Understanding OEM (Original Equipment Manufacturer) repair procedures is crucial for luxury vehicle owners seeking top-tier collision or maintenance services. OEM repairs guarantee genuine parts, specialized tools, and tailored techniques to preserve the vehicle's original design, performance, and value. Aftermarket repairs offer diverse options at a lower cost, using compatible parts that integrate seamlessly with existing hardware. The choice between OEM and aftermarket depends on balancing quality, affordability, and flexibility in part sourcing and execution, affecting long-term reliability.

In the realm of vehicle maintenance, understanding the nuances between Original Equipment Manufacturer (OEM) and aftermarket repair procedures is pivotal. This article delves into these distinct approaches, offering a comprehensive guide for automotive enthusiasts and professionals alike. We’ll explore the ins and outs of OEM practices, where originality and precision reign supreme, and contrast it with the diverse landscape of aftermarket options. By the end, readers will grasp the step-by-step differences, empowering informed decisions in their repair journeys.

- Understanding OEM Repair Procedures

- Exploring Aftermarket Access Options

- Comparative Analysis: Step-by-Step Differences

Understanding OEM Repair Procedures

Understanding OEM Repair Procedures involves grasping the original equipment manufacturer’s (OEM) specific methods and parts for repairing vehicles. OEM repair procedures are designed to ensure that every aspect of the collision or maintenance process aligns with the vehicle’s original design and performance standards. This meticulous approach utilizes genuine OEM parts, specialized tools, and techniques that are tailored to the make and model of the vehicle.

For luxury vehicle owners, understanding these procedures is crucial when visiting an auto collision center. While aftermarket parts can be cost-effective, OEM repairs guarantee a seamless fit, superior quality, and optimal performance—essential considerations for maintaining the integrity and value of high-end automobiles.

Exploring Aftermarket Access Options

When considering repairs for your vehicle, understanding the distinction between OEM (Original Equipment Manufacturer) and aftermarket access options is crucial. Aftermarket repair procedures offer a wide array of choices for drivers seeking cost-effective solutions without compromising quality. These alternatives cater to various needs, from simple auto glass replacement to intricate dent repairs.

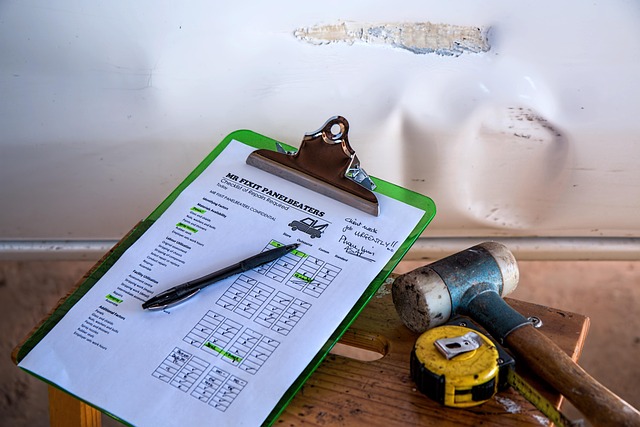

Aftermarket providers specialize in creating compatible parts that fit seamlessly with your vehicle’s existing hardware. For instance, their expertise in car dent repair ensures precise restoration, restoring the vehicle’s original appearance. Unlike OEM parts, which can be more expensive, aftermarket options often provide a balance between affordability and reliability, making them an attractive choice for budget-conscious consumers.

Comparative Analysis: Step-by-Step Differences

When comparing an OEM (Original Equipment Manufacturer) repair procedure access with an aftermarket option for a car repair shop, several distinct steps come into play. For instance, in an OEM process, the mechanic starts by acquiring genuine replacement parts directly from the vehicle manufacturer, ensuring compatibility and superior quality. This involves meticulous disassembly and reassembly of specific components, requiring specialized tools and extensive knowledge of the car’s intricate systems. In contrast, aftermarket repairs offer a more flexible approach where generic, often less expensive, parts are used. These parts might not be manufactured to the exact specifications of the original equipment but can still provide functional solutions for minor issues like a vehicle dent repair or hail damage repair.

The step-by-step differences become clearer in the execution phase. In an OEM repair, precision is paramount; each step must be executed with care to maintain the car’s overall performance and aesthetic value. Aftermarket repairs, while still adhering to safety standards, may take a more cost-effective route by employing different techniques for specific tasks, such as using specialized tools for hail damage repair or innovative methods for removing vehicle dents. These variations in procedure access can significantly impact the final outcome, with OEM potentially offering a more seamless return to pre-damage conditions, while aftermarket repairs might present slight deviations that are often invisible to the untrained eye but may affect long-term reliability.

When comparing OEM (Original Equipment Manufacturer) and aftermarket repair procedures, understanding the nuances in access is key. While OEM methods adhere strictly to the manufacturer’s guidelines, ensuring a precise, factory-like fix, aftermarkets offer enhanced flexibility and choices for repairs. The latter’s accessibility and cost-effectiveness make it an attractive option, though it may require more adaptability from the technician. This analysis highlights the distinct steps and considerations, empowering individuals to choose the repair path best suited to their needs, be it preserving original specifications or exploring alternative solutions.