Plastic welding technology has revolutionized vehicle repair, offering a sleek, durable alternative to traditional methods, enhancing aesthetic appeal and streamlining repairs with precision and speed, ideal for intricate bodywork and modern plastic body panels, making it essential for auto repair, fleet maintenance, and collision centers.

Plastic welding technology has emerged as a game-changer in vehicle repairs, revolutionizing car restoration and auto body work. This innovative process offers precise, durable, and aesthetically pleasing solutions for repairing and replacing plastic components in cars. With its ability to mimic the original material’s properties, plastic welding provides numerous benefits, including cost savings, faster repair times, and enhanced structural integrity. This article explores the impact of this technology on modern auto repair practices.

- Revolutionizing Vehicle Repairs: Plastic Welding Technology

- Benefits of Using Plastic Welding for Car Restoration

- The Role of Plastic Welding in Modern Auto Body Repair

Revolutionizing Vehicle Repairs: Plastic Welding Technology

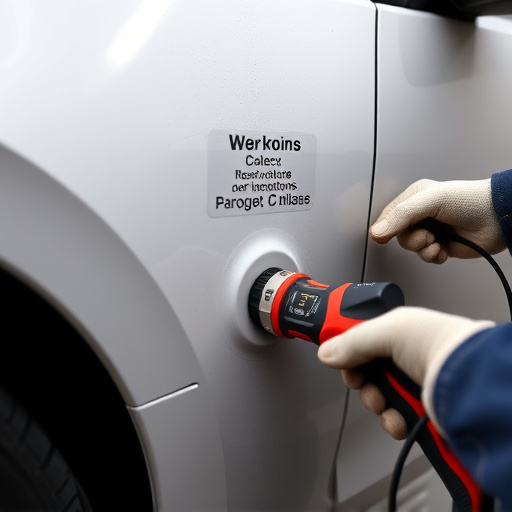

Plastic welding technology has revolutionized vehicle repairs, offering a game-changing solution for automotive body work. In today’s digital era, the demand for efficient and durable repair methods is higher than ever. Traditional methods often leave remnants of their process, from moisture in paint jobs to visible seams in car bodywork. However, plastic welding technology provides a seamless finish, nearly indistinguishable from the original car body, ensuring both aesthetic appeal and structural integrity.

This innovative approach not only enhances the quality of tire services but also streamlines repair processes. By reducing the need for complex and time-consuming techniques, it enables automotive professionals to deliver faster turnaround times while maintaining high standards. Moreover, the precision and accuracy of plastic welding make it an ideal solution for intricate car bodywork repairs, ensuring every detail is considered and preserved.

Benefits of Using Plastic Welding for Car Restoration

Plastic welding technology has become an indispensable tool in the automotive restoration process, offering a range of benefits that have transformed the way vehicle repairs are approached. One of its key advantages is the ability to seamlessly fuse various plastic components, which is particularly crucial in modern cars where plastics are extensively used for body panels and interior parts. This advanced technique ensures structural integrity and long-lasting durability, making restored vehicles nearly indistinguishable from their original state.

For auto repair near me, fleet repair services, or a comprehensive auto collision center, plastic welding provides an efficient solution. It allows technicians to repair or replace cracked, damaged, or missing plastic parts without the need for costly replacement of entire panels. This not only reduces expenses but also minimizes downtime for vehicle owners. The precision and versatility of plastic welding technology enable restorers to achieve flawless results, enhancing both the aesthetic appeal and safety features of vehicles across different makes and models.

The Role of Plastic Welding in Modern Auto Body Repair

In modern auto body repair, plastic welding technology has emerged as an indispensable tool, revolutionizing the way we restore and repair vehicles. The traditional methods of using metal brackets and rivets for structural repairs are being supplemented—and in many cases replaced—by advanced plastic welding techniques. This shift is driven by several key factors. Firstly, modern vehicles are increasingly made with high-quality, durable plastics that require specialized welding to maintain their integrity. Secondly, plastic welding offers greater precision and less material waste compared to conventional methods, contributing to more efficient auto body services.

Moreover, the use of plastic welding technology plays a significant role in luxury vehicle repair and classic car restoration projects. For high-end vehicles, maintaining the original manufacturer’s aesthetic is paramount. Plastic welding ensures that repairs are invisible to the naked eye, preserving the vehicle’s sleek design and luxurious appeal. Similarly, in classic car restoration, where every detail matters, plastic welding technology allows restorers to accurately replicate original parts while ensuring structural integrity—a crucial aspect for both safety and historical accuracy in these cherished vehicles.

Plastic welding technology has emerged as a game-changer in vehicle repairs, revolutionizing auto body restoration. Its benefits are clear: it offers precise, durable bonds that enhance both structural integrity and cosmetic appeal. As modern vehicles incorporate more plastic components, the role of plastic welding technology becomes increasingly vital for keeping up with repair demands while ensuring safety and quality.