Precision frame alignment is a critical process in automotive repair, ensuring structural integrity and safety by meticulously adjusting vehicle frames to factory specifications post-accidents. For high-end shops like those specializing in Mercedes Benz, diagnostic reports with measurable data and visual aids are essential tools to guide this meticulous procedure. Regular equipment calibration and robust quality control measures guarantee accurate measurements and optimal precision frame alignment, crucial for maintaining vehicle performance, handling, and safety during services like tire replacements or collision repairs.

Precision Frame Alignment (PFA) is a critical process ensuring accurate positioning and orientation of frames in construction projects. To guarantee optimal performance, diagnostic reports play a pivotal role in verifying PFA results. This article explores the importance of PFA verification through diagnostic assessments, delving into the benefits, methods, and best practices to ensure reliable outcomes. By understanding these key aspects, professionals can maintain high standards throughout their projects.

- Understanding Precision Frame Alignment

- The Role of Diagnostic Reports in Verification

- Best Practices for Ensuring Accurate Results

Understanding Precision Frame Alignment

Precision frame alignment is a critical process in automotive repair, ensuring that a vehicle’s structure is accurately adjusted after an accident or collision. It involves meticulously realigning the car’s metal panels, columns, and other components to their original factory specifications. This meticulous procedure is essential for maintaining the structural integrity of the vehicle, as well as its safety and handling capabilities.

Proper precision frame alignment is particularly crucial when it comes to auto detailing and collision repair services. For instance, during a car dent repair process, aligning the affected areas with precision ensures that the repairs are not only visually appealing but also structurally sound. This attention to detail can prevent future issues and ensure the vehicle’s longevity on the road, much like how a symphony relies on each instrument playing in perfect harmony for a beautiful performance.

The Role of Diagnostic Reports in Verification

Diagnostic reports play a pivotal role in verifying precision frame alignment for vehicles, especially in high-end automotive brands like Mercedes Benz repair shops. These detailed reports act as a benchmark, ensuring that each vehicle’s frame is aligned to exacting standards. By providing measurable data and visual representations, diagnostic tools enable technicians to identify even the subtlest misalignments.

For instance, in tire services or collision repair services, accurate frame alignment is crucial for maintaining vehicle safety and performance. Diagnostic reports help in comparing pre and post-repair measurements, allowing experts to assess the effectiveness of the alignment process. This meticulous approach guarantees that vehicles, after repairs or maintenance, drive smoothly, handle precisely, and meet manufacturer specifications—a key aspect in keeping up with modern automotive demands.

Best Practices for Ensuring Accurate Results

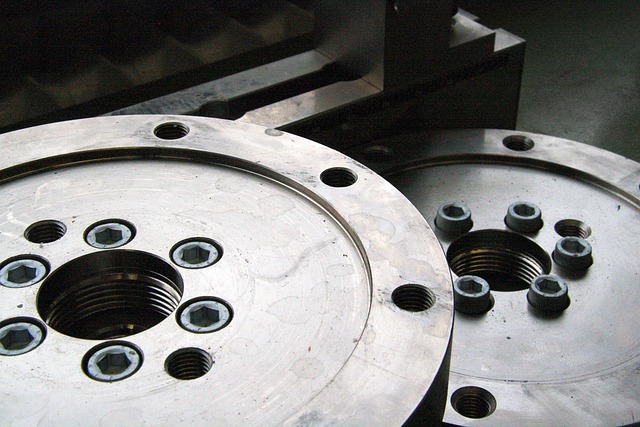

To achieve reliable results with precision frame alignment, several best practices should be followed. Firstly, ensure that all equipment used for measurement and adjustment is calibrated regularly and maintained in optimal condition. This includes laser sensors, alignment tools, and any other technology employed in the process. Regular calibration ensures accurate readings, which directly impacts the final alignment’s precision.

Secondly, adhere to strict quality control measures during every step of the frame alignment procedure. This involves double-checking measurements, cross-referencing data from diagnostic reports, and verifying adjustments before proceeding. Vehicle paint repair and auto body repair professionals should also consider using advanced software that provides real-time feedback and alerts for any deviations or potential issues, enhancing overall accuracy in auto maintenance tasks.

Precision frame alignment is a critical process that demands meticulous attention and verification. Diagnostic reports play a pivotal role in ensuring the accuracy of these alignments, providing valuable insights into potential issues or discrepancies. By adhering to best practices and incorporating diagnostic reports, professionals can maintain optimal precision frame alignment, ultimately enhancing the overall quality and reliability of their work.