Adhesive bonding techniques are essential for high-end car repairs, using advanced adhesives to match factory standards and ensure structural integrity & cosmetic appeal. Choosing the right adhesive considers material compatibility, environmental conditions, and flexibility/rigidity, balancing epoxy's strength with polyurethane's adaptability. A meticulous approach includes cleaning, measuring, cutting, applying adhesive, positioning, and curing for successful reinforcement panel repairs.

“Adhesive bonding techniques offer a powerful solution for reinforcement panel repairs, ensuring structural integrity and longevity. This comprehensive guide explores the art of adhering panels with precision and strength. From understanding the fundamentals of adhesive bonding to selecting the ideal adhesive for your application, we provide valuable insights.

Learn how to apply adhesives effectively and cure them properly for optimal results. Discover the steps to ensure long-lasting repairs, making it an indispensable resource for professionals in the industry.”

- Understanding Adhesive Bonding Basics for Panel Repairs

- Choosing the Right Adhesive for Strength and Durability

- Step-by-Step Guide to Effective Adhesive Application and Curing

Understanding Adhesive Bonding Basics for Panel Repairs

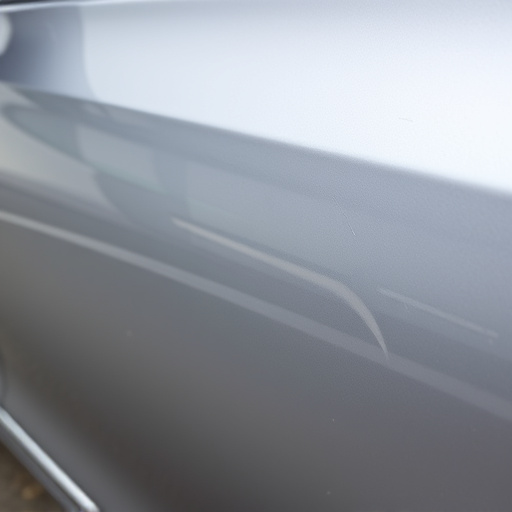

Adhesive bonding is a crucial technique in panel repairs for vehicles like Mercedes-Benz, as it offers a strong and lasting solution. This process involves applying an adhesive to join two surfaces together, creating a durable bond. In collision repair services, understanding the basics of adhesive bonding techniques is essential for ensuring structural integrity and cosmetic satisfaction.

At reputable auto repair shops, professionals use advanced adhesives tailored for specific materials used in car manufacturing. By carefully selecting the right adhesive and preparing the surfaces properly, technicians can achieve bonds comparable to or even exceeding the strength of the original factory bond. This method is particularly valuable for reinforcing panel repairs, enhancing both safety and aesthetics.

Choosing the Right Adhesive for Strength and Durability

When selecting an adhesive for reinforcement panel repairs in a car body shop or collision repair center, it’s paramount to consider both strength and durability. Different adhesives are formulated to handle specific materials and environmental conditions, so understanding your application is key. For instance, epoxy adhesives offer superior strength and resistance to chemicals, making them ideal for structural repairs in automotive applications. Polyurethane adhesives, on the other hand, provide excellent flexibility and bond well with various surfaces, which can be beneficial when repairing complex panel shapes.

Choosing the right adhesive also depends on factors like temperature, moisture levels, and exposure to UV light. In car paint services, where aesthetics are crucial, a high-performance adhesive ensures a strong bond that maintains the original finish’s integrity. By carefully matching the adhesive to the repair requirements, collision repair centers can achieve long-lasting, structurally sound repairs, ensuring vehicles return to the road safely and looking their best.

Step-by-Step Guide to Effective Adhesive Application and Curing

To achieve successful adhesive bonding for reinforcement panel repairs in collision repair or frame straightening, a meticulous approach is essential. First, ensure your work surface is clean and free from contaminants. This includes dust, grease, and any loose debris that could impede adhesion. Next, carefully measure and cut the reinforcement panel to fit the specific vehicle body repair area requiring reinforcement.

Once prepared, apply an even coat of adhesive suitable for the task, following the manufacturer’s guidelines. This is crucial for effective bonding. After applying the adhesive, precisely position the reinforcement panel, pressing it firmly into place. Maintain pressure until the adhesive starts to set, usually within a few minutes. Proper curing requires time and environmental conditions as specified by the adhesive manufacturer, often involving temperature and humidity control for optimal results in vehicle body repair projects.

Adhesive bonding techniques offer a powerful solution for reinforcement panel repairs, ensuring strength, durability, and longevity. By understanding the basics of adhesive bonding, selecting the right adhesive, and following effective application and curing practices, you can achieve superior repair results that rival the original structure. Incorporating these adhesive bonding techniques into your repair process will not only restore functionality but also enhance the overall structural integrity of panels in various industries.