Metal fabrication collision repairs are an art combining traditional and advanced techniques to restore and enhance damaged metal components, ensuring structural integrity and aesthetic appeal. Modern methods like paintless dent repair (PDR), robotic welding, and laser metal fusion cater to diverse needs, offering invisible fixes, precise welds, and accurate repairs. Skilled technicians use high-tech equipment for exact replicates of original parts, maintaining safety and vehicles' original appearance through meticulous removal, scanning, and reconstruction.

In the realm of automotive restoration, metal fabrication collision repairs stand out as intricate processes demanding precision and expertise. This article delves into the advanced techniques shaping the future of collision repair, specifically focusing on metal fabrication. We explore the intricacies of understanding collision damage, employing sophisticated methods for complex repairs, and upholding quality standards. By mastering these techniques, professionals ensure vehicles not only look like new but also maintain structural integrity, highlighting the synergy between art and science in metal fabrication collision repairs.

- Understanding Metal Fabrication Collision Repairs

- Advanced Techniques for Complex Repairs

- Ensuring Quality and Precision in Collision Repair

Understanding Metal Fabrication Collision Repairs

Metal fabrication collision repairs are a specialized process that involves restoring damaged metal components to their original condition or even enhancing them for improved performance. This intricate art requires a deep understanding of metal properties, various fabrication techniques, and precise measurement to ensure structural integrity and aesthetic appeal. The goal is to fix not just the visible damage but also to maintain or improve the overall quality of the metal parts.

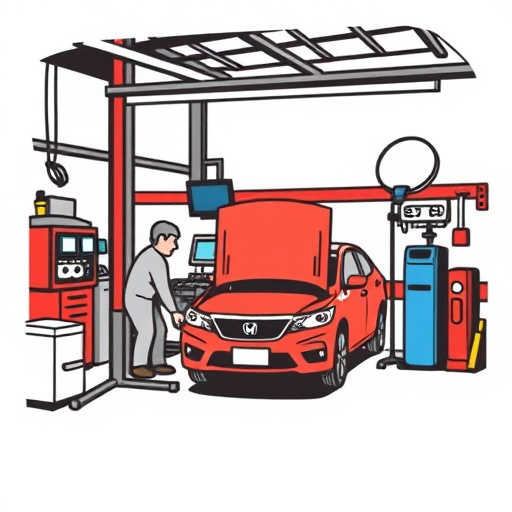

In an auto repair shop, vehicle collision repair is a common scenario where metal fabrication skills are put to the test. Vehicle paint repair, for instance, demands meticulous attention to detail as technicians must carefully remove damaged paint, patch and smooth the surface, then expertly reapply new paint to match the original finish. This process not only involves repairing the physical damage but also ensures the vehicle retains its pre-collision aesthetics, enhancing its overall value and resale potential in the market.

Advanced Techniques for Complex Repairs

In the realm of advanced metal fabrication collision repairs, modern technologies have significantly enhanced the scope and precision of restoration work. Techniques like paintless dent repair (PDR) have revolutionized the industry by offering nearly invisible mend to damaged vehicle bodies, preserving not just the structural integrity but also the original aesthetics. This non-invasive approach involves specialized tools and techniques to push out dents from the inside without damaging the surrounding paintwork, making it ideal for both minor and complex repairs.

For more intricate scenarios, advanced technologies such as robotic welding systems and laser metal fusion are employed. Robotic arms equipped with precise sensors enable consistent and calculated welds, crucial for aligning bent or damaged panels back to their original shape. Meanwhile, vehicle dent repair and scratch repair processes benefit from laser technology that can melt and fuse metal with remarkable accuracy, enabling the reconstruction of contorted bodies and restoration of scratches at a microscopic level. These advanced techniques not only ensure structural integrity but also deliver a flawless finish, catering to the demanding needs of modern automotive repairs.

Ensuring Quality and Precision in Collision Repair

In the realm of advanced metal fabrication collision repairs, achieving precision and quality is paramount to ensure the safety and aesthetics of vehicles. Skilled technicians employ a combination of traditional and innovative techniques to meticulously address damage, from cracked fenders to severely bent frames. High-tech equipment like robotic welders and 3D printing machines play a crucial role in this process, enabling precise measurements and exact replicates of original parts.

Moreover, meticulous attention is dedicated to every detail during the collision repair process. This includes careful removal of damaged components, accurate measurement using advanced scanning technologies, and precise reconstruction. Following these stringent protocols guarantees that repairs not only restore structural integrity but also maintain the vehicle’s original appearance, including expert auto body repair, flawless bumper restoration, and seamless auto painting.

In the realm of advanced metal fabrication collision repairs, understanding the intricacies of these processes is key. By employing sophisticated techniques such as laser welding and computer-aided design (CAD), repair professionals can achieve remarkable results in complex cases. Maintaining quality and precision is paramount to ensure the structural integrity and longevity of vehicles post-repairs. As the automotive industry continues to evolve, adopting these cutting-edge methods ensures that metal fabrication collision repairs meet the highest standards, providing safe and reliable transportation for all.