UV curing systems revolutionize auto repair by offering a swift, efficient alternative to traditional drying methods, reducing cure times and improving bonding strength. These eco-friendly systems eliminate harmful VOCs and enable faster turnaround times, enhancing shop efficiency. Despite high initial costs, many shops adopt UV technology for improved job quality, increased customer satisfaction, and minimal environmental impact.

“Discover the transformative power of UV curing systems in modern auto repair with our comprehensive guide. Explore the fundamentals of this innovative technology, which has revolutionized the industry due to its speed and precision. Delve into the science behind UV curing, understanding how it hardens resins instantly. Learn about its numerous benefits, from reduced dry times to improved efficiency. We’ll also navigate potential challenges and provide best practices for successful implementation in auto repair shops, ensuring top-quality finishes.”

- Understanding UV Curing Systems: The Basics and Their Rise in Auto Repair

- How UV Curing Works: The Science Behind the Process

- Implementing UV Curing in Auto Repair: Benefits, Challenges, and Best Practices

Understanding UV Curing Systems: The Basics and Their Rise in Auto Repair

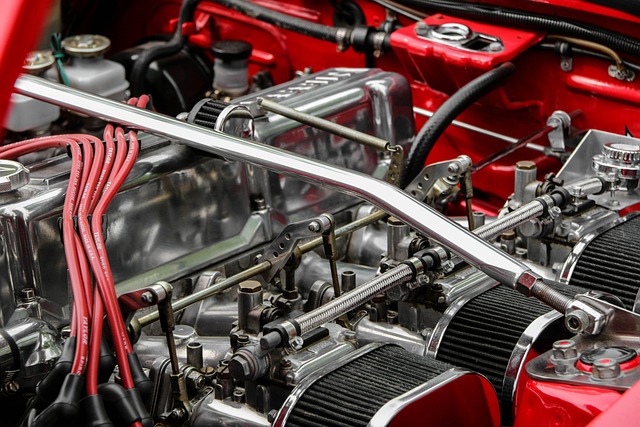

UV curing systems have revolutionized auto repair services, offering a faster and more efficient alternative to traditional drying methods. These systems utilize ultraviolet light to cure or harden various coatings, adhesives, and sealants used in automotive body shop operations. The rise of UV curing systems in auto collision centers can be attributed to several key advantages. Firstly, they significantly reduce the time required for drying, allowing technicians to complete repairs more promptly. Secondly, UV technology provides superior bonding strength and reduced curing times compared to conventional methods, ensuring high-quality finishes.

Moreover, UV curing systems are environmentally friendly, as they eliminate the need for potentially harmful volatile organic compounds (VOCs) often found in traditional paints and coatings. This makes them a preferred choice for modern auto repair shops looking to adopt more sustainable practices. With their ability to enhance productivity and quality while minimizing environmental impact, UV curing systems have become an indispensable tool in the automotive industry.

How UV Curing Works: The Science Behind the Process

UV curing systems revolutionize car bodywork services and auto maintenance practices. The process leverages ultraviolet light to rapidly cure or harden resins and coatings, offering a swift alternative to traditional drying methods. When UV light is absorbed by the resin, it initiates a chemical reaction known as polymerization. This transformative process creates strong, durable bonds between layers of material, ensuring seamless integration in car body restoration efforts.

The science behind UV curing involves precise control over wavelength and intensity. Specific UV wavelengths penetrate the surface of the resin, triggering a chain reaction that leads to cross-linking—a critical step in achieving maximum hardness and durability. This efficient, clean, and fast drying method not only reduces repair times but also minimizes environmental impact compared to traditional curing techniques used in auto maintenance.

Implementing UV Curing in Auto Repair: Benefits, Challenges, and Best Practices

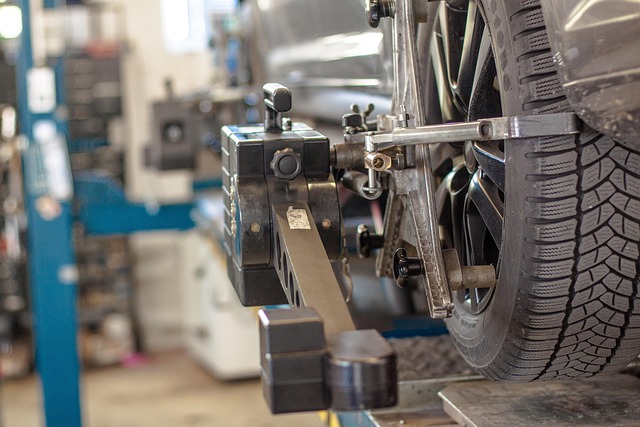

Implementing UV curing systems in auto repair offers a range of benefits that are transforming the industry. Firstly, it significantly reduces cure times compared to traditional drying methods, allowing for faster turnaround and increased shop efficiency. This is particularly beneficial for busy repair facilities where quick service is paramount. Additionally, UV curing provides superior bonding strength and consistency, ensuring long-lasting results in car scratch repair and paintless dent repair processes. The environmental advantages are also notable; UV systems use fewer solvents and release minimal odor, aligning with the industry’s push towards more eco-friendly practices.

However, there are challenges to consider when adopting UV curing technology. Initial investment costs can be high, requiring significant capital outlay for equipment and training. Furthermore, proper implementation demands adherence to best practices, including using the correct UV light intensity and exposure times to avoid overshooting or undercuring the repair. Despite these hurdles, many auto bodywork services are finding that the benefits of UV curing systems outweigh the challenges, leading to improved job quality, increased customer satisfaction, and enhanced workshop productivity.

UV curing systems have emerged as a game-changer in the auto repair industry, offering efficient and precise drying solutions. By understanding the science behind these systems and implementing best practices, technicians can optimize workflow, reduce cure times, and achieve superior results. The benefits of UV curing are clear, but challenges exist, from equipment investment to proper training. As auto repair continues to evolve, embracing innovative technologies like UV curing systems will be key to staying competitive and delivering high-quality repairs.