Mercedes-Benz has adopted advanced factory welding methods using laser hybrid technology for enhanced structural integrity, streamlined production, and improved quality control, addressing industry challenges while ensuring robust, reliable vehicles and superior collision damage repair services. This innovative approach positions Mercedes at the forefront of automotive manufacturing, setting new standards in efficiency and vehicle quality.

Mercedes-Benz, renowned for its luxury and innovation, employs cutting-edge welding technologies in its factory. Among these, Laser Hybrid Welding stands out as a game-changer. This revolutionary method combines the precision of laser welding with the strength of traditional hybrid techniques, enhancing structural integrity while streamlining production. By delving into Mercedes’ advanced welding practices, we uncover how this technology is shaping the future of automotive assembly, promising faster, more efficient, and safer vehicles.

- Exploring Mercedes' Advanced Welding Techniques

- Laser Hybrid Welding: Revolutionizing Production

- The Future of Automotive Assembly: A Look Inside

Exploring Mercedes' Advanced Welding Techniques

Mercedes-Benz, renowned for its luxury and precision engineering, has consistently pushed the boundaries of automotive innovation, including in the realm of factory welding methods. The German automaker has embraced advanced technologies to enhance structural integrity while streamlining production processes. One such game-changer is laser hybrid welding, a technique that combines the precision of laser welding with the speed of conventional methods, making it ideal for high-volume car manufacturing. This method not only improves overall efficiency but also contributes to reduced emissions and faster vehicle repair services, addressing contemporary challenges in the automotive industry.

By integrating cutting-edge welding technologies, Mercedes ensures that every vehicle undergoes rigorous quality checks during production, minimizing the occurrence of defects often associated with car collision repair or hail damage repair. The automaker’s commitment to innovation translates into robust and reliable vehicles, ensuring customer satisfaction and safety on the road. This focus on advanced manufacturing processes sets a benchmark for the industry, demonstrating Mercedes’ unwavering dedication to delivering exceptional vehicle repair services while adhering to stringent quality standards.

Laser Hybrid Welding: Revolutionizing Production

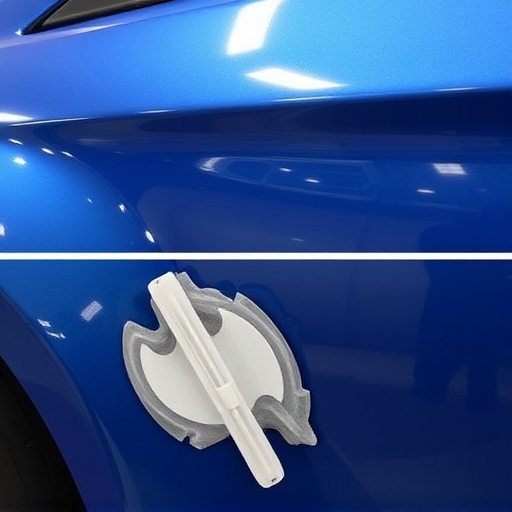

Mercedes factory welding methods have seen a significant evolution with the advent of Laser Hybrid Welding technology. This cutting-edge approach combines the precision and speed of laser welding with the strength and efficiency of traditional hybrid welding techniques. The result is a revolutionary process that streamlines production, enhances quality control, and reduces waste—all critical factors in modern automotive manufacturing.

By integrating this advanced welding method, Mercedes not only ensures superior structural integrity for their vehicles but also optimizes the overall car body repair process. This includes minimizing collision damage repair time and improving the accuracy of auto collision center operations. The Laser Hybrid Welding technology is a game-changer, setting new standards in both production efficiency and vehicle quality, reflecting Mercedes’ commitment to innovation and excellence across all facets of their manufacturing processes.

The Future of Automotive Assembly: A Look Inside

The future of automotive assembly is here, and it’s powered by cutting-edge technology like laser hybrid welding. At Mercedes factories, this innovative method sets a new standard for precision and efficiency in manufacturing. By combining the accuracy of lasers with the strength of traditional welding techniques, Mercedes ensures that every vehicle produced meets the highest quality standards. This advanced approach not only streamlines production but also contributes to the overall durability and reliability of their vehicles.

Looking ahead, as the automotive industry continues to evolve, we can expect more manufacturers to adopt similar strategies. The adoption of laser hybrid welding and other modern techniques in auto repair shops and manufacturing facilities worldwide signals a promising future for both the industry and consumers. These advancements in Mercedes factory welding methods suggest a new era of seamless automotive body work, where efficiency meets excellence, ultimately driving the industry forward.

Mercedes has pioneered innovative Mercedes factory welding methods, particularly with its adoption of laser hybrid welding technology. This cutting-edge approach not only enhances structural integrity but also streamlines production, making automotive assembly more efficient and precise. As the industry continues to evolve, Mercedes factory welding methods like these will likely set the standard for future advancements in automotive manufacturing.