Plasma cutting technology revolutionizes collision repair by offering faster, more precise results than traditional methods, preserving structural integrity and reducing heat impact. Before cutting, thorough preparation and safety planning are crucial, including specialized tools, trained personnel, and robust protocols for handling plasma cutters. After repair, meticulous inspection ensures accuracy, aligning cut lines with original design and manufacturer specifications for a seamless fit and finish on standard and luxury vehicles.

“In the realm of collision repair, plasma cutting has emerged as a game-changer, offering precision and efficiency. This article guides you through the intricacies of a plasma cutting collision repair job. From understanding the technology behind it, to preparing for the cut, and ensuring quality post-processing—we’ll cover it all. Discover how this innovative method revolutionizes auto body repairs, providing both precision and speed. Get ready to navigate the process with confidence.”

- Understanding Plasma Cutting Technology for Collision Repair

- Pre-Cutting Preparation and Safety Measures

- Post-Cutting Process and Quality Assurance Checks

Understanding Plasma Cutting Technology for Collision Repair

Plasma cutting technology has revolutionized collision repair in the automotive body shop industry. Unlike traditional methods like flame or laser cutting, plasma cutting uses an ionized gas to precisely and efficiently cut through various materials, including metal panels and auto glass. This innovative approach offers numerous benefits for both repair technicians and vehicle owners.

When it comes to plasma cutting collision repair, understanding the technology is key. Plasma cutters generate a high-velocity jet of ionized gas that can cut through metals with remarkable speed and accuracy. This precision not only ensures effective dent removal but also minimizes heat impact, preserving the structural integrity of the vehicle’s body. In an automotive body shop, this translates to faster turnaround times and higher quality repairs, making it a game-changer in the field of auto glass repair and overall collision restoration.

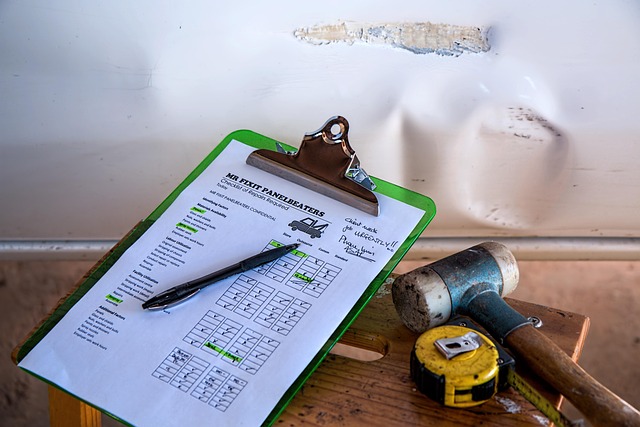

Pre-Cutting Preparation and Safety Measures

Before initiating any plasma cutting collision repair process, meticulous preparation and a robust safety plan are non-negotiable. The automotive body shop must be equipped with specialized tools and trained personnel to handle plasma cutters, which generate intense heat and high-pressure gas flows. This pre-cutting phase involves several critical steps: thoroughly inspecting the damaged vehicle to identify hidden dents or structural weaknesses, preparing the work area by ensuring adequate ventilation and clearing a safe space around the repair zone, and gathering all necessary materials like plasma cutters, protective gear, and specialized solutions for dent repair.

Safety measures are paramount to protect both workers and the environment. This includes donning appropriate personal protective equipment (PPE), such as safety goggles and gloves, to safeguard against flying debris. The automotive body shop should have procedures in place for controlling sparks and preventing fire hazards, especially when dealing with metal components of Mercedes Benz repair or other high-value vehicles. Effective communication among the team is crucial to maintain a safe environment during this precise yet potentially dangerous collision repair process.

Post-Cutting Process and Quality Assurance Checks

After the plasma cutting process is complete, several crucial steps ensure the quality and precision of the collision repair work. The post-cutting routine involves meticulous inspection to verify that the cut lines are accurate and aligned as per the original design. This includes checking for any deviations or inconsistencies in the cut edges, ensuring they are clean and free from debris.

Quality assurance checks are a vital part of the process, especially in luxury vehicle repairs where precision is paramount. Professionals use specialized tools to measure the dimensions and ensure the vehicle body repair aligns perfectly with the manufacturer’s specifications. These checks guarantee that the plasma cutting collision repair job meets the highest standards, ensuring a seamless fit and finish when the parts are reassembled, be it for a standard auto body repair or a more intricate luxury vehicle repair.

Plasma cutting collision repair is a precise and effective method that combines advanced technology with meticulous preparation and post-cutting checks. By understanding the process, from leveraging plasma cutting’s capabilities to ensuring quality assurance, you can expect superior results in collision repair. This modern approach streamlines repairs, enhances safety, and offers lasting solutions for various vehicle damage scenarios.