Adhesive bonding techniques are vital in automotive manufacturing and repairs, offering strong bonds between diverse materials like metal, plastic, and composites. Specialized adhesives are crucial for processes like paintless dent repair and collision repair, with OEM guidelines emphasizing durability, water resistance, and aesthetic harmony. Choosing the right adhesives based on material compatibility, environmental conditions, and desired bond strength is key to achieving optimal performance and durability. Effective implementation of these techniques enhances structural integrity and minimizes future repairs for modern and vintage cars.

In today’s automotive industry, precision and durability in manufacturing are paramount. Original Equipment Manufacturers (OEMs) increasingly rely on adhesive bonding techniques to achieve seamless, strong, and long-lasting connections. This article delves into the essentials of adhesive bonding basics tailored for automotive applications, guides readers through choosing the right adhesives, and explores implementation strategies for optimal performance. Discover how these techniques revolutionize vehicle assembly, ensuring safety and efficiency.

- Understanding Adhesive Bonding Basics for Automotive Applications

- Choosing the Right Adhesives for Optimal Performance and Durability

- Implementation Strategies: Effective Techniques for Seamless Bonding

Understanding Adhesive Bonding Basics for Automotive Applications

Adhesive bonding techniques play a pivotal role in modern automotive manufacturing and repairs. To grasp their potential fully, it’s essential to understand the basics: Adhesives act as a bridge between two surfaces, creating a strong, lasting bond that can withstand various forces and environmental conditions. In automotive applications, these bonds are crucial for everything from assembling body panels and structural components to securing interior trim and electrical connectors.

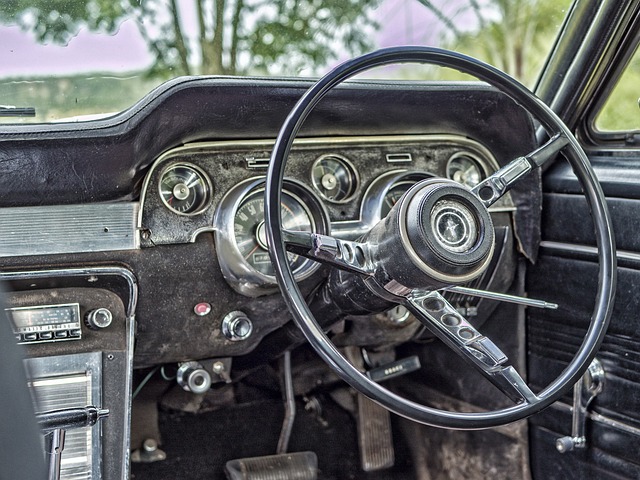

Knowing how different adhesives interact with various materials—like metal, plastic, and composite—is key. Manufacturers recommend specific adhesive bonding techniques tailored to the material mix and desired outcome. For instance, in paintless dent repair services, specialized adhesives enable precise restoration of automotive bodies without the need for extensive painting or reshaping. Similarly, OEM guidelines for automotive repair services often emphasize the use of high-performance adhesives to ensure durability, water resistance, and aesthetic harmony across the vehicle’s exterior and interior.

Choosing the Right Adhesives for Optimal Performance and Durability

Choosing the right adhesives is paramount for achieving optimal performance and durability in automotive adhesive bonding techniques. When undertaking car dent removal or intricate car collision repair tasks, selecting the appropriate adhesive becomes even more critical. Each application—from structural repairs to classic car restoration projects—requires a specific type of adhesive that aligns with material compatibility, environmental conditions, and desired bond strength. For instance, polyurethanes excel in bonding metal components while cyanoacrylates offer fast bonding for certain plastics.

OEM recommendations guide professionals in selecting adhesives tailored to specific vehicle parts and repair scenarios. By following these guidelines, technicians can ensure long-lasting bonds during car collision repair or classic car restoration processes. This not only enhances the structural integrity of vehicles but also contributes to safer driving conditions. Effective adhesive bonding techniques are key to minimizing future repairs and ensuring the longevity of both modern and vintage automobiles.

Implementation Strategies: Effective Techniques for Seamless Bonding

Implementing effective adhesive bonding techniques is paramount for achieving seamless results in automotive manufacturing and repairs. Original Equipment Manufacturers (OEMs) often recommend specific strategies to ensure durability, strength, and long-lasting bonds. One key strategy is to choose the right adhesive for each application, considering factors like substrate compatibility, environmental conditions, and required bond strength. For instance, polyurethanes or epoxy adhesives are commonly used in auto glass replacement due to their high impact resistance and ability to create strong bonds with various materials.

In addition to selecting suitable adhesives, proper surface preparation is crucial. This includes cleaning, degreasing, and roughening the surfaces to enhance adhesion. In collision centers, where repairs often involve auto painting, ensuring that adhesive bonding techniques align with paint integrity and bond strength standards is essential to prevent future issues like delamination or peeling. By combining precise application methods, such as using specialized equipment for accurate dispensing and curing conditions, OEMs can guarantee consistent and high-quality results in every auto painting and repair process.

Adhesive bonding techniques, as championed by OEM recommendations, offer a robust and efficient solution for automotive manufacturing. By understanding the basics, selecting the right adhesives, and implementing effective strategies, manufacturers can ensure superior performance, enhanced durability, and seamless bonding processes. These practices not only streamline production but also contribute to the overall quality and reliability of automotive components.