Computerized frame measurement revolutionizes vehicle damage assessment, offering fast, accurate digital blueprint analysis of car frames. In auto body shops, this technology detects subtle dents and misalignments, enhancing repair precision, efficiency, and saving resources by minimizing work on undamaged parts. Advanced systems identify hidden imperfections, ensuring comprehensive collision damage repair for improved safety and structural integrity.

Computerized frame measurement has transformed the way structural damage is assessed, offering a powerful tool for detecting hidden issues that may go unnoticed through visual inspection. This advanced technology utilizes sophisticated scanning techniques to uncover subtle weaknesses and defects within building frames. By analyzing data beyond what the human eye can perceive, it ensures structures are safe and sound, revolutionizing preservation efforts in today’s digital era.

- Computerized Frame Scanning: A Powerful Tool

- Detecting Damage Beyond the Eye

- Preserving Structures: The Digital Approach

Computerized Frame Scanning: A Powerful Tool

Computerized frame scanning has emerged as a powerful tool in the automotive industry, revolutionizing how hidden damage is detected and assessed. Unlike traditional manual measurements, which can be time-consuming and prone to human error, computerized frame measurement systems utilize advanced technology to quickly and accurately analyze vehicle frames. These systems employ sensors and high-resolution cameras that meticulously capture every contour and angle of a car’s structure, providing a detailed digital blueprint.

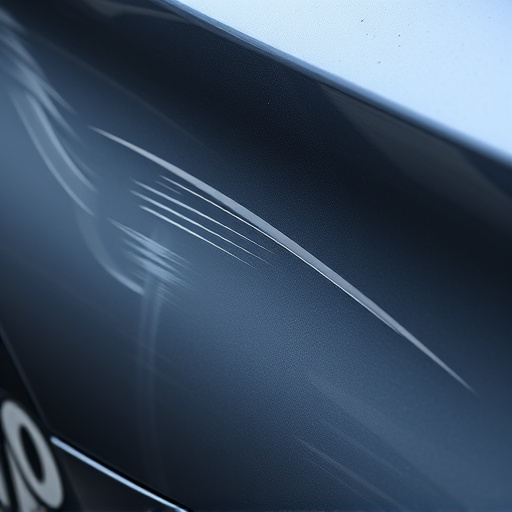

This innovative approach is particularly valuable in auto body shops and collision centers where identifying subtle dents, bends, or misalignments is crucial for effective dent repair. By feeding this data into specialized software, technicians can run complex algorithms that compare the current frame condition against pre-accident benchmarks, revealing hidden damage that may have gone unnoticed during a visual inspection. This not only ensures more precise repairs but also saves time and resources by minimizing unnecessary work on undamaged components.

Detecting Damage Beyond the Eye

Damages to vehicles aren’t always immediately apparent, especially when it comes to hidden or subtle imperfections. This is where computerized frame measurement techniques prove invaluable in the car repair shop and collision damage repair process. Beyond what the naked eye can detect, these advanced systems can identify discrepancies in a vehicle’s frame, revealing potential issues that could compromise its safety and structural integrity.

Computerized frame measurement tools utilize sophisticated sensors and software to analyze the precise dimensions of a car’s frame, including measurements taken before and after any accidents or repairs. By comparing these data points, professionals in car restoration can pinpoint hidden damage such as cracks, deformations, or misalignments, ensuring that every part of the vehicle is thoroughly inspected and any necessary collision damage repair is accurately assessed.

Preserving Structures: The Digital Approach

In today’s digital era, computerized frame measurement has revolutionized vehicle collision repair and bumper repair processes. Traditional methods often relied on manual inspections, which could be subjective and prone to human error. However, with advanced technology, professionals now employ precise, non-destructive testing techniques to detect even the subtlest signs of damage hidden beneath a vehicle’s surface. This digital approach ensures that every aspect of the frame is meticulously evaluated, preserving the structural integrity of the vehicle.

By automating the measurement process, experts can quickly identify issues like bent panels, misaligned components, or hidden cracks that might otherwise go unnoticed. This not only speeds up the repair process but also enhances the overall quality of vehicle restoration. Computerized systems provide detailed reports with exact measurements and visual aids, making it easier to track progress and communicate potential challenges to clients, ultimately leading to a safer and more reliable transportation experience.

Computerized frame measurement techniques have revolutionized structural inspection, enabling professionals to detect hidden damage with unprecedented precision. By utilizing advanced scanning technologies, these methods go beyond visual inspections, providing a detailed digital tapestry of a structure’s integrity. This innovative approach ensures the preservation and longevity of buildings by identifying subtle flaws that might otherwise go unnoticed, thereby fostering safer and more robust construction practices.