Electric and hybrid vehicles' unique design poses challenges for frame damage repairs, requiring specialized tools like robotic welding systems and CAD software. Advanced frame repair technologies, including 3D printing and paintless dent repair methods, streamline repairs, reduce waste, and minimize downtime, enhancing sustainability and longevity. Future trends focus on eco-friendly practices, lighter materials, and digital technologies for precise, efficient, and cost-effective solutions.

In the rapidly evolving automotive industry, electric and hybrid vehicles (EVs) are gaining popularity due to their environmental benefits. However, these advanced vehicles present unique challenges in frame repair, as their complex designs and lightweight materials differ significantly from traditional internal combustion engines. This article explores cutting-edge frame repair technology tailored for EVs, focusing on understanding frame damage, advanced repair methods, and the future of sustainable and innovative solutions that redefine the landscape of vehicle maintenance.

- Understanding Frame Damage in Electric Vehicles

- Advanced Technologies for Efficient Repairs

- The Future of Frame Repair: Sustainability and Innovation

Understanding Frame Damage in Electric Vehicles

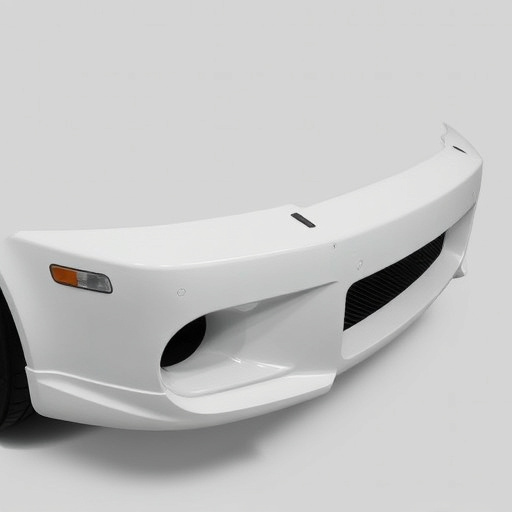

Electric and hybrid vehicles have revolutionized the automotive industry, but with their intricate design and lightweight construction comes unique challenges when it comes to frame damage. Unlike traditional internal combustion engine vehicles, electric cars often have a more compact and modular structure, making frame repairs more complex. A simple fender bender or side-impact collision can potentially affect crucial components like battery packs, motor units, and power electronics housed within the vehicle’s chassis.

Proper understanding of frame damage in these vehicles is essential for efficient frame repair technology. Auto body repair specialists need to be adept at identifying hidden damage, as even minor impacts can compromise structural integrity. Collision repair services for electric vehicles require specialized tools and techniques to safely disassemble and reassemble specific sections without affecting sensitive parts. Automotive body work on these advanced vehicles demands precision and adherence to stringent safety standards to ensure optimal performance and reliability after the repair process.

Advanced Technologies for Efficient Repairs

The advancement of frame repair technology has revolutionized both electric and hybrid vehicle maintenance. Modern methods go beyond traditional autobody repairs, employing advanced techniques tailored to the unique challenges posed by these innovative vehicles. For instance, robotic welding systems offer precision and consistency, ensuring structural integrity during repairs, a critical aspect for safety and performance.

Additionally, computer-aided design (CAD) software and 3D printing have integrated into auto body services, enabling technicians to create replacement parts with exact specifications. This technology streamlines the repair process, minimizing waste and downtime, which is particularly beneficial for electric vehicles, where battery positioning and packaging are complex. As a result, these advanced frame repair technologies not only enhance the efficiency of repairs but also contribute to the overall sustainability and longevity of electric and hybrid vehicles.

The Future of Frame Repair: Sustainability and Innovation

The future of frame repair for electric and hybrid vehicles is being shaped by a dual focus on sustainability and innovation. As the demand for eco-friendly transportation continues to grow, so does the need for advanced frame repair technologies that minimize environmental impact. Modern methods like paintless dent repair are gaining traction due to their reduced use of harmful chemicals and lower energy consumption compared to traditional auto body repair techniques.

This shift towards sustainability is complemented by rapid technological advancements. Innovations in materials science are leading to lighter, stronger, and more durable frames, reducing the overall weight of vehicles and thereby enhancing fuel efficiency. Additionally, digital technologies such as 3D printing and robotics are transforming auto body repair by enabling precise, efficient, and cost-effective frame repairs. These developments promise a greener and smarter future for vehicle maintenance, ensuring that both performance and environmental responsibility go hand in hand.

Frame repair technology for electric and hybrid vehicles is revolutionizing the automotive industry, offering efficient solutions for damage that was once considered challenging. By leveraging advanced techniques and materials, today’s repairs are not only stronger but also more sustainable, aligning with the eco-friendly ethos of these vehicles. As research continues, we can expect even more innovative frame repair technologies to emerge, further enhancing safety, performance, and environmental friendliness in the future.