Tesla structural repair training is crucial for specialized technicians to handle unique aluminum materials, high-voltage systems, and intricate panel work safely. Adhering to strict guidelines, this training focuses on hazard recognition, advanced tools, and meticulous detail to ensure top-quality, safe repairs for Tesla models, preserving their performance and aesthetic appeal.

Tesla vehicles are known for their cutting-edge technology, but proper structural repair and high-voltage safety protocols are essential for maintaining their performance. This article delves into the critical areas of Tesla structural repair training and safety measures. We explore the unique requirements for repairing Tesla vehicles, focusing on comprehensive high-voltage safety training. By understanding best practices and safe protocols, technicians can ensure optimal results while safeguarding against potential hazards associated with electric vehicle repairs.

- Understanding Tesla Structural Repair Requirements

- Comprehensive High-Voltage Safety Training

- Best Practices for Safe Repair Protocols

Understanding Tesla Structural Repair Requirements

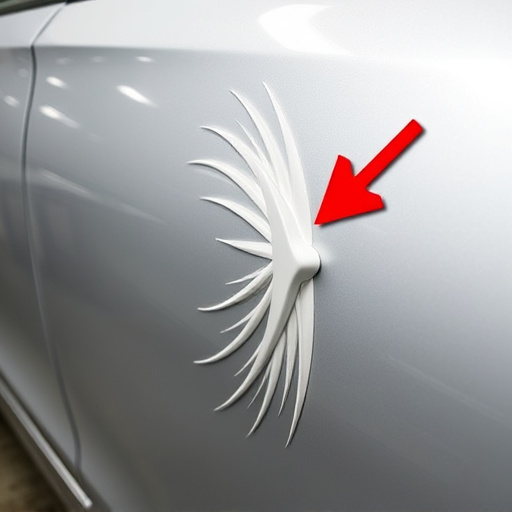

In the realm of automotive repair, Tesla structural repair stands out as a specialized field requiring meticulous attention to detail and adherence to stringent safety protocols. Understanding Tesla’s unique structural design and high-voltage systems is paramount for any collision repair shop aiming to provide top-notch services. The brand’s electric vehicles (EVs) incorporate advanced aluminum and lightweight materials, necessitating specific training for technicians in Tesla structural repair.

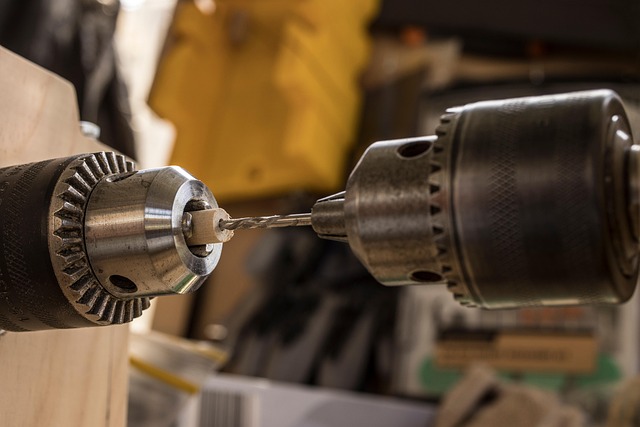

This specialized training equips professionals with the knowledge to handle intricate panel replacement, body alignment, and frame straightening procedures while ensuring the integrity of high-voltage components. Given that Tesla vehicles are equipped with powerful batteries and advanced electric motors, collision repair shops must prioritize safety measures. Training programs focus on recognizing potential hazards, implementing proper handling techniques, and employing cutting-edge tools to perform vehicle collision repair without compromising the safety of both technicians and the environment. This comprehensive approach ensures that any Mercedes Benz collision repair or that of other Tesla models is executed with precision and adherence to high-voltage safety protocols.

Comprehensive High-Voltage Safety Training

In the realm of Tesla structural repair training, comprehensive high-voltage safety protocols are paramount. Professionals in this field must undergo rigorous education to understand and manage the intricate electrical systems within Tesla vehicles. This training equips them with the knowledge to handle high-voltage components safely, ensuring that any repairs or modifications are conducted without compromising the vehicle’s integrity or the well-being of technicians.

With the growing demand for auto body services catering specifically to electric vehicles, automotive repair services focused on Tesla structural repair have become indispensable. Car body shops specializing in this area not only offer top-notch repairs but also adhere to stringent safety guidelines, making them key players in maintaining the performance and safety of these advanced vehicles.

Best Practices for Safe Repair Protocols

When engaging in Tesla structural repair training, adhering to best practices for safe repair protocols is paramount. This includes donning appropriate personal protective equipment (PPE), such as insulated gloves and safety glasses, to mitigate risks associated with high-voltage systems. Specialized tools designed for electric vehicle (EV) repairs should be utilized, ensuring precision and minimizing the potential for short circuits or electrical faults. Proper ventilation is another critical aspect, especially when dealing with certain materials used in Tesla construction.

For luxury vehicle repair specialists, understanding that each Tesla model may have unique structural nuances is essential. This requires ongoing training to stay updated on the latest repairs and safety protocols. Even common tasks like auto glass replacement or scratch repair demand meticulous attention to detail to preserve the vehicle’s integrity and aesthetic appeal. Following these best practices not only ensures the safety of technicians but also guarantees that the Tesla remains in optimal condition after any repair work is completed.

Tesla structural repair training and adherence to high-voltage safety protocols are paramount in ensuring the integrity of electric vehicle repairs. By mastering these skills, technicians can confidently navigate complex procedures while prioritizing safety. This comprehensive guide equips professionals with the knowledge to meet Tesla’s stringent standards, ultimately fostering a secure and reliable repair environment for this cutting-edge automotive technology.