Mercedes spot weld bonding is an innovative technique reinforcing structural stability, mitigating overheating and panel warpage during auto painting and collision repair. This method uses specialized adhesives for robust metal panel bonding, minimizing heat input and preserving vehicle shape. Ideal for intricate body work, it enhances customer satisfaction and vehicle quality by maintaining dimensional stability under extreme conditions. Implementing this requires precise alignment, clean environments, high-quality adhesives, quality control, and regular maintenance checks.

Mercedes-Benz has pioneered an innovative spot weld bonding technique that revolutionizes panel joining. By minimizing heat input, this method avoids the common issues of overheating and warpage, ensuring structural integrity and aesthetic precision in their vehicles. This article delves into the understanding, benefits, and implementation best practices of Mercedes spot weld bonding, highlighting its significance in modern automotive manufacturing.

- Understanding Mercedes Spot Weld Bonding Technique

- Benefits: Avoiding Overheating and Warpage

- Implementation: Best Practices for Success

Understanding Mercedes Spot Weld Bonding Technique

Mercedes uses a specialized technique known as spot weld bonding to ensure structural integrity and prevent common issues like overheating and panel warpage. This method goes beyond traditional spot welding by utilizing advanced adhesives that create a powerful bond between metal panels. By precisely applying these adhesives, Mercedes engineers can achieve robust connections while minimizing heat input, which is a key factor in preventing damage during the auto painting and vehicle collision repair processes.

The spot weld bonding technique involves strategically placing adhesive dots at specific points along the joint line. These dots are then activated using specialized equipment to create a strong, lasting bond. This method allows for precise control over the amount of adhesive used, ensuring that no excess material is applied. This not only contributes to the overall aesthetics of the vehicle but also helps in maintaining the original shape of the panels, even after exposure to high temperatures during automotive repair processes like auto painting and vehicle collision repair.

Benefits: Avoiding Overheating and Warpage

Mercedes spot weld bonding offers significant advantages when it comes to preserving the integrity of a vehicle’s structure. By strategically applying this technique, automotive body shops can effectively prevent overheating during the repair process. Overheating is a common issue in car body restoration, particularly with metal panels, as the heat from welding can cause warping and distortion. This can be detrimental to the overall appearance and safety of the vehicle, leading to expensive rework or even structural failures.

The method ensures precise bonding between components, eliminating the risk of unwanted temperature rise. This is especially beneficial for intricate car body restoration projects where panel alignment and finish are paramount. Spot weld bonding provides a robust and durable solution, guaranteeing that the repaired area maintains its dimensional stability and remains free from warpage, even under extreme conditions. As such, it has become an indispensable practice in modern vehicle body shops, ensuring customer satisfaction and preserving the quality of restored vehicles.

Implementation: Best Practices for Success

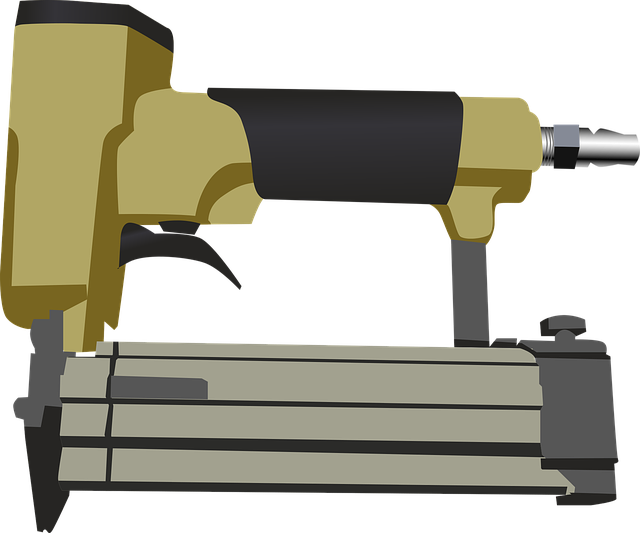

Implementing Mercedes spot weld bonding requires a meticulous approach for optimal results. In a vehicle body shop, ensuring precise alignment and secure bonding is key to preventing panel warpage. The process involves careful selection of adhesives suitable for automotive applications, adhering to manufacturer guidelines, and utilizing specialized equipment like robotic welding systems or manual spot weld guns. Proper training for technicians is essential, as it ensures consistent pressure and distance during the bonding process, minimizing the risk of overheating sensitive materials.

For fleet repair services looking to incorporate this technique, establishing a standardized protocol is beneficial. This includes maintaining a clean, dust-free environment, using high-quality adhesives designed for extreme conditions, and implementing quality control measures. Regular maintenance checks post-bonding further ensure the integrity of repairs in car paint services, guaranteeing longevity and aesthetics for Mercedes vehicles.

Mercedes’ innovative spot weld bonding technique significantly enhances structural integrity by preventing overheating and panel warpage, ensuring precision and durability in vehicle construction. By adopting best practices, manufacturers can achieve seamless fusion, ultimately contributing to high-quality automotive production. This method is a game-changer for the industry, highlighting the importance of advanced joining technologies like Mercedes spot weld bonding.