The vehicle body repair industry is rapidly adopting eco-friendly practices and innovative technologies to reduce its environmental impact. By using recycled and biodegradable materials like bio-based composites and reclaimed metal, shops can minimize waste and pollution. Automated welding systems offer more efficient, less resource-intensive methods that further reduce energy consumption and emissions. Additionally, recycling programs encourage waste reduction and proper disposal of hazardous substances, promoting sustainability without compromising safety, durability, or quality in Mercedes Benz repair and other vehicle body repairs.

The vehicle body repair industry is undergoing a significant transformation as environmental best practices become increasingly vital. This article explores sustainable strategies that are not only eco-friendly but also economically sound for this sector. We delve into adopting sustainable materials and processes, such as exploring eco-friendly alternatives and implementing recycling programs. Additionally, we discuss efficient energy management techniques, including renewable energy adoption and heat recovery systems, and the role of digitalization in waste reduction and proper disposal of hazardous materials.

- Adopting Sustainable Materials and Processes

- – Exploring eco-friendly alternatives for body panels and repair materials

- – Implementing recycling programs for waste reduction

Adopting Sustainable Materials and Processes

The vehicle body repair industry is undergoing a significant transformation as businesses embrace sustainable practices and materials to reduce their environmental impact. One of the key aspects in this shift is the adoption of eco-friendly solutions that minimize waste and pollution associated with traditional car body restoration techniques. By incorporating recycled and biodegradable materials, such as bio-based composites or reclaimed metal, repair shops can create more environmentally conscious processes. For instance, using bio-resins in composite repairs reduces the carbon footprint compared to conventional synthetic resins, contributing to a greener car restoration process.

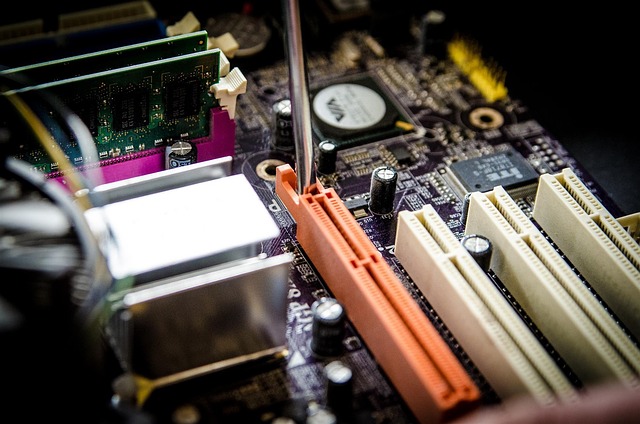

Additionally, implementing innovative technologies allows for more efficient and less resource-intensive methods. Automated welding systems, for example, can reduce energy consumption and minimize the release of harmful emissions during Mercedes Benz repair or any other vehicle body repair processes. These advancements not only support sustainable practices but also lead to improved quality and precision in car restoration, ensuring a balance between environmental stewardship and exceptional craftsmanship.

– Exploring eco-friendly alternatives for body panels and repair materials

The vehicle body repair industry is undergoing a significant transformation as awareness of environmental sustainability grows. One key area of focus is exploring eco-friendly alternatives for body panels and repair materials. Traditional methods often rely on heavy metals and toxic chemicals, contributing to environmental pollution and waste. However, innovative solutions are emerging, such as the use of lightweight, recycled materials like plant-based composites and bio-polymers, which can reduce the carbon footprint associated with vehicle bodywork.

These alternative materials not only offer ecological benefits but also enhance safety and durability. For instance, advanced car paint repair techniques now incorporate low-VOC (volatile organic compound) paints and water-based coatings, minimizing air pollution during the repair process. Similarly, car scratch repair methods have evolved to include non-toxic, fast-drying polishes made from natural ingredients, ensuring a greener approach without compromising on quality or performance.

– Implementing recycling programs for waste reduction

In the vehicle body repair industry, implementing recycling programs is a significant step towards minimizing environmental impact and fostering sustainability. By adopting practices that promote waste reduction, auto bodywork professionals can play a crucial role in preserving natural resources. One effective strategy involves sorting and reusing materials from damaged vehicles, such as metal, plastic, and glass components. These materials can be remanufactured into new products, thereby decreasing the demand for virgin resources and reducing landfill waste.

Moreover, efficient recycling programs in auto body shops can extend to the management of hazardous substances commonly found in vehicles, like old fluids and batteries. Proper disposal methods ensure these materials are recycled or treated safely, preventing pollution and environmental degradation. Such initiatives not only contribute to a greener image for vehicle repair services but also encourage a more sustainable approach within the industry as a whole.

The vehicle body repair industry has a significant opportunity to reduce its environmental impact by adopting sustainable practices. By exploring eco-friendly alternatives to traditional materials and processes, such as using recycled content for body panels and implementing efficient recycling programs for waste, the sector can play a crucial role in minimizing its carbon footprint. These best practices not only benefit the environment but also contribute to a more responsible and future-proof industry, ensuring a greener landscape in vehicle body repair.