Carbon fiber repair methods in autos address unique challenges posed by its strength and fragility. Non-welding techniques, using specialized adhesives and composite materials, offer speed, precision, and cost savings over traditional welding. These advanced methods enhance efficiency, minimize material waste, and restore vehicles to high-quality standards at lower costs.

Carbon fiber components are increasingly common in modern vehicles, aircraft, and sports equipment due to their exceptional strength-to-weight ratio. However, damage to these complex materials can be costly to repair using traditional methods. This article explores how advanced carbon fiber repair methods significantly reduce repair costs by efficiently addressing damage without the need for intensive welding processes. We’ll delve into understanding common carbon fiber damage and the advantages of modern non-welding techniques over conventional approaches.

- Understanding Carbon Fiber Damage and Its Impact on Costs

- Exploring Non-Welding Repair Techniques for Efficiency

- Advantages of Advanced Carbon Fiber Repair Methods Over Traditional Approaches

Understanding Carbon Fiber Damage and Its Impact on Costs

Carbon fiber, a lightweight and durable material widely used in modern automotive construction, offers exceptional strength-to-weight ratios. However, its unique properties also make it prone to specific types of damage. Cracks, delaminations, and fiber separation can occur due to impact events, poor manufacturing processes, or environmental factors like UV exposure. These damages not only compromise the structural integrity of components but also significantly impact repair costs for vehicle owners.

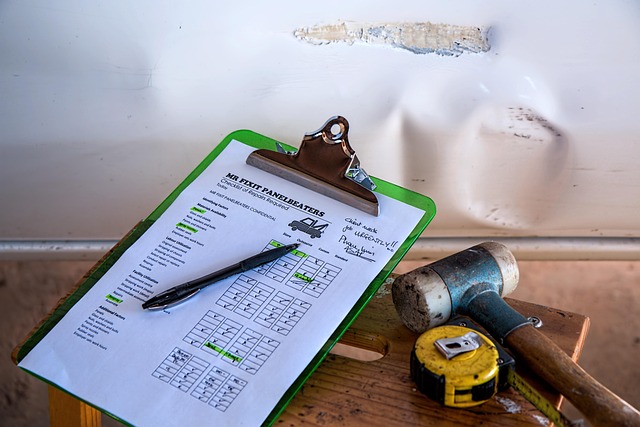

In the realm of car bodywork services, addressing carbon fiber damage often requires specialized techniques and materials. Simple repairs might involve filling small cracks with composite resins, while more complex delaminations may necessitate full-scale replacement and reglueing of affected sections. Auto glass replacement is another consideration if the damage extends to window frames or components reinforced with carbon fiber. Vehicle restoration enthusiasts who tackle these issues themselves can reduce costs by utilizing appropriate carbon fiber repair methods, ensuring long-lasting results for their efforts.

Exploring Non-Welding Repair Techniques for Efficiency

In the realm of automotive repairs, especially with high-end vehicles equipped with carbon fiber bodies, exploring efficient and cost-effective solutions is paramount. Traditional welding methods for carbon fiber repair can be time-consuming and may not always guarantee structural integrity. Thus, many vehicle repair services are now adopting non-welding repair techniques that offer significant advantages in terms of speed, precision, and cost savings. These advanced carbon fiber repair methods allow specialists to address damaged panels, cracks, or dents without the need for intensive welding processes.

This shift towards innovative approaches has revolutionized auto glass repair and vehicle paint repair techniques. By utilizing specialized adhesives, composite materials, and automated repair equipment, technicians can restore carbon fiber surfaces to their original condition at a fraction of the time and cost associated with traditional methods. As a result, vehicle owners benefit from faster turnaround times, reduced labor costs, and minimal disruption to their daily commutes, ensuring that their high-performance vehicles remain both reliable and aesthetically pleasing.

Advantages of Advanced Carbon Fiber Repair Methods Over Traditional Approaches

Advanced carbon fiber repair methods offer significant advantages over traditional approaches when it comes to cost-effectiveness and efficiency. These modern techniques are designed to handle complex repairs with precision, ensuring minimal material waste and optimized use of resources. By employing specialized tools and trained technicians, automotive body shops can now effectively mend damaged carbon fiber components, maintaining the structural integrity and aesthetic appeal of vehicles.

Unlike conventional collision repair processes, advanced carbon fiber repair involves less labor-intensive work, reducing overall repair costs. The use of cutting-edge technology, such as 3D scanning and computer-aided design (CAD), allows for accurate measurements and precise repairs, eliminating the need for extensive rework. This, in turn, saves time and money while ensuring that the vehicle returns to its original condition or even surpasses it in terms of appearance. As a result, car owners benefit from cost-efficient solutions without compromising on the quality of their vehicles, making advanced carbon fiber repair methods a preferred choice for modern automotive body shops.

Carbon fiber repair methods have evolved significantly, offering cost-effective solutions for damage previously requiring expensive welding. By exploring non-welding techniques and advanced repair approaches, professionals can reduce labor costs and minimize material waste. These innovative methods not only enhance the efficiency of repairs but also ensure structural integrity, preserving the performance and value of carbon fiber components. Adopting these modern repair practices is a step towards making carbon fiber maintenance more accessible and affordable while maintaining high-quality standards.