3D vehicle scanning technology enhances car repair services with precise, detailed digital models of vehicles, surpassing traditional 2D imaging. This method is invaluable for complex repairs on luxury cars, ensuring accurate damage identification and measurement, effective communication, transparency, and comprehensive documentation. It streamlines the repair process, facilitates remote consultations, accelerates claim settlements, and improves tracking, making it a game-changer in auto body shops, especially for classic car restoration.

In today’s digital era, 3D vehicle scanning is transforming auto repair with unprecedented precision and efficiency. This advanced technology captures detailed, three-dimensional models of vehicles, providing mechanics with a comprehensive view unseen through traditional methods. By understanding 3D scanning technology and its benefits, shops can enhance accuracy, streamline repairs, and reduce costs. This guide delves into the process, offering a step-by-step approach to successfully incorporating this game-changing tool into your auto repair practices.

- Understanding 3D Vehicle Scanning Technology

- Benefits of Incorporating 3D Scanning in Auto Repair

- Step-by-Step Guide to Applying 3D Vehicle Scanning

Understanding 3D Vehicle Scanning Technology

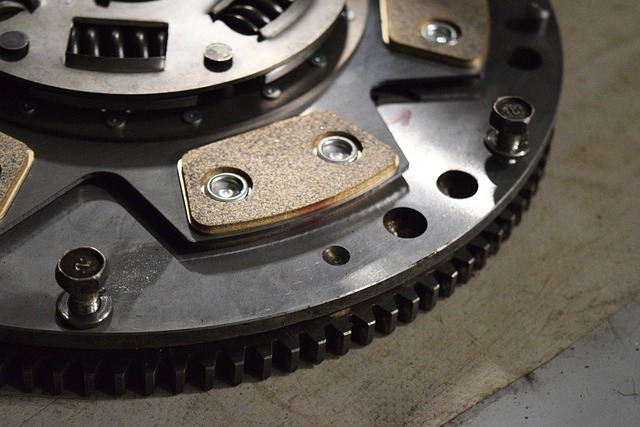

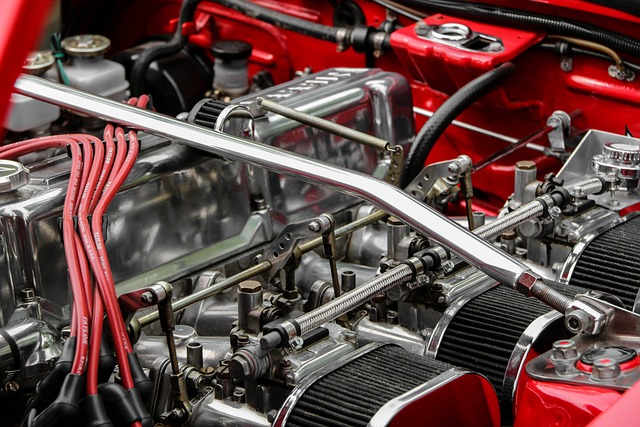

3D vehicle scanning technology has revolutionized car repair services, offering an advanced and precise method to assess and document vehicle damage. This innovative process involves capturing detailed 3D images or point clouds of a vehicle’s exterior and interior, providing a comprehensive digital model. By employing specialized scanners, every curve, contour, and detail of the car’s surface is meticulously recorded, creating a virtual representation that surpasses traditional 2D imaging.

This technology is particularly beneficial for complex repairs, such as those on luxury vehicles like Mercedes Benz. With 3D scanning, mechanics can accurately identify and measure scratch repair areas, ensuring precise restoration. The digital model allows for detailed analysis, facilitating effective communication between repair teams and customers. This level of precision not only guarantees superior car repair services but also ensures that every aspect of the vehicle’s condition is documented, promoting transparency and trust in the repair process.

Benefits of Incorporating 3D Scanning in Auto Repair

Incorporating 3D scanning technology into auto repair processes offers a multitude of benefits for both workshops and customers. One of the key advantages is its ability to revolutionize damage assessment, especially in complex cases like hail damage repair or vehicle collision repair. With precise, detailed scans, auto body shops can now identify and measure even the subtlest dents, cracks, or deformities with unparalleled accuracy. This level of detail allows for more accurate estimates and repairs, ensuring that every part of the vehicle is addressed effectively.

3D scanning also streamlines the entire repair process, from initial assessment to final reconditioning. It provides a digital record of the vehicle’s original state, making it easier to track progress and ensure that any changes are authorized. Moreover, by enabling remote consultations and comparisons, 3D scanning can enhance communication between auto body shops, insurance providers, and customers, leading to faster claim settlements and more transparent repairs.

Step-by-Step Guide to Applying 3D Vehicle Scanning

Applying 3D vehicle scanning is a game-changer for auto repair professionals, especially when tackling complex jobs like classic car restoration. This technology allows for an in-depth digital analysis of a vehicle’s structure, enabling precise measurements and detailed imaging. Here’s a step-by-step guide to mastering this process:

1. Preparation: Begin by ensuring the vehicle is clean and free from any debris. Park it on a stable surface for optimal scanning accuracy. For classic cars or unique vehicles, consider removing any parts that might interfere with the scan, such as wheels or custom accessories.

2. Scanning Process: Utilize advanced 3D scanning equipment, often a handheld device or a mobile unit. Position the scanner around the vehicle, capturing multiple angles and views. Ensure comprehensive coverage, including the exterior, underbody, and interior where applicable. The technology will create a digital point cloud, transforming the vehicle into a detailed 3D model.

3. Data Analysis: Once scanning is complete, software processes the data, creating precise measurements and high-resolution images. This step allows auto repair technicians to identify potential issues or damage, especially in hard-to-reach areas. For instance, collision repair services can benefit from this detailed analysis when repairing crumpled panels or realigning frames.

4. Restoration/Repair: With the 3D scan data, mechanics can plan and execute repairs with enhanced accuracy. In classic car restoration projects, it ensures that every detail is preserved and restored to its original state. This advanced technique reduces the risk of errors, minimizing costly mistakes often associated with traditional measurement methods.

3D vehicle scanning is transforming auto repair by offering precise, detailed data for more accurate and efficient diagnostics and repairs. By incorporating this innovative technology, shops can enhance their service offerings, reduce time and material costs, and ultimately provide better value to customers. With its many benefits and straightforward application process, 3D scanning is a game-changer in the auto industry that repair shops would be wise to explore further.