Adopting heated windshield replacement techniques significantly streamlines automotive glass repair, especially in colder regions, by using defrost-capable adhesives for quick installations. This method reduces vehicle downtime and damage risks from temperature changes. Selecting the right adhesive requires considering environmental conditions, compatibility with windshield materials, and durability against frost and moisture. Using advanced application techniques, including cleaned surfaces, precise tools, and proper alignment, enhances the effectiveness and longevity of heated windshield replacements.

“Uncover the secrets to efficient defrosting with advanced tips on using defrost-capable windshield adhesives. In today’s climate, a quick and reliable heated windshield replacement process is essential for safety and convenience. This guide explores the benefits and step-by-step process of this modern solution.

We’ll help you navigate the market by identifying key factors in choosing the right adhesive, ensuring optimal performance. From application techniques to achieving long-lasting results, these advanced strategies will revolutionize your approach to heated windshield replacement.”

- Understanding Heated Windshield Replacement: Benefits and Process

- Choosing the Right Defrost-Capable Windshield Adhesive: Key Factors

- Advanced Application Techniques for Optimal Results

Understanding Heated Windshield Replacement: Benefits and Process

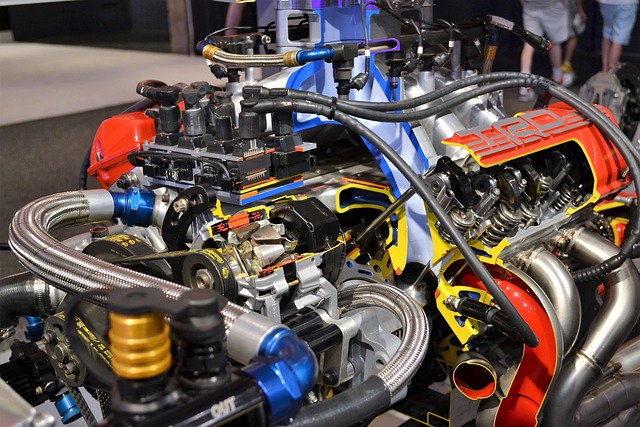

The process of heated windshield replacement offers a modern solution to a common problem, especially in colder climates. Traditional windshield replacement can be a lengthy and challenging task, often requiring extensive preparation and waiting times due to the need for the glass to reach room temperature. In contrast, defrost-capable windshield adhesives and heated replacement techniques streamline this process significantly. By utilizing specialized adhesives that remain flexible in cold temperatures, technicians can install new windshields without the time-consuming cooling step, making it an efficient and cost-effective option.

This innovative approach provides several benefits for both vehicle owners and repair shops. Heated windshield replacements reduce downtime, ensuring drivers can get back on the road faster. Moreover, this method minimizes the risk of damage caused by temperature variations during installation, which is a common issue with traditional replacement techniques, often requiring additional services like tire services or vehicle dent repair to address subsequent issues. By embracing heated windshield replacement, repair facilities can enhance their service offerings, attracting customers who value convenience and timely solutions for vehicle collision repair.

Choosing the Right Defrost-Capable Windshield Adhesive: Key Factors

When selecting a defrost-capable windshield adhesive for your heated windshield replacement, several key factors come into play. Firstly, consider the environmental conditions in which it will be used; adhesives designed for colder climates may not perform optimally in warmer regions, and vice versa. Secondly, check the compatibility with various windshield materials to ensure it adheres effectively without causing damage. The ability to withstand frost and moisture is non-negotiable, making it a core requirement for any adhesive used in such environments.

Additionally, look into the product’s durability and resistance to environmental stressors, especially if your car is often exposed to harsh weather conditions or involves frequent car collision repair. Reputable brands offering car restoration and body shop services typically provide detailed information on their adhesives’ performance under different scenarios, which can guide your choice for optimal results during heated windshield replacement.

Advanced Application Techniques for Optimal Results

When applying defrost-capable windshield adhesives for a heated windshield replacement, utilizing advanced application techniques can significantly enhance the overall performance and longevity of the adhesive bond. For optimal results, ensure that the surface is thoroughly cleaned and free from any debris or contaminants before starting. A smooth, dry surface is crucial for effective adhesion. Consider using specialized cleaning solutions designed for car bodywork services to remove any residue or oils that could hinder the adhesive’s grip.

For precise application, employ tools like precision spatulas or applicators specifically tailored for auto dent repair. This ensures accurate placement and control over the adhesive’s thickness. Maintain a consistent gap between the windshield and the vehicle’s frame during installation, as recommended by the manufacturer. Proper alignment not only guarantees an airtight seal but also optimizes heat distribution, which is essential for curing the adhesive during cold weather conditions, thereby enhancing your auto maintenance routine.

Heated windshield replacement offers a swift and efficient solution for icy conditions, making defrost-capable adhesives an essential tool. By understanding the benefits of this process and selecting the right adhesive with key factors in mind, you can achieve optimal results. Advanced application techniques, such as ensuring proper surface preparation and using the correct amount of adhesive, will further enhance the durability of your repair. With these tips, you’re well-equipped to navigate icy roads with confidence, knowing your vehicle’s windshield is secure against frosty challenges.