Tesla's Factory Specifications guide certified technicians through every production stage, ensuring quality control, precise repairs, and maintaining the brand's reputation. Certification requires rigorous training in Tesla's unique systems, with focus on electric powertrains, software, and battery service. Quality assurance teams and advanced equipment streamline processes, upholding Tesla's high manufacturing standards.

“Uncover the secrets behind Tesla’s exceptional quality control with our comprehensive guide. This article delves into the critical role of certified technicians in maintaining the brand’s high standards. From understanding the intricate Tesla factory specifications to rigorous training requirements, we explore how these professionals ensure every vehicle meets exacting criteria. Discover the on-site quality assurance processes that make Tesla vehicles synonymous with innovation and precision engineering.”

- Understanding Tesla Factory Specifications Overview

- Certified Technician Training Requirements

- Maintaining High Standards: On-Site Quality Assurance

Understanding Tesla Factory Specifications Overview

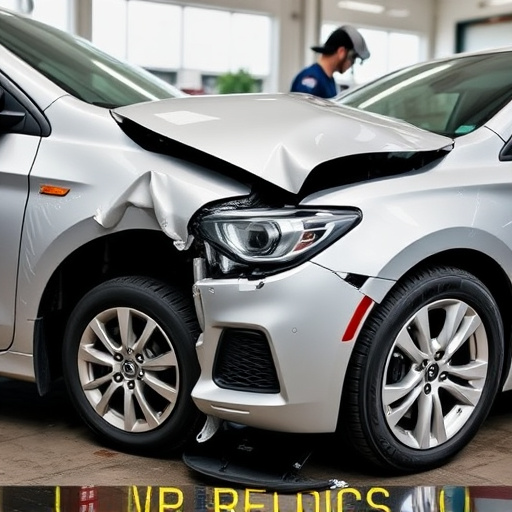

Tesla’s Factory Specifications serve as a comprehensive guide for certified technicians, outlining the exact standards and procedures to be followed during every stage of vehicle production. This detailed document ensures that each Tesla rolled off the assembly line meets the company’s stringent quality control measures. Understanding this guide is crucial for technicians, as it enables them to perform precise, consistent repairs and modifications, whether it’s for regular maintenance or addressing rare car damage repair scenarios.

By adhering to these specifications, certified professionals can guarantee that any repairs, including car scratch repair or more complex vehicle repair cases, are carried out with the utmost accuracy. This not only maintains Tesla’s reputation for excellence but also ensures customer satisfaction and safety. The factory specifications act as a constant reference point, fostering a culture of precision and quality within the technician community, thereby reducing the likelihood of costly car damage during what might otherwise be intricate repair processes.

Certified Technician Training Requirements

To become a Certified Technician for Tesla’s factory-spec guidelines, candidates must undergo rigorous training that combines theoretical knowledge with hands-on experience. This involves mastering Tesla’s unique vehicle architecture, advanced electric powertrains, and cutting-edge software systems. The training program ensures technicians are equipped to handle the intricate repairs and maintenance of these modern, high-tech automobiles.

The process includes specialized courses tailored to Tesla’s factory specifications, covering topics such as battery pack servicing, autonomous driving components, and over-the-air updates. Technicians also learn about diagnostic tools specific to electric vehicles (EVs), enabling them to accurately identify and resolve issues in these complex car repair shops. This rigorous training is essential for maintaining the superior quality and performance standards set by Tesla, especially when compared to traditional automotive restoration or classic car restoration practices.

Maintaining High Standards: On-Site Quality Assurance

Maintaining high standards is at the heart of Tesla’s manufacturing process, and this extends to their factory specifications. Certified technicians play a pivotal role in ensuring that every vehicle leaving the Tesla factory meets these stringent criteria. On-site quality assurance teams conduct meticulous inspections, scrutinizing every detail from the precision of panel fits to the integrity of components like auto glass replacement and car dent repair. This rigorous process guarantees that only flawless vehicles roll off the production line, embodying Tesla’s commitment to excellence.

The factories themselves are designed with a focus on efficiency and quality control. Streamlined workflows and state-of-the-art equipment enable technicians to work swiftly yet meticulously, minimizing errors and maximizing consistency. By adhering strictly to Tesla factory specifications, these experts contribute to the overall quality and reliability of each vehicle, ensuring that every car dent repair, auto glass replacement, or other maintenance task is executed flawlessly.

Tesla’s commitment to innovation and quality is reflected in its meticulous factory specifications. By certifying technicians through rigorous training and on-site quality assurance, Tesla ensures that every vehicle meets its high standards. Understanding these specifications is key for professionals aiming to excel in the electric vehicle industry, ensuring that each Tesla rolls off the line with precision and excellence.