PDR for aluminum panels is a specialized automotive repair technique that preserves original finishes and structural integrity on cars like Mercedes Benz. It requires skilled technicians using specific tools to gently restore damaged panels. Investing in correct equipment enhances repair quality, streamlines processes, and satisfies customers. Mastering advanced techniques involves understanding aluminum's properties, precise pressure points, and final polishing for seamless integration of repaired areas. Expertise can be enhanced through online resources, making you a sought-after choice for PDR services, including scratch repairs and auto glass replacement.

“Unleash the potential of repair and restoration with the next generation of PDR (Paintless Dent Repair) techniques tailored for aluminum panels. This comprehensive guide navigates your journey from understanding the fundamentals of PDR for aluminum to mastering advanced techniques. Learn how the right tools and equipment can make all the difference in achieving perfect, factory-like finishes. By exploring these steps, you’ll revolutionize the way you handle dents and scratches on aluminum surfaces.”

- Understanding the Basics of PDR for Aluminum Panels

- Choosing the Right Tools and Equipment for PDR on Aluminum

- Advanced Techniques to Master in PDR for Aluminum Panels

Understanding the Basics of PDR for Aluminum Panels

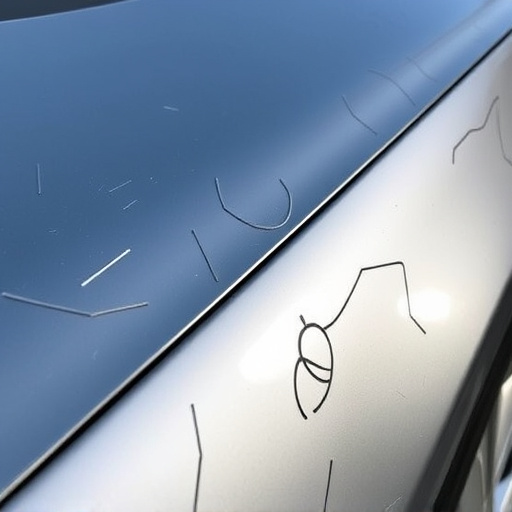

PDR for aluminum panels involves a specialized process to repair and restore dented or damaged automotive surfaces, specifically on aluminum cars and trucks. It’s a game-changer in the auto body services industry, offering an efficient and cost-effective alternative to traditional paintless damage repair methods. This technique has gained popularity due to its ability to preserve the original factory finish of vehicles, making it particularly appealing for high-end brands like Mercedes Benz repair.

By employing PDR techniques, skilled technicians can swiftly address various types of panel damage, from minor dents and dings to more significant creases and bends. The process leverages specialized tools and expertise to gently work out the metal without compromising its structural integrity or the overall appearance. This not only ensures superior results in automotive repair but also extends the lifespan of vehicles, making it a preferred choice for those seeking top-notch mercedes benz repair or any high-quality auto body services.

Choosing the Right Tools and Equipment for PDR on Aluminum

When it comes to PDR for aluminum panels, selecting the right tools and equipment is paramount to achieving professional results. For auto repair shops specializing in car bodywork, a comprehensive set should include specialized dent pullers designed specifically for aluminum—these tools offer the precision required to navigate the unique properties of this material without causing damage. Additionally, invest in high-quality paintless dent repair kits that feature advanced technology for effective hail damage repair, ensuring minimal scratch marks and precise restoration.

The right equipment not only facilitates efficient PDR but also enhances the overall quality of the repair. Consider durable and ergonomic tools that are easy to maneuver, even for intricate dent removal on complex car bodywork designs. Remember, a well-equipped shop is better prepared to handle various PDR challenges, ensuring customer satisfaction and fostering trust in your services among those seeking hail damage repair solutions.

Advanced Techniques to Master in PDR for Aluminum Panels

As you delve deeper into PDR for aluminum panels, advanced techniques will help you achieve flawless results. One key area to master is understanding the unique properties of aluminum. This metal has distinct characteristics compared to more common materials like steel or plastic, requiring precise pressure points and specialized tools. Advanced training in this aspect ensures your repairs are not just visible but also structural sound.

Additionally, learning advanced PDR techniques involves mastering the art of compounding and polishing. These final stages require a steady hand and an eye for detail to seamlessly blend repaired areas with the surrounding panel. With these skills honed, you’ll be equipped to handle complex damage, from deep scratches to dents, transforming them into virtually invisible repairs. Remember, seeking out resources like online tutorials or workshops focused on PDR for aluminum panels can significantly enhance your expertise, making you a go-to option for auto repair near me, even for challenging scratch repair and auto glass replacement cases.

As you’ve explored the fundamentals, tools, and advanced techniques of PDR for aluminum panels, remember that mastering this skill requires practice and dedication. Continuously refining your techniques and staying updated with industry best practices will ensure optimal results in every repair job. Embrace the art of PDR, and watch as your skills transform damaged aluminum panels into like-new surfaces.