Composite material replacement revolutionizes vehicle dent repair and body shop practices with efficient, cost-effective, and durable solutions compared to traditional metal. These materials maintain structural integrity and aesthetic appeal through precise molding, offer enhanced durability, corrosion resistance, and impact absorption, ensuring long-lasting repairs that streamline processes, enable intricate design work, mitigate corrosion, and improve vehicle performance in automotive settings. A meticulous approach, including thorough inspection, precise removal techniques, proper preparation, and adherence to best practices, enhances repair quality, structural integrity, and customer satisfaction in car paint services, bodywork, or auto collision centers.

Composite material replacement is a game-changer in repair work, offering sustainable and efficient solutions. This article delves into the significance of understanding composite materials and their unique properties in various repairs. We explore the numerous advantages of replacing composite components, from cost-effectiveness to enhanced structural integrity. Additionally, best practices are outlined to ensure successful composite material replacement, providing a comprehensive guide for professionals navigating this innovative approach.

- Understanding Composite Materials in Repairs

- Advantages of Replacing Composite Components

- Best Practices for Effective Composite Material Replacement

Understanding Composite Materials in Repairs

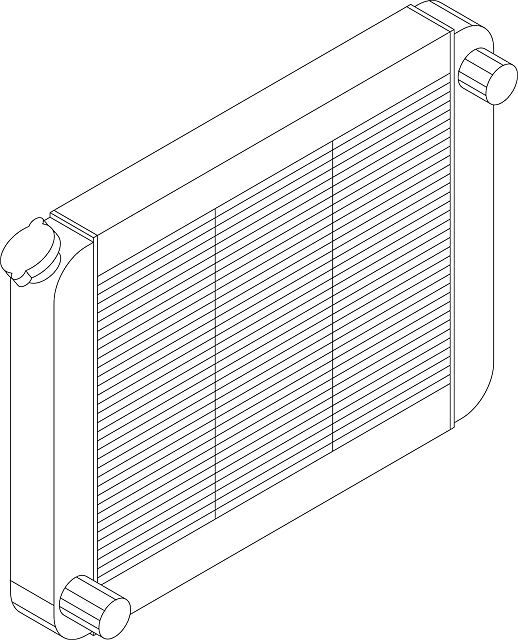

Composite materials have revolutionized the automotive repair industry, particularly in vehicle dent repair and car body shop settings. These innovative materials are designed to mimic the strength and aesthetics of original components, offering a lightweight alternative to traditional metal. In the realm of automotive repair, understanding composite material replacement is paramount for several reasons.

When a car undergoes a dent or damage, composite material replacements provide an efficient and cost-effective solution. Unlike metal, composites can be molded and shaped with precision, allowing for seamless integration into the existing structure. This not only ensures structural integrity but also retains the vehicle’s original appearance. Moreover, composite materials offer enhanced durability, resistance to corrosion, and better impact absorption, making them a superior choice for long-lasting repairs in automotive settings.

Advantages of Replacing Composite Components

Composite material replacement offers significant advantages when it comes to auto body repairs. Unlike traditional metal panels, composite materials are lightweight yet incredibly strong and durable. This makes them an ideal choice for modern car bodywork, as they can withstand impact better while reducing overall vehicle weight, leading to improved fuel efficiency.

In a car repair shop, replacing composite components is often more efficient than repairing or replacing metal parts. Composites can be molded into complex shapes, allowing for intricate design work and seamless panel fit during the auto body repairs process. Moreover, they are less prone to corrosion, ensuring that the vehicle’s structural integrity remains intact over time, even in harsh environmental conditions.

Best Practices for Effective Composite Material Replacement

When undertaking composite material replacement in repairs, best practices dictate a meticulous approach for optimal results. It begins with thorough inspection to identify and isolate damaged or deteriorated composite components accurately. This involves using specialized tools and techniques to assess the extent of the damage, ensuring no underlying issues are overlooked. Once identified, the removal process demands precision, employing safe methods to prevent further contamination or damage to surrounding materials.

After removal, proper preparation is key. This includes cleaning the affected area to remove any debris or remnants, followed by priming and coating to create a solid foundation for new composite material application. Utilizing high-quality products and adhering to manufacturer guidelines ensures long-lasting durability. Incorporating these practices in car paint services, car bodywork services, or at an auto collision center enhances repair quality, reinforces structural integrity, and guarantees customer satisfaction.

Composite material replacement is a game-changer in repair practices, offering numerous advantages over traditional methods. By understanding the unique properties of composite materials and implementing best practices, professionals can ensure long-lasting, structurally sound repairs. This innovative approach not only enhances the durability of structures but also promotes sustainability by reducing waste associated with obsolete composite components. Embracing composite material replacement is a crucial step towards modern, efficient, and environmentally conscious repair strategies.