An ultrasonic thickness gauge is a critical tool in auto repair, ensuring structural integrity and high-quality craftsmanship by detecting hidden damage through sound wave measurements. This non-invasive technique allows mechanics to accurately assess body panels and parts, facilitating efficient maintenance and preventing potential issues. The gauge revolutionizes repairs by providing precise data for informed decisions, enhancing overall vehicle quality and customer satisfaction.

In the precision world of auto repair, detecting hidden damage and ensuring structural integrity is paramount. This is where an ultrasonic thickness gauge (UTG) becomes an indispensable tool. This non-invasive device uses sound waves to measure metal panels’ thickness, revealing potential issues that might go unnoticed otherwise. By providing accurate and precise measurements, UTGs play a pivotal role in efficient auto repair, allowing technicians to make informed decisions, streamline repairs, and ultimately, enhance vehicle safety.

- Uncovering Hidden Damage with Ultrasonic Thickness Gauge

- Precision Measurement: Why It Matters in Auto Repair

- Streamlining Repairs: Benefits of Using Ultrasonic Thickness Gauge

Uncovering Hidden Damage with Ultrasonic Thickness Gauge

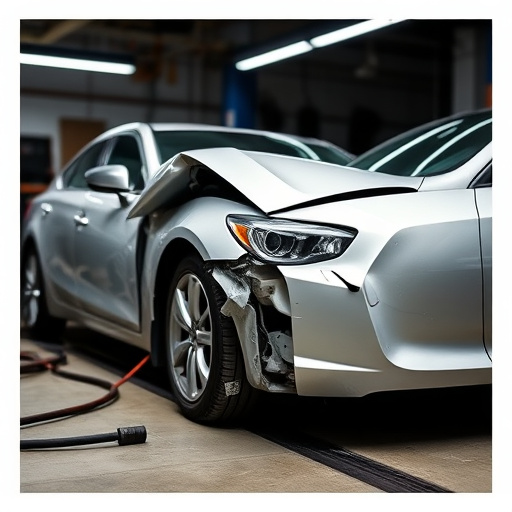

In the realm of auto repair, accurate measurements are key to ensuring structural integrity and quality craftsmanship. This is where an ultrasonic thickness gauge steps in as a valuable tool. By sending high-frequency sound waves into a vehicle’s panel or component, these gauges can reveal hidden damage that might otherwise go unnoticed during visual inspections. Even minor cracks, corrosion, or uneven repairs can be detected by measuring the echo time of the sound waves, providing auto technicians with crucial insights for precise vehicle restoration and seamless bumper repair.

Moreover, the ultrasonic thickness gauge plays a pivotal role in auto maintenance by enabling mechanics to assess the condition of various parts, from body panels to fenders. This non-invasive technique allows for more effective and efficient repairs, enhancing the overall quality of auto maintenance services.

Precision Measurement: Why It Matters in Auto Repair

In auto repair, precision measurement is paramount to ensuring the highest quality work and customer satisfaction. The ultrasonic thickness gauge plays a pivotal role in achieving this accuracy, especially in complex tasks like automotive collision repair and hail damage repair. This advanced tool allows technicians to measure the thickness of materials with remarkable exactness, which is crucial for safe and effective auto body services. By providing detailed measurements, it helps identify subtle changes or discrepancies that might be invisible to the naked eye, thereby preventing potential issues down the line.

The ability to precisely gauge material thickness is especially critical in repairing cars damaged by hailstorms or accidents. In these scenarios, understanding the remaining integrity of the vehicle’s components is essential for structural safety and long-term reliability. The ultrasonic thickness gauge enables mechanics to make informed decisions about repairs, replacement parts, and restoration techniques, ultimately guaranteeing that the vehicle meets stringent quality standards and returns to its pre-incident condition.

Streamlining Repairs: Benefits of Using Ultrasonic Thickness Gauge

Using an ultrasonic thickness gauge in auto repair offers numerous benefits that streamline processes and enhance efficiency in body shop services. This advanced tool enables technicians to accurately measure metal thickness, which is crucial for assessing damage, especially in car restoration projects. By quickly determining panel integrity, mechanics can make informed decisions about repairs, ensuring they are tailored to the specific needs of each vehicle.

Furthermore, an ultrasonic thickness gauge facilitates precise cutting and shaping of panels, reducing waste and the need for excessive material removal. This precision is vital for achieving a seamless finish during auto maintenance, resulting in higher-quality repairs that contribute to the overall aesthetics and structural integrity of the vehicle.

The adoption of ultrasonic thickness gauges in auto repair shops is a game-changer. By providing precise measurements, these tools help uncover hidden damage, streamline repairs, and enhance overall efficiency. In today’s digital era, where precision matters, an ultrasonic thickness gauge is no longer an option but an essential tool for any professional mechanic, ensuring top-quality and reliable car care.