Sensor drift in vehicles can compromise safety systems like airbag deployment and collision avoidance. Regular safety sensor recalibration is crucial to maintain accuracy against environmental factors. This process prevents false alarms, enhances performance during repair, and optimizes safety response times, adhering to manufacturer guidelines for reliable advanced driver assistance systems (ADAS).

In the realm of industrial safety, timely maintenance of safety sensors is paramount. This article guides you through the decision-making process for scheduling a professional safety sensor recalibration. Understanding sensor drift and its impact is crucial. We outline key indicators prompting recalibration and emphasize the benefits of regular calibration procedures to optimize overall safety. By adhering to these practices, ensure your facility operates efficiently while prioritizing worker protection.

- Understanding Sensor Drift and Its Impact

- When to Initiate Recalibration: Key Indicators

- Optimizing Safety with Regular Calibration Procedures

Understanding Sensor Drift and Its Impact

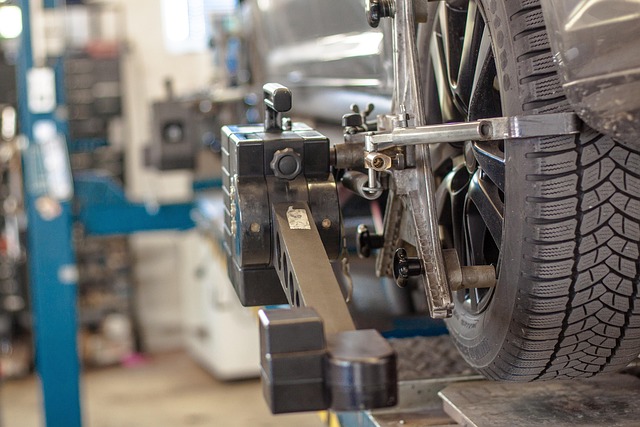

Sensor drift is a subtle yet significant issue that can impact the accuracy and reliability of safety sensors in vehicles. These sensors play a critical role in modern automotive systems, from airbag deployment to collision avoidance mechanisms. Over time, as sensors are exposed to various environmental conditions, their readings may become less precise. This phenomenon occurs due to factors like temperature fluctuations, dust accumulation, or changes in the physical properties of the sensor itself.

In the realm of automotive body work and collision repair, maintaining the integrity of safety systems is paramount. Drift in sensors can lead to false positives or negatives during critical operations, potentially endangering passengers and other road users. For example, a misaligned sensor might trigger an unnecessary airbag deployment, causing damage to the vehicle’s interior and passenger discomfort. Conversely, a faulty sensor could fail to detect an impending collision, leaving a crucial safety margin unaccounted for. Regular safety sensor recalibration is essential in mitigating these risks and ensuring optimal performance in both automotive restoration and collision repair center settings.

When to Initiate Recalibration: Key Indicators

The need for a safety sensor recalibration arises when several key indicators suggest that the system’s accuracy and reliability may be compromised. One of the primary signs is consistent false alarms, which could be caused by environmental factors like dust or changes in temperature affecting the sensor’s readings. If you notice that the safety sensors are triggering alerts unnecessarily, it’s a clear signal that recalibration is due.

Another crucial indicator is decreased performance in critical operations, such as car paint repair or dent removal processes relying on precise sensor data. In cases where the sensors fail to detect hazards effectively, leading to potential accidents or damage during procedures like paintless dent repair, it becomes imperative to realign and calibrate them immediately. Regular maintenance checks should include an evaluation of these factors to ensure optimal safety sensor performance.

Optimizing Safety with Regular Calibration Procedures

Regular safety sensor recalibration is a cornerstone of optimizing vehicle safety, especially for critical systems like collision avoidance or airbag deployment. Over time, these sensors can drift out of calibration due to various factors such as environmental changes, wear and tear, or even slight adjustments during routine repairs like car paint repair, car dent repair, or frame straightening. A professional safety sensor recalibration ensures that these life-saving systems operate at peak performance, providing the most accurate data for faster reaction times and improved outcomes in potential accidents. By adhering to manufacturer recommendations and scheduling calibrations at strategic intervals, vehicle owners can significantly enhance overall safety without compromising on the reliability of advanced driver assistance systems (ADAS).

Regularly scheduling a professional safety sensor recalibration is crucial for maintaining optimal system performance and ensuring worker safety. By understanding sensor drift, recognizing key indicators for recalibration, and adopting regular calibration procedures, facilities can minimize risks and enhance overall operational efficiency. Remember that proactive maintenance of safety sensors is a vital step in navigating the complexities of industrial environments, ultimately fostering a safer and more productive workplace.