vehicle with aluminum panels, techniques must be tailored to respect the unique properties of this metal. One key consideration is its tendency to deform plastically when subjected to force, which can lead to permanent dimpling if not managed carefully.

Skilled panel beaters employ specific methods for dent removal on aluminum, often utilizing specialized tools and techniques to minimize this risk. The process typically involves heating the dented area to temper the metal, making it more malleable, before applying precise pressure to return the panel to its original shape. This meticulous approach is crucial in achieving a flawless finish, especially when addressing hail damage repair, ensuring that the aluminum body panels not only look good but also maintain their structural integrity.

Steel's Strength: Specialized Beating Methods Revealed

Steel is a robust and versatile metal commonly used in vehicle bodywork, making it a top choice for panel beating. Its exceptional strength and durability are attributed to its unique crystal structure and ability to withstand significant deformation without failure. When performing panel beating on steel, technicians often employ specialized methods to enhance its inherent properties further.

One technique involves using controlled hammering to reshape the metal while maintaining its structural integrity. This method is particularly effective for vehicle dent repair, allowing for precise adjustments to the car’s bodywork. Another approach includes the use of heat treatment, where steel is heated to specific temperatures to improve its malleability and resistance to cracking. This process, known as annealing, enables detailed refinements in panel beating, ensuring a seamless and robust car body.

Panel beating is an art that requires a deep understanding of metal properties and tailored techniques for optimal results. Whether working with aluminum’s versatility or steel’s strength, mastering these distinct approaches ensures every project yields durable and aesthetically pleasing finishes. By combining scientific knowledge with practical skillsets, panel beaters can create remarkable transformations across various metal types.