Metal finishing techniques, including coating, plating, painting, and sealing, enhance automotive components' appearance and longevity. Processes like electrostatic powder coating reduce repaint needs and repair costs, influencing auto body panel replacements' quality and consistency. Cost dynamics vary with methods like machine polishing vs. sandblasting, impacting luxury vehicle repairs. Strategically selecting metal finishing aligns aesthetic appeal with cost-effectiveness, considering project requirements, durability, and resale value. Alternatives like powder coating and electroplating, along with sustainable options, further optimize repair costs.

Metal finishing is a critical process that can significantly impact repair costs in various industries. This article delves into the intricate world of metal finishing techniques and their profound effects on overall repair expenses. From understanding different finishing methods and their unique advantages to conducting a thorough cost analysis, we explore strategies to optimize repair costs. Additionally, discover best practices for selecting the most suitable metal finishing technique, ensuring efficient and cost-effective repairs without compromising quality.

- Understanding Metal Finishing Techniques and Their Impact

- Cost Analysis: How Metal Finishing Affects Repair Expenses

- Optimizing Repair Costs: Best Practices for Metal Finishing Selection

Understanding Metal Finishing Techniques and Their Impact

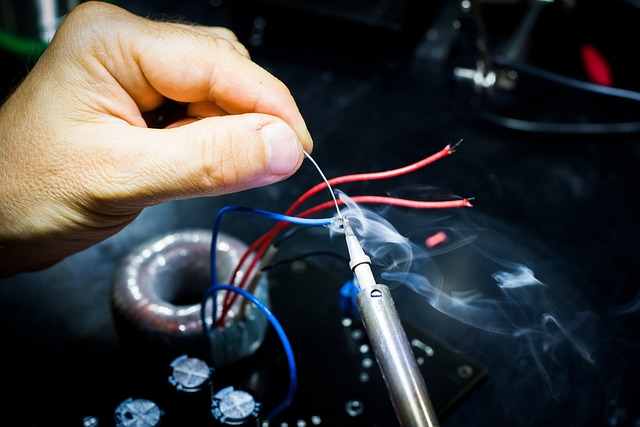

Metal finishing techniques play a pivotal role in shaping the final aesthetic and durability of metal components, especially in the automotive industry. These processes involve various methods like coating, plating, painting, or sealing to enhance the surface properties of metal parts. Each technique offers unique advantages, from improving corrosion resistance and enhancing aesthetics to extending the lifespan of repair work. For instance, electrostatic powder coating is a popular choice for auto body panels, providing a durable, chip-resistant finish that can significantly reduce repaint needs during an automotive collision repair.

Understanding these finishing techniques is crucial when considering overall repair costs. At your local auto repair near me or fleet repair services, technicians employ different metal finishing approaches based on vehicle requirements and desired outcomes. Efficient application of these methods not only reduces the need for frequent touch-ups but also ensures that repaired parts match the original manufacturer’s standards, minimizing visual discrepancies in case of replacement. By selecting appropriate metal finishing techniques, repair shops can offer high-quality services while optimizing labor and material costs, making it a key strategic decision in the automotive aftercare industry.

Cost Analysis: How Metal Finishing Affects Repair Expenses

The process of metal finishing plays a significant role in determining the overall costs of repairs, especially in sectors like automotive restoration and luxury vehicle repair. When considering a vehicle restoration project, the quality and method of metal finishing can dramatically impact the final expense. For instance, intricate scratch repair on a high-end car may require more advanced techniques such as machine polishing or hand buffing, which can increase costs compared to straightforward sandblasting methods.

Different metal finishing processes have varying levels of labor intensity and material consumption. Simple coatings or paints might be less expensive but offer lesser durability and aesthetic appeal. Conversely, specialized finishes like galvanizing or custom plating not only add visual value but also extend the life of the vehicle’s exterior, potentially reducing long-term repair costs. Understanding these dynamics is crucial for both consumers and service providers in the luxury vehicle repair niche, as it enables informed decisions that can balance aesthetics, functionality, and budget.

Optimizing Repair Costs: Best Practices for Metal Finishing Selection

Optimizing repair costs through strategic metal finishing selection is a key consideration for any automotive service center. By understanding the diverse range of finishes available and their specific applications, shops can offer tailored solutions that balance aesthetic appeal with cost-effectiveness. For instance, while luxurious auto painting with high-end finishes may be suitable for luxury vehicle repair, it might not be necessary or budget-friendly for routine auto maintenance.

Best practices dictate evaluating project requirements, material durability, and future resale value before choosing a finish. Exploring alternatives like powder coating, electroplating, or even innovative sustainable options can also significantly impact overall repair costs. By adopting these strategies, automotive professionals can ensure their metal finishing choices align with both customer expectations and budgetary constraints.

Metal finishing plays a pivotal role in managing repair costs. By understanding different techniques and their impact, you can make informed decisions that optimize expenses. A cost analysis reveals how strategic choices in metal finishing can significantly reduce overall repair bills. Implementing best practices ensures efficient selection, leading to durable and aesthetically pleasing results without breaking the bank. Embracing these practices is a step towards revolutionizing repair processes in today’s competitive market.