Infrared paint drying revolutionizes automotive and industrial painting by dramatically speeding up dry times while ensuring high-quality finishes. This technology directly heats paint, evaping solvents quickly and eliminating defects. Ideal for car repairs, it offers faster turnaround times, especially for hail damage, with consistent results. Best practices include using proper application tools, clean surfaces, and controlled heating for optimal infrared paint drying outcomes.

Infrared (IR) paint drying technology has emerged as a game-changer in the coatings industry, offering significant advantages over traditional drying methods. This innovative approach enhances productivity and ensures high-quality results by accelerating the curing process of paints and coatings. Understanding IR paint drying’s unique mechanisms and its benefits is crucial for professionals aiming to achieve superior finishing. From efficient project completion to enhanced product durability, this article explores how infrared paint drying contributes to excellence in every step.

- Understanding Infrared Paint Drying Technology

- Advantages for Achieving High-Quality Results

- Best Practices for Optimal Application and Curing

Understanding Infrared Paint Drying Technology

Infrared paint drying is a revolutionary technology that has transformed the automotive and industrial painting sectors. This innovative process utilizes infrared (IR) radiation to speed up the drying time of paints, significantly improving efficiency in car paint services and auto painting operations. Unlike traditional methods that rely on ambient or convective heat, IR drying offers a more direct and intense heating mechanism. By emitting infrared waves, the technology heats the paint directly, causing rapid evaporation of solvents and accelerating the chemical reactions responsible for hardening the finish.

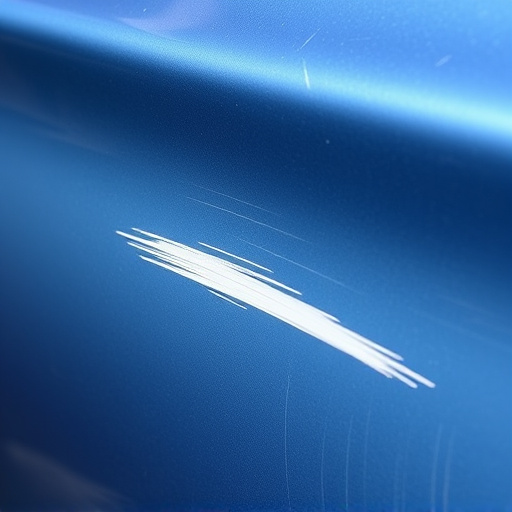

This advanced technique is particularly beneficial for car paint repair and restoration projects, where achieving high-quality results quickly is paramount. With infrared paint drying, auto painting professionals can reduce dry times from minutes to seconds, allowing them to complete more jobs in less time without compromising on quality. The technology’s ability to provide a consistent and controlled heating process ensures even drying, minimizing the risk of blistering, warping, or other defects commonly associated with conventional painting methods.

Advantages for Achieving High-Quality Results

Infrared paint drying offers significant advantages when it comes to achieving high-quality results in collision repair shops and car body repair facilities. This innovative technology accelerates the curing process, ensuring faster turnaround times without compromising on the final finish. By using infrared heat, the paint is cured more quickly than traditional methods, minimizing the risk of fingerprints, bubbles, or other imperfections that can occur during manual drying.

This efficient process is particularly beneficial for hail damage repair, where speed and precision are crucial to restoring vehicles to their pre-damage condition. Infrared paint drying ensures even heating across the car body, eliminating hot spots that could lead to uneven curing. As a result, repairs are not only quicker but also more consistent, ultimately enhancing the overall quality of the finished product in both collision repair shop and car body repair settings.

Best Practices for Optimal Application and Curing

For optimal results with infrared paint drying, best practices involve careful application and controlled curing. When applying the paint, ensure even distribution by using a professional sprayer or roller, maintaining proper distance and pressure to avoid overspray or inconsistent coating. The surface should be clean, dry, and free from contaminants to prevent impurities that could hinder drying. For car damage repair or autobody repairs, this meticulous approach is crucial in achieving high-quality finishes.

Curing involves allowing the paint to set at the recommended temperature and duration. Infrared technology accelerates the process by evenly heating the surface, reducing cure times compared to traditional methods. Maintaining a consistent environment during curing, including temperature and humidity control, ensures uniform drying. This meticulous attention to detail, combined with infrared paint drying, results in superior finishes, making it a preferred method for both automotive repair professionals and those seeking top-tier autobody repairs near me.

Infrared paint drying technology offers a significant advantage in achieving high-quality, durable finishes. By understanding its unique properties and best practices, professionals can optimize application and curing processes, ensuring superior results in various industries. Incorporating infrared paint drying into your workflow can revolutionize your painting projects, leading to faster drying times, improved surface quality, and consistent outcomes.