The collision repair industry is transforming with advancements in paint technology, raising paint finish quality standards to new levels. Modern techniques and materials, aided by tools like advanced spray guns and CAD systems, achieve superior finishes equal to OEM standards. Standardization ensures consistent results, while advanced quality control measures include automated sanding, real-time visual inspection, and robust paint adhesion for durable, high-quality finishes that meet or exceed OEM specifications.

The collision repair industry is on the cusp of a transformative era in paint finish quality. With advancements in technology, the future promises superior finishes that are more durable and aesthetically pleasing. This article explores key developments driving these changes, including evolving paint technologies and new standardization efforts. We delve into innovative quality control measures designed to enhance longevity, ensuring that vehicles not only look new but also stand the test of time. By embracing these advancements, the industry is poised to set higher benchmarks for paint finish quality standards.

- Evolving Paint Technology for Superior Finish

- Standardization: Unifying Industry Benchmarks

- Ensuring Longevity: New Quality Control Measures

Evolving Paint Technology for Superior Finish

The evolution of paint technology is revolutionizing the collision repair industry by setting new benchmarks for paint finish quality standards. Modern automotive repair services are no longer confined to traditional methods; instead, they incorporate advanced techniques and materials that ensure a superior, seamless finish. Car body restoration processes have become more precise, allowing for intricate details and an array of vibrant colors that were once challenging to achieve.

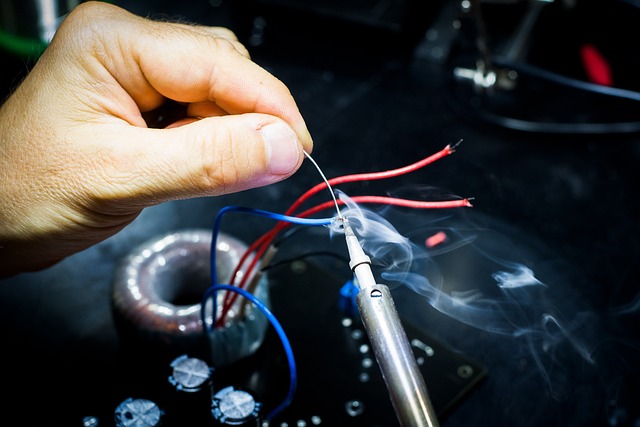

These advancements in car bodywork services are driven by the demand for high-quality, durable finishes that match the original equipment manufacturer’s standards. With the help of advanced spray guns and computer-aided design systems, technicians can now achieve consistent, flawless coats, enhancing the overall aesthetic appeal of vehicles undergoing restoration or repair. This relentless pursuit of excellence in car body restoration promises to set new trends, ensuring that vehicles not only look good but also maintain their glossy finish for longer periods.

Standardization: Unifying Industry Benchmarks

Standardization plays a pivotal role in shaping the future of paint finish quality standards within the collision repair industry. By unifying industry benchmarks, professionals can ensure consistent and superior results across various collision centers. This involves adopting standardized procedures and protocols for surface preparation, painting techniques, and quality assurance checks. Standardization not only streamlines the repair process but also enhances customer satisfaction by guaranteeing a high-quality, seamless finish that matches the original vehicle specifications.

In light of these efforts, advanced technologies like computer-aided design (CAD) systems and robotic painting equipment are increasingly integrated into collision centers. These innovations further refine the paint application process, enabling precise color matching and consistent coat thickness. As the industry continues to evolve, maintaining and raising paint finish quality standards will remain paramount in the competitive landscape of auto glass repair and car dent repair services.

Ensuring Longevity: New Quality Control Measures

In the pursuit of maintaining superior paint finish quality standards in the collision repair industry, new quality control measures are being implemented to ensure the longevity of repairs. These advanced techniques go beyond traditional methods, leveraging cutting-edge technology and rigorous testing protocols. By adopting these innovative practices, body shop services can deliver more durable and aesthetically pleasing finishes that stand the test of time.

The focus is not merely on achieving a smooth surface but also on ensuring the paint adheres robustly to the vehicle’s body, resisting chipping, fading, and other environmental damages. Collision repair services are increasingly incorporating advanced preparation techniques, such as automated sanding and precision masking, to minimize imperfections before application. Additionally, real-time visual inspection systems and spectrophotometric testing enable auto repair services to detect even subtle variations in paint composition, allowing for immediate corrections and ensuring consistency with original equipment manufacturer (OEM) standards.

The collision repair industry is on the cusp of a transformative era, as advancements in paint technology and standardized quality control measures promise to elevate paint finish quality standards to new heights. By embracing innovative techniques and unified benchmarks, professionals can ensure longer-lasting, more vibrant finishes that meet the evolving expectations of consumers. As the industry continues to adapt and refine its practices, maintaining high paint finish quality standards will be key to fostering customer satisfaction and driving industry growth.